Oil Filtration System for Ceramic Tile Press

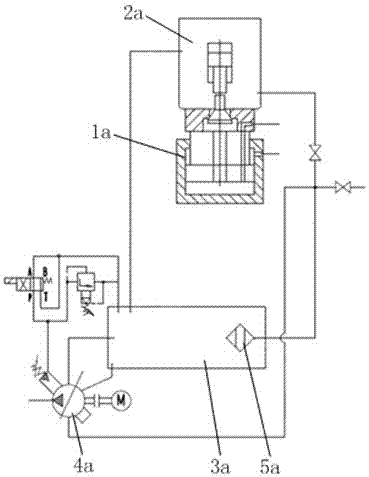

A technology for a ceramic brick press and a filtration system, which is applied to fluid pressure actuating system components, mechanical equipment, fluid pressure actuating devices, etc., can solve the problem of small filter element dirt holding capacity, increased energy consumption of ceramic brick press, and short replacement cycle. and other problems, to achieve the effect of increasing the filtration capacity, reducing the probability of rusting, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

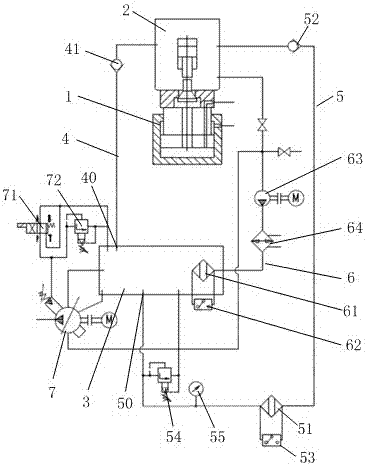

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

[0022] See attached figure 2 , the invention discloses an oil filtration system for a ceramic brick press, comprising an oil cylinder 1, an upper oil tank 2, and a lower oil tank 3, the oil cylinder 1 is connected to the upper oil tank 2, and also includes a first oil outlet pipeline 4, a second oil outlet pipeline Road 5 and oil inlet pipeline 6, the main oil pump 7 of the present invention sucks oil from the lower oil tank 3 and outputs high-pressure oil to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com