A Rare Earth Permanent Magnet Powder Precise Powder Supply and Feeding System

A rare-earth permanent magnet and powder technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of poor accuracy and low efficiency of manual feeding, to avoid leakage and waste, good practicability, and ensure accuracy The effect of sex and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

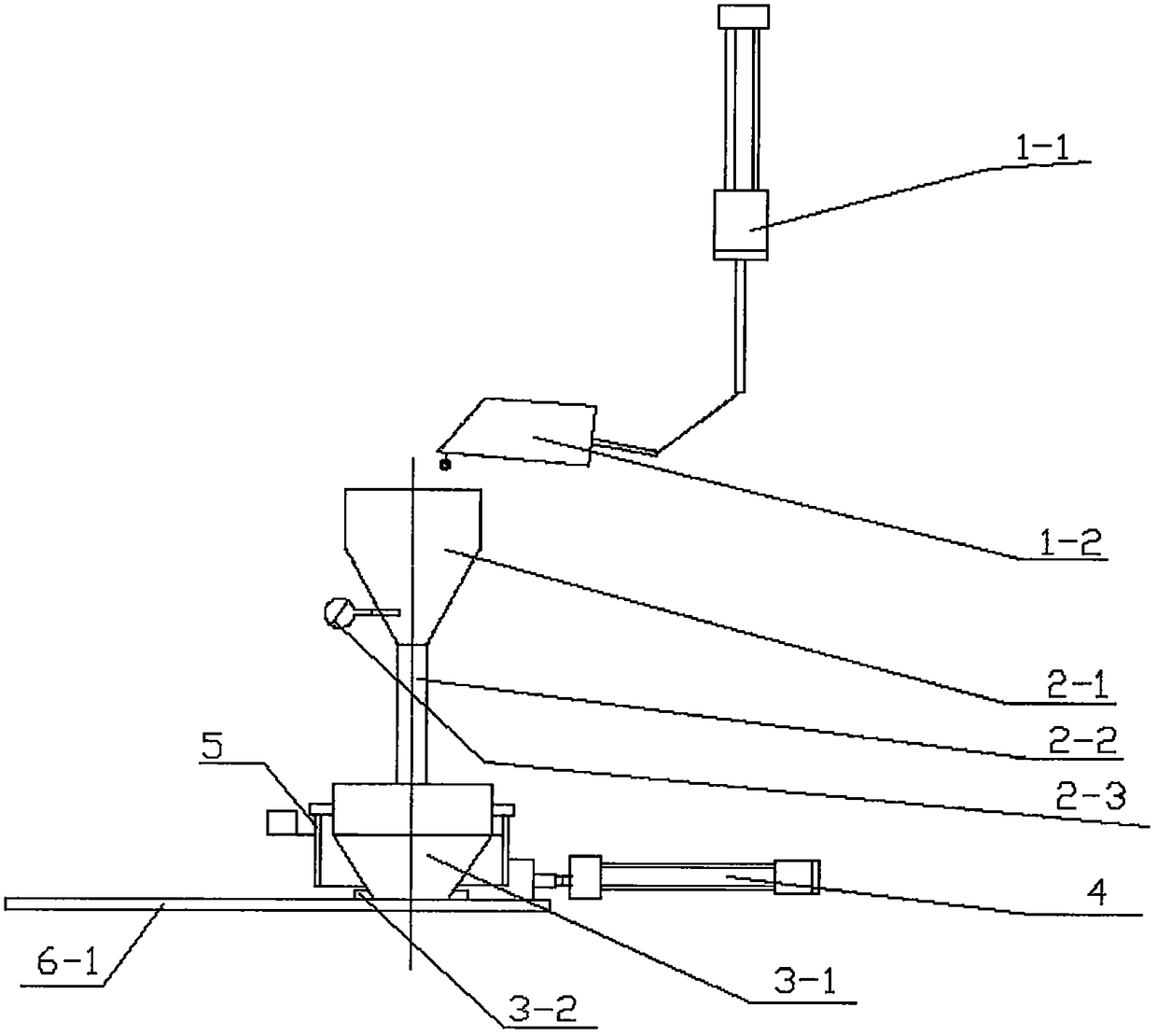

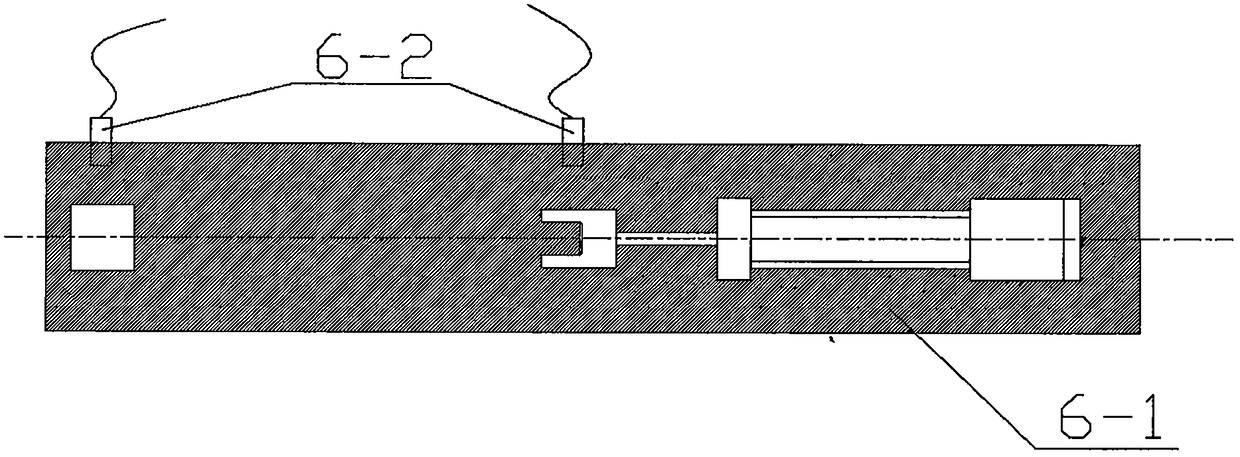

[0029] The present invention will be further described below in conjunction with the drawings and embodiments.

[0030] A precise powder feeding and feeding system for rare earth permanent magnet powder. Because the rare earth permanent magnet powder is easy to be oxidized, excessive oxygen content will seriously affect the performance of the prepared magnet. Therefore, in the best embodiment, the magnetic field orientation molding device and the system need to be placed in an inert gas atmosphere. If it is exposed to the atmosphere to operate, it is necessary to add antioxidants to the magnetic powder before the pressing process to prevent excessive oxidation of the magnetic powder.

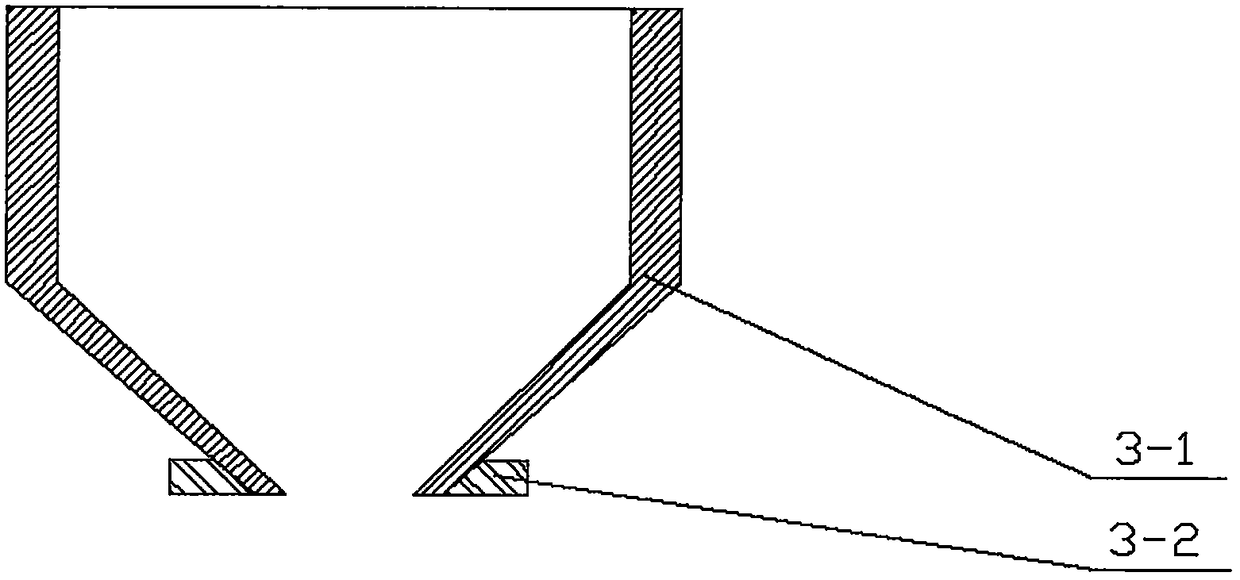

[0031] Such as figure 1 As shown, the weighed magnetic powder is added to the weighing shovel 1-2, and the tapered hopper 2-1 is located below the discharge end of the weighing shovel 1-2, so that the magnetic powder can be poured into the weighing shovel 1-2. The top opening of the cone hopper 2-1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com