A portable powder dense stacking molding device and its application

A molding device and portable technology, applied in the field of powder tableting, can solve the problems of inability to accurately control the sample preparation pressure, inability to ensure the consistency of the compactness, affecting the accuracy of the XRF method, etc., so as to improve the operability and accuracy, It is not easy to disintegrate and break, and the effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

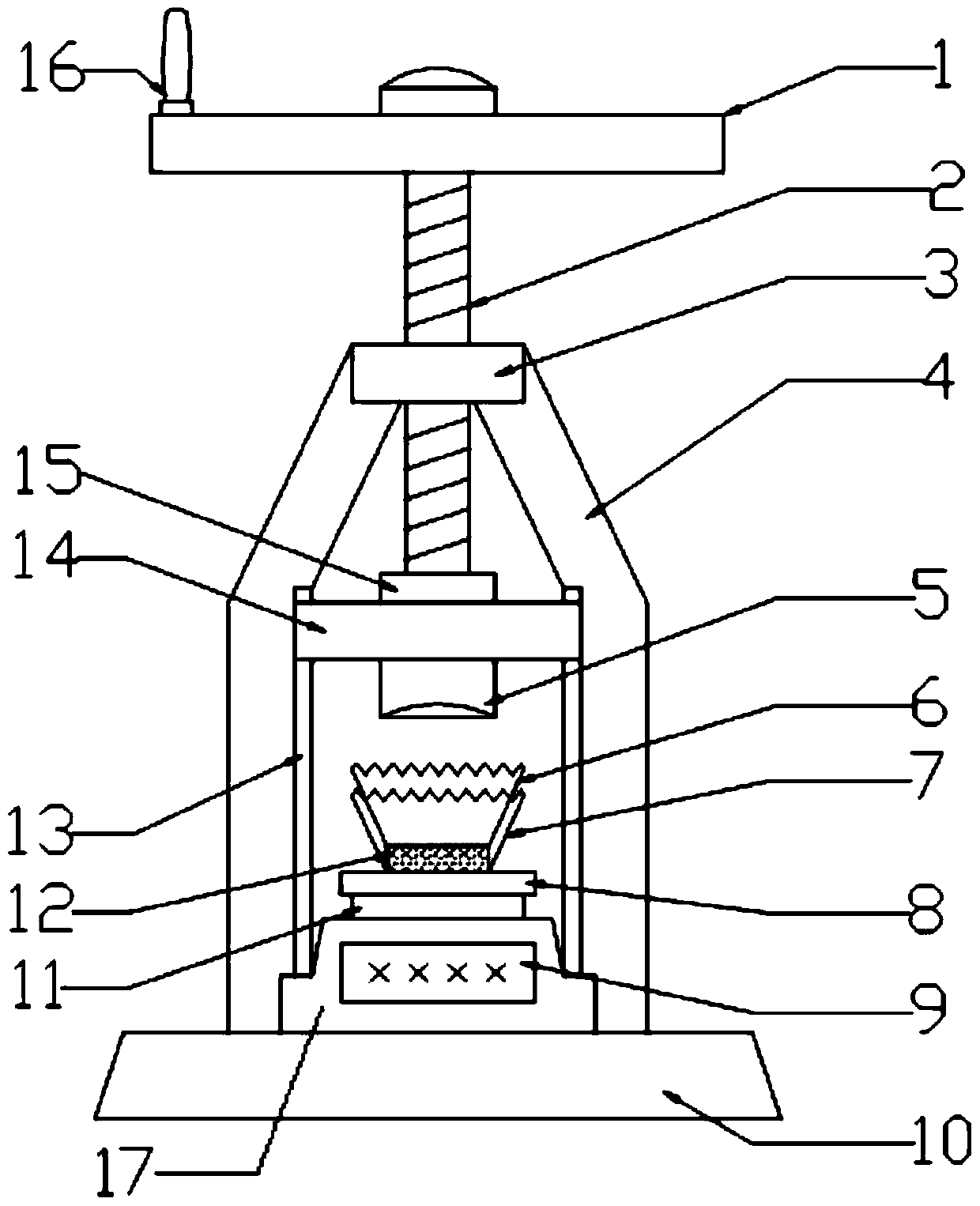

[0045] Such as figure 1 As shown, a portable powder dense stacking molding device includes a base 10, a support 4 arranged on the base 10, an upper pressing mold 5 arranged on the support 4 reciprocally movable along the vertical direction, and an upper pressing The feed guide mechanism used in conjunction with the mold 5, the sample pressing part located below the upper pressing die 5 and opposite to the upper pressing die 5, and the digital display support mechanism arranged at the bottom of the sample pressing part, the upper pressing die 5 is driven by a screw The mechanism can be reciprocated up and down and set on the bracket 4; when working, put the powder sample 12 into the sample pressing part, and place the sample pressing part on the digital display support mechanism, turn the screw transmission mechanism, and press the mold 5. Driven by the transmission mechanism of the screw 2, it moves down along the feed guide mechanism, and performs extrusion molding on the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com