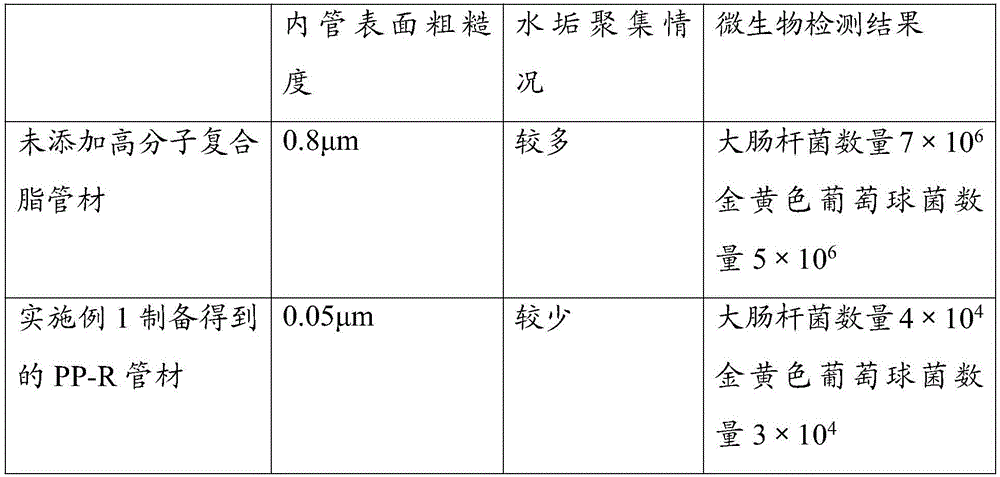

Low-surface roughness propylene random copolymer (PP-R) pipe and preparation method thereof

A PP-R, roughness technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of rough inner wall, affecting water quality and sanitation, poor fluidity, etc., achieve low inner surface roughness, ensure water quality and sanitation, and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

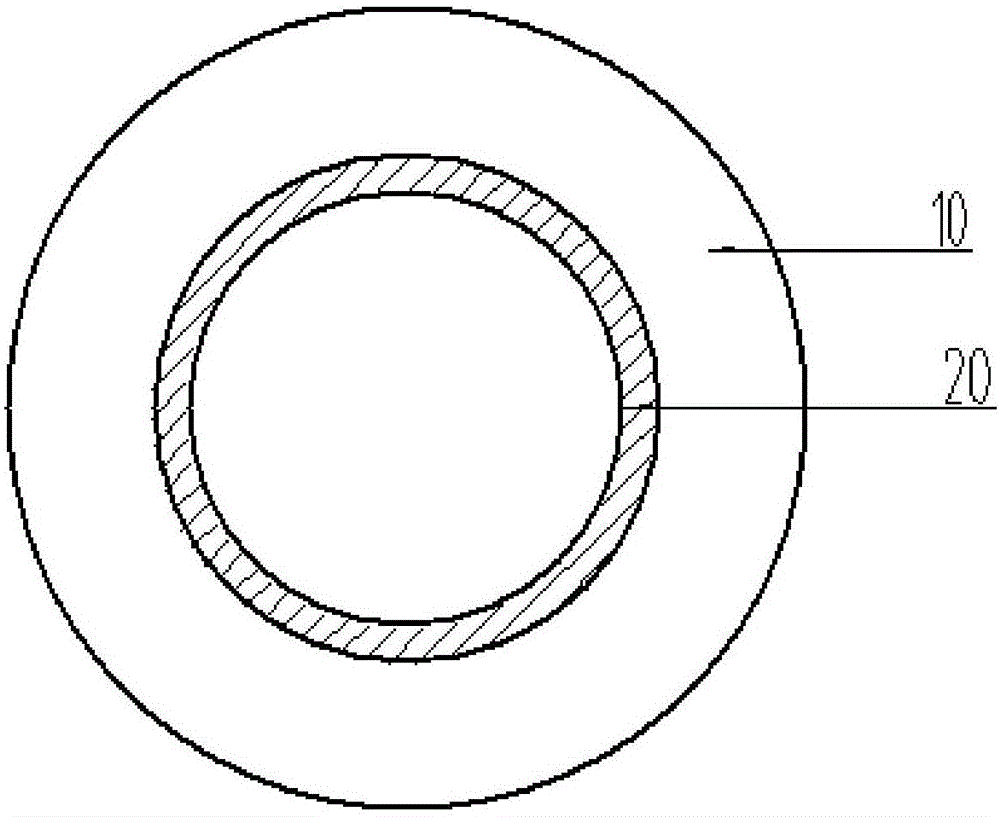

[0035] Prepare a low surface roughness PP-R pipe, pipe specification S3.220*2.8, the PP-R pipe is divided into two layers, from inside to outside: low surface roughness inner layer 20 and PP-R outer layer 10. The thickness of the inner layer is 0.3mm, and the thickness of the outer layer of PP-R is 2.5mm.

[0036] The preparation method is as follows:

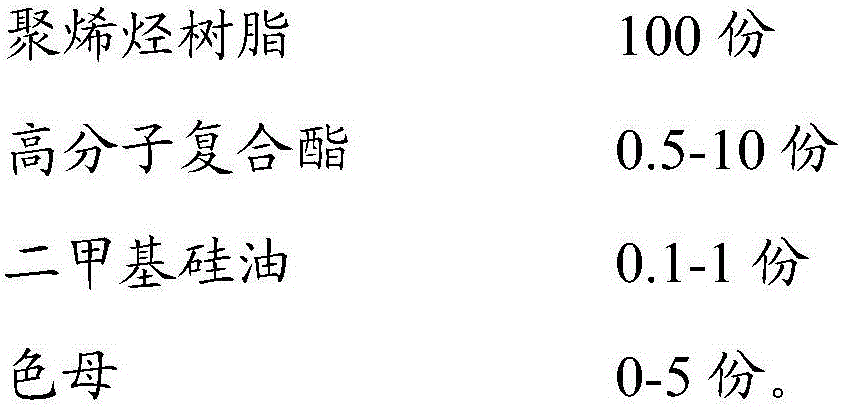

[0037] (1) First, mix polypropylene resin PP, polymer compound grease, dimethyl silicone oil and color masterbatch according to the ratio of parts by mass of 100:5:0.5:2, fully stir with a high-speed mixer for 5-10min, and then pass through the twin-screw The extruder is extruded and granulated, and the processing temperature is controlled between 160-200°C to obtain inner layer granules.

[0038] (2) Add 3wt% white masterbatch to the PP-R resin raw material, fully stir with a high-speed mixer for 5-10min, then extrude and granulate through a twin-screw extruder, and control the processing temperature between 170-220°C to obta...

Embodiment 2

[0045] Prepare a low surface roughness PP-R pipe, the pipe specification S3.225*3.5, the PP-R pipe is divided into two layers, from inside to outside: the inner layer with low surface roughness and the outer layer of PP-R, The thickness of the inner layer is 0.5mm, and the thickness of the outer layer of PP-R is 3.0mm.

[0046] The preparation method is as follows:

[0047] (1) First mix polypropylene resin PP, polymer compound grease, dimethyl silicone oil and color masterbatch according to the ratio of parts by mass of 100:6:1:3, fully stir with a high-speed mixer for 5-10min, and then pass through the twin-screw The extruder is extruded and granulated, and the processing temperature is controlled between 160-200°C to obtain inner layer granules.

[0048] (2) Add 3% white masterbatch to the PP-R resin raw material, fully stir with a high-speed mixer for 5-10min, then extrude and granulate through a twin-screw extruder, and control the processing temperature between 170-220°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com