Bit blank grinding method and automatic bit sharpening machine

A grinding method and automatic technology, which is applied to machine tools, grinding machines, grinding/polishing equipment, etc., which are suitable for grinding the edge of workpieces, can solve problems such as low work efficiency, inability to realize processing automation, and high labor intensity, and achieve grinding efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

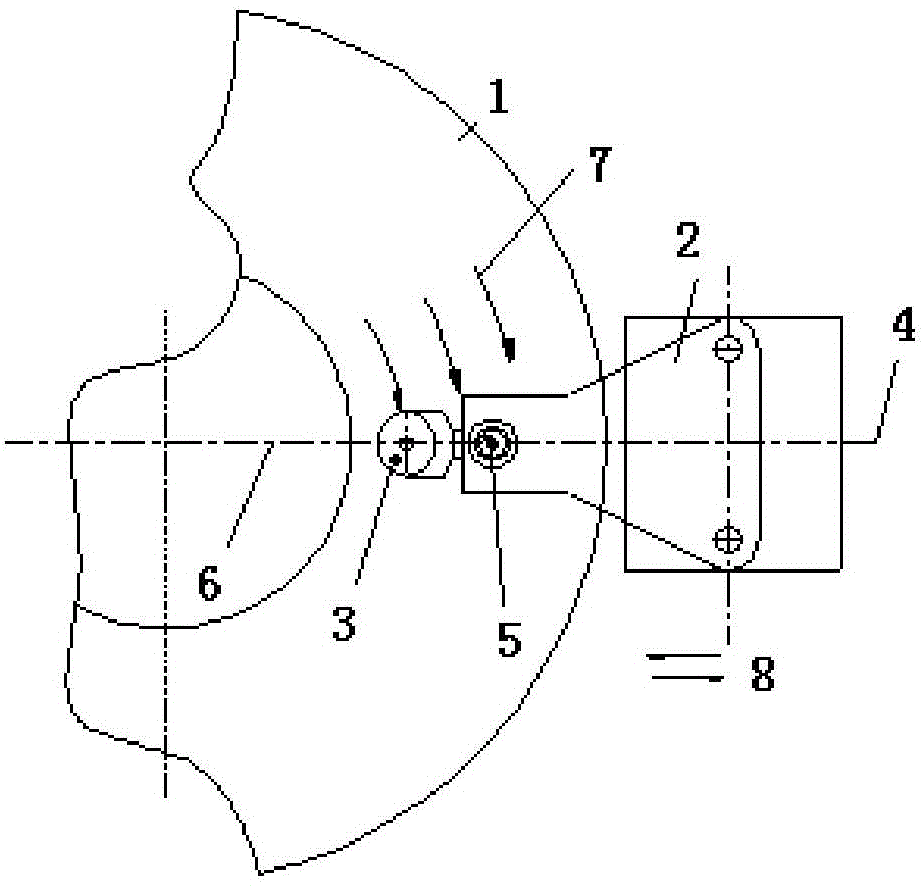

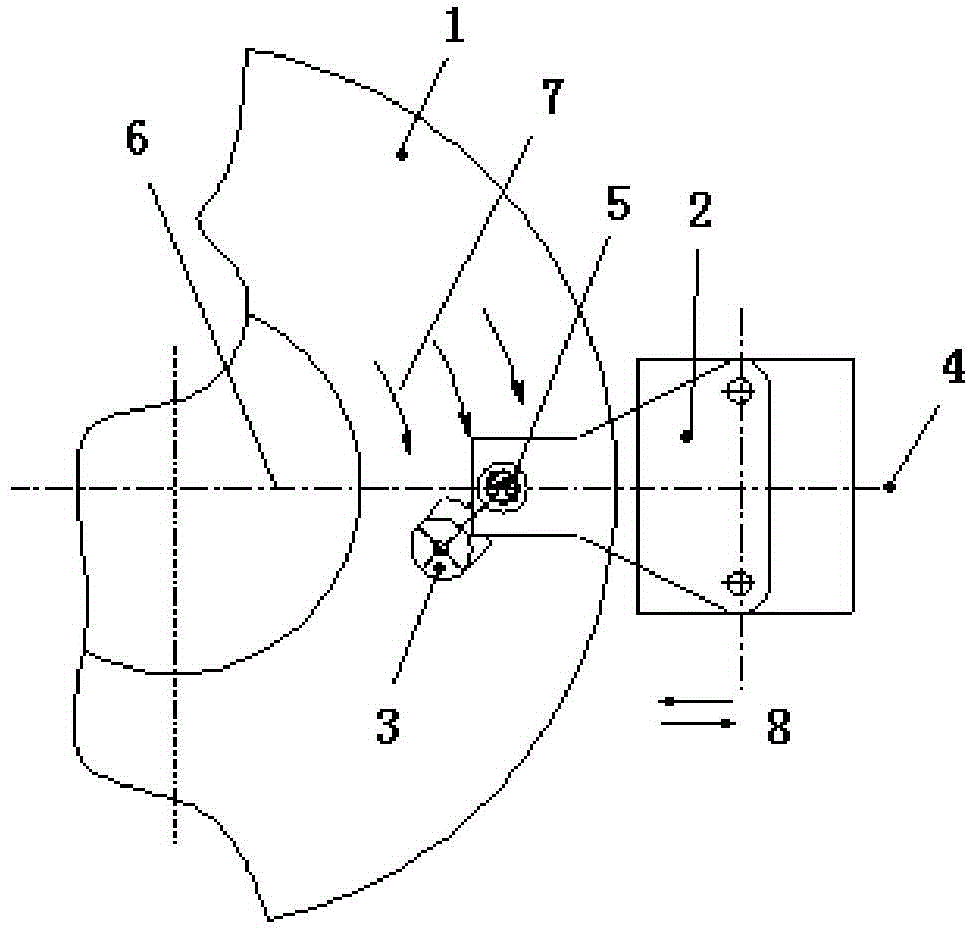

[0011] In the diamond grinding method disclosed in the application of the present invention, the drill blank is clamped on the head 3 of the drill blank fixture, and is ground in contact with the grinding disc 1, and the drill blank clamp drives the drill blank to grind along the path away from the center of the grinding disc circle along the extension line, which is convenient In terms of mechanism realization, the path can be a grinding path that deviates from the center of the grinding disc and crosses the surface of the grinding disc in a straight line along the horizontal axis of the fixture.

[0012] The automatic grinding machine for realizing the above-mentioned blank grinding method, the basic structure includes a grinding disc assembly and a blank clamp assembly, the bracket of the blank clamp assembly is fixed on one side of the horizontal grinding disc 1 coated with diamond powder on the surface, and the grinding machine The whole can adopt an improved structure wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com