A kind of atmospheric pressure preparation method of silica airgel

A silicon dioxide and aerogel technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of lengthy solvent replacement treatment, poor performance parameters of aerogel products, etc., and is conducive to industrial production, reducing costs, shortening The effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

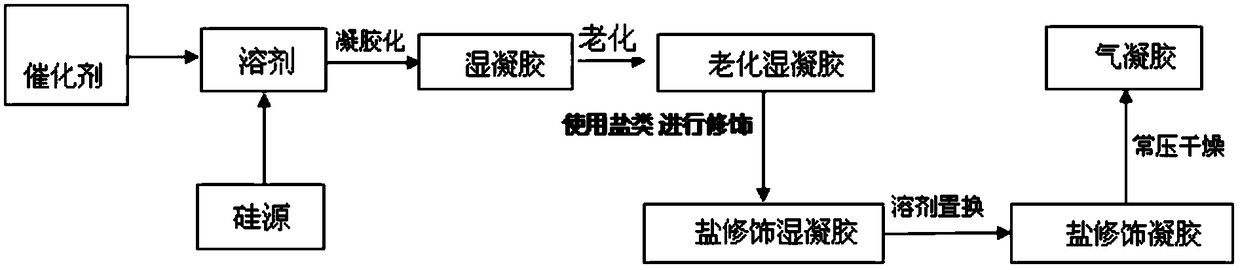

[0028] The invention provides a normal-pressure preparation method of silica airgel, comprising:

[0029] modifying the aged silica wet gel by using a metal salt compound to obtain the modified wet gel, and the metal salt compound can coordinate with a hydroxyl group;

[0030] performing solvent replacement on the modified wet gel to obtain a modified gel;

[0031] The modified gel is dried under normal pressure to obtain a silica airgel.

[0032] The invention uses metal salt compounds to modify the aged silicon dioxide wet gel to obtain the modified wet gel. In the present invention, the aged silica wet gel is preferably modified in a metal salt compound solution to obtain the modified wet gel. In the present invention, the modification temperature is preferably 20°C-30°C, more preferably 22°C-28°C, most preferably 24°C-26°C. In the present invention, the modification time is preferably 20 hours to 30 hours, more preferably 22 hours to 28 hours, most preferably 24 hours t...

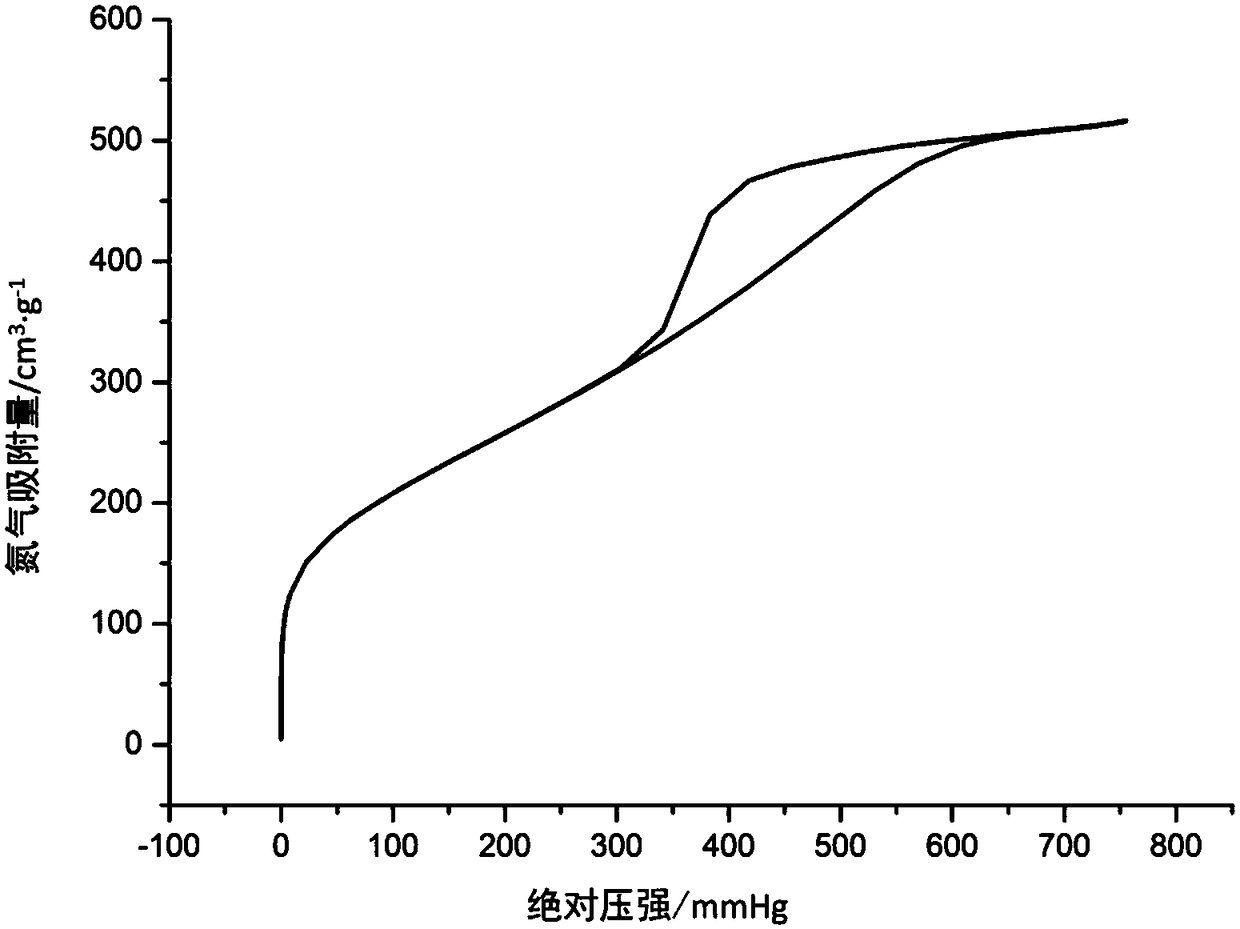

Embodiment 1

[0062] Add 42mL of alcohol (ETOH), 26.8mL of tetraethyl orthosilicate (TEOS) and 6.9mL of N-N dimethylformamide (DMF) into a 250mL two-necked flask, place it in an oil bath at 60°C, and adjust the rotation speed to 500 rpm / min, oil bath magnetic stirring 10min, to obtain the mixture;

[0063] Add H to the mixture 2 O 6.4mL and concentrated hydrochloric acid continued to be magnetically stirred in an oil bath at 60°C for 1h, and the pH value was adjusted to 3 to obtain an intermediate product;

[0064] Move the intermediate product into a 250mL beaker, drop concentrated ammonia water, adjust the pH value to 9, adjust the rotation speed to 100 rpm, and let it stand to obtain a silica wet gel;

[0065] The ETOH, TEOS, H 2 The molar ratio of O and DMF is 1:6:3:0.75.

[0066] The silica wet gel is placed in the mother liquor for aging twice, each time for 24 hours, and a new mother liquor needs to be replaced after each completion to obtain the aged silica wet gel;

[0067] Ad...

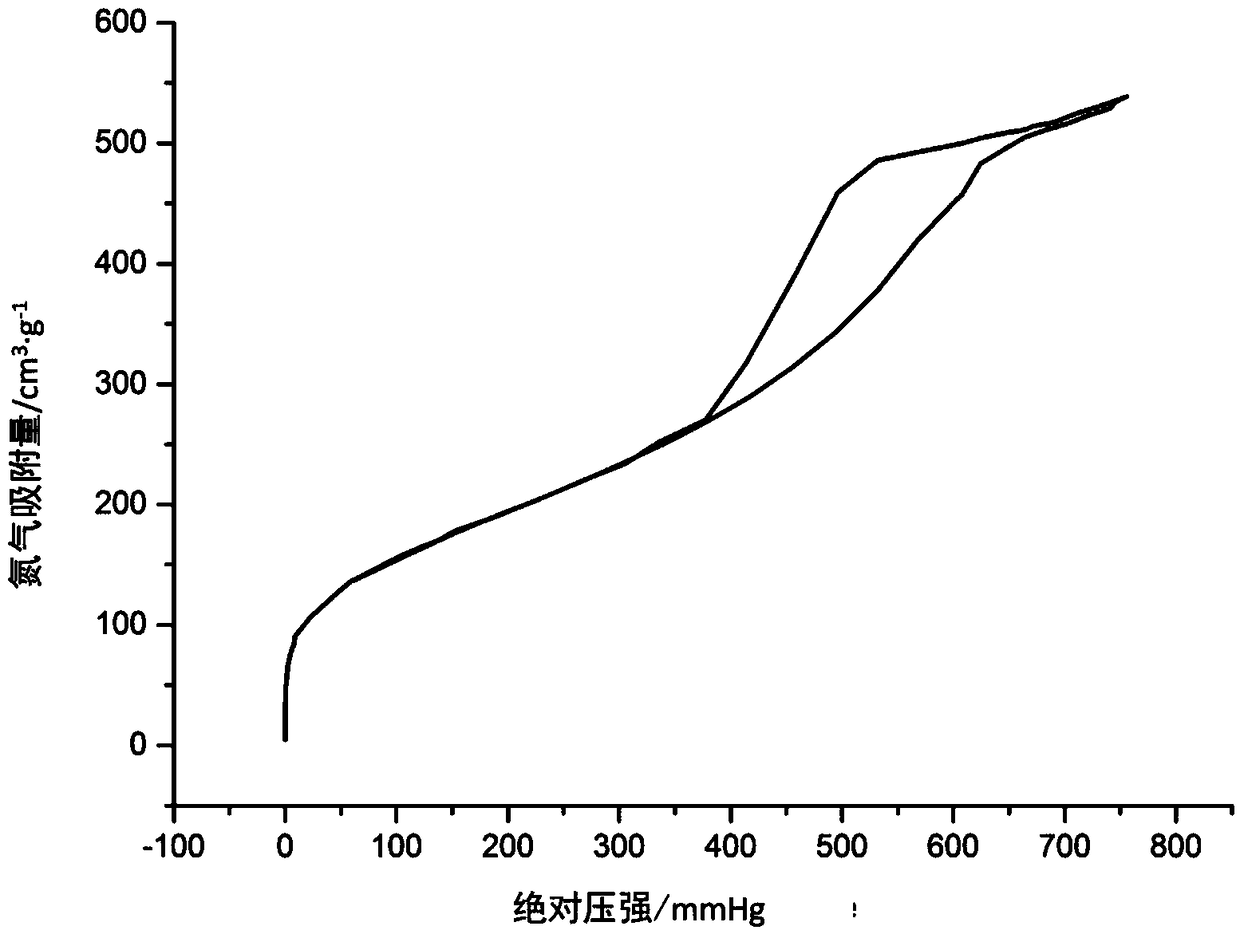

Embodiment 2

[0073]Add 42mL of alcohol (ETOH), 26.8mL of tetraethyl orthosilicate (TEOS) and 6.9mL of N-N dimethylformamide (DMF) into a 250mL two-necked flask, place it in an oil bath at 60°C, and adjust the rotation speed to 700 rpm / min, oil bath magnetic stirring 30min, obtain mixture;

[0074] Add H to the mixture 2 O 6.4mL and concentrated hydrochloric acid continued to stir magnetically in an oil bath at 60°C for 2h, and adjusted the pH value to 3 to obtain an intermediate product;

[0075] Move the intermediate product into a 250mL beaker, drop concentrated ammonia water, adjust the pH value to 7, adjust the rotation speed to 100 rpm, and let it stand to obtain a silica wet gel;

[0076] Described TEOS, ETOH, H The molar ratio of O and DMF is 1:6:3:0.75

[0077] The silica wet gel is placed in the mother liquor for aging twice, each time for 24 hours, and a new mother liquor needs to be replaced after each completion to obtain the aged silica wet gel;

[0078] Add 0.9987g of cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com