Contact type scanning probe for micro-nano three-coordinate measuring machine

A technology of a three-coordinate measuring machine and a scanning probe, applied in the field of micro-nano testing, can solve the problems of low detection sensitivity and precision of strain gauges, difficult installation and adjustment, etc., and achieves simple structure, good time stability and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In this embodiment, the structural form of the contact scanning probe of the micro-nano three-coordinate measuring machine is:

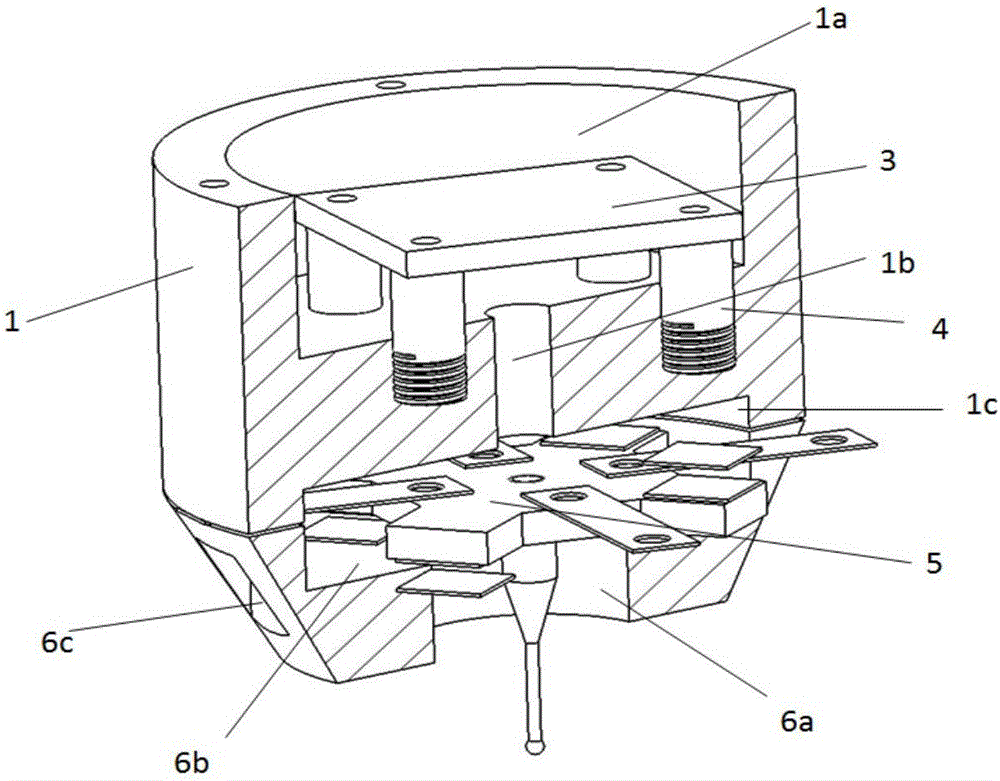

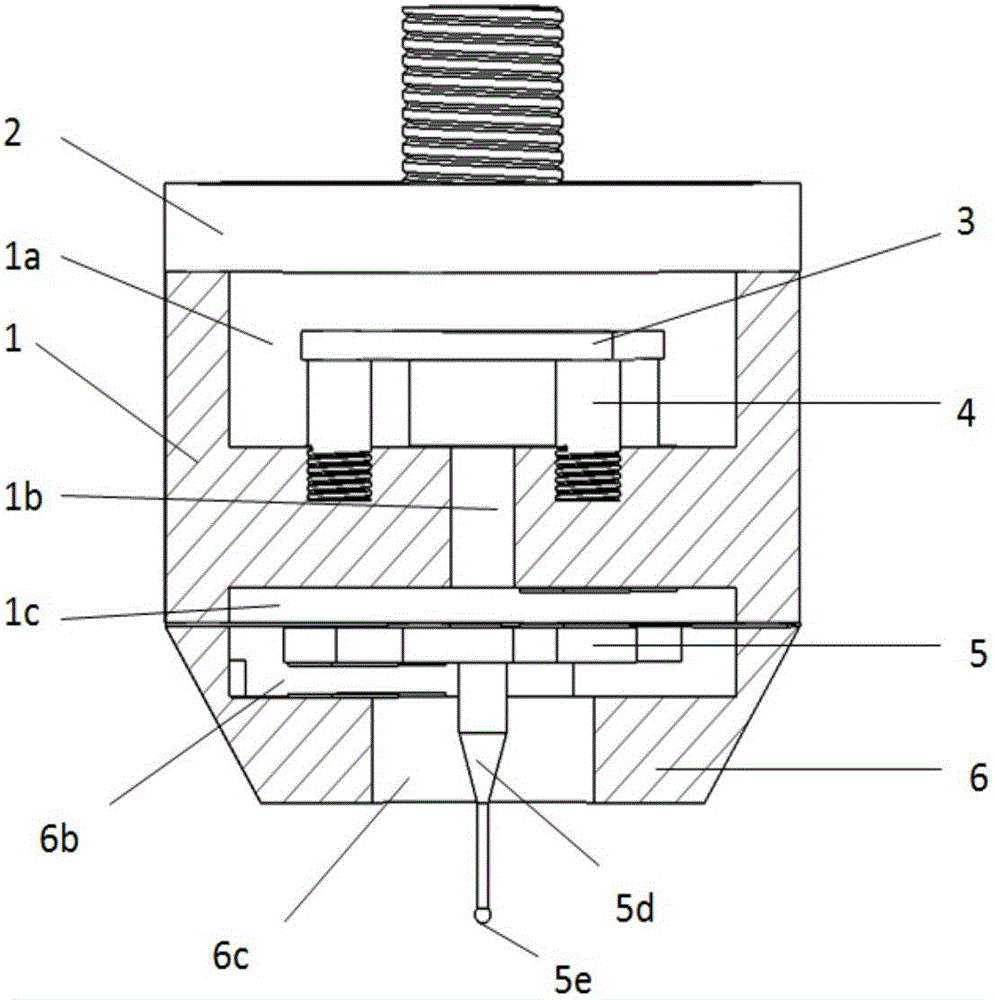

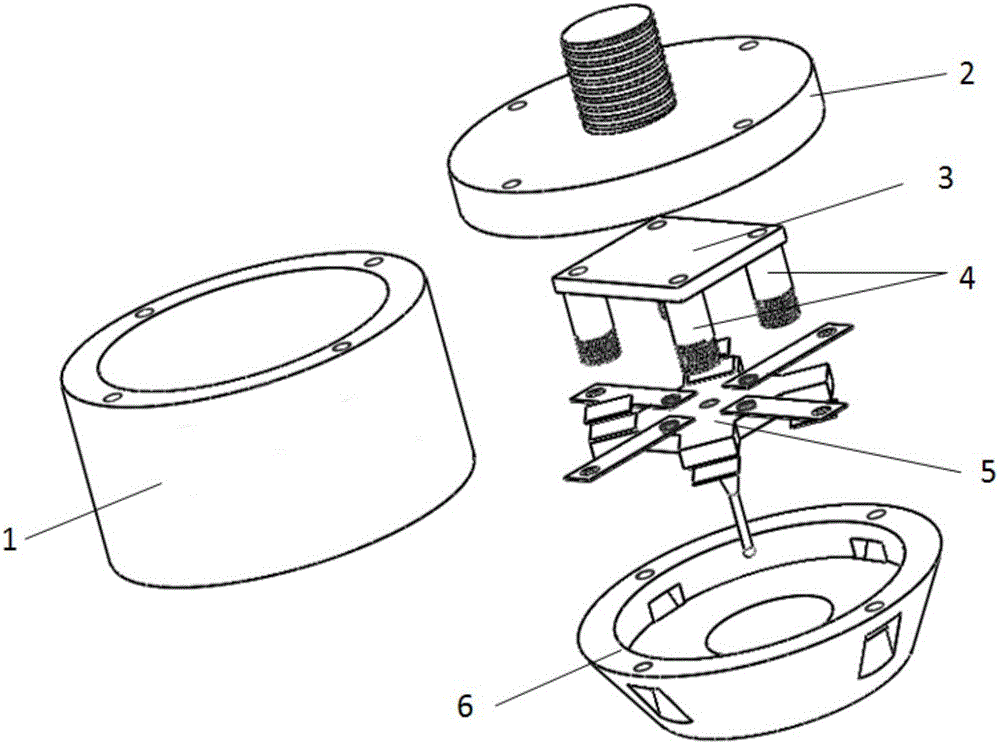

[0029] Such as figure 1 , figure 2 with image 3 As shown, the probe housing is composed of a cylindrical body 1 and a base 6 in the shape of a frustum of a cone received at the bottom of the cylindrical body 1, and a probe unit and a measuring unit are arranged in the probe housing.

[0030] Such as Figure 4 , Figure 5 with Image 6 As shown, the probe unit is provided with a suspension piece 5a in the shape of a "ten" in the inner cavity 6b of the base 6, and cantilever springs are respectively connected to the top surface of the suspension piece 5a and the angle between adjacent cantilevers. sheet 5b, the other end of the cantilever reed 5b is connected to the top annular end face of the base 6, forming the suspension structure of the suspension sheet 5a in the inner cavity of the base 6; The probe 5d of the ruby measuring ball 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com