High-precision gear centering and clamping device based on inner hole centering and machining method of high-precision gear centering and clamping device

A technology of clamping device and clamping method, applied in the direction of gear teeth manufacturing device, metal processing equipment, belt/chain/gear, etc., can solve the problems of poor stability, cumbersome operation steps, not suitable for mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

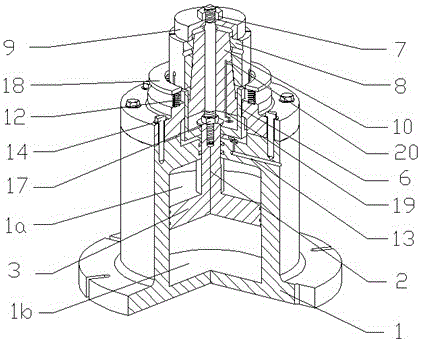

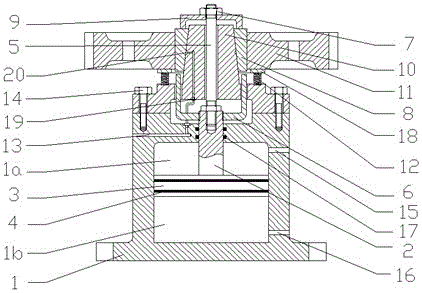

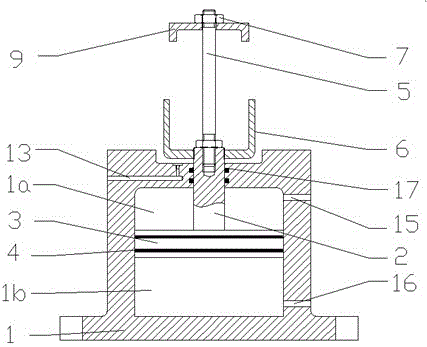

[0052] The invention discloses a fast centering clamping device and a processing method for a high-precision gear that grinds teeth with an inner hole as a centering reference.

[0053] Such as Figure 1~Figure 4 As shown, a high-precision gear centering clamping device based on inner hole centering includes a hydraulic module for the overall drive of the device and an expansion sleeve centering clamping module for gear clamping. The expansion sleeve centering The clamping module is arranged on the upper end of the hydraulic module. The expansion sleeve centering clamping module includes a cone base 10 and an elastic expansion sleeve 8 matching it. The elastic expansion sleeve 8 is movably sleeved on the On the truncated truncated base 10 and under the drive of the hydraulic module, the axial movement is completed, and the elastic expansion sleeve 8 can convert the relative axial movement between it and the truncated truncated base 10 into its own Radial deformation to realiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com