Laser high-temperature liquid height measurement and control system and method

A high-temperature liquid and liquid level technology, which is applied in the direction of liquid/fluid solid measurement, measuring devices, liquid level indicators, etc., can solve the problems of complex algorithms and low detection accuracy, and achieve the effect of simplifying the detection algorithm and improving the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

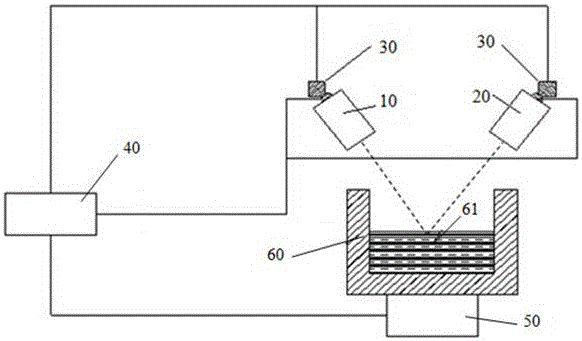

[0043] Embodiment 1: A laser high-temperature liquid height measurement and control system.

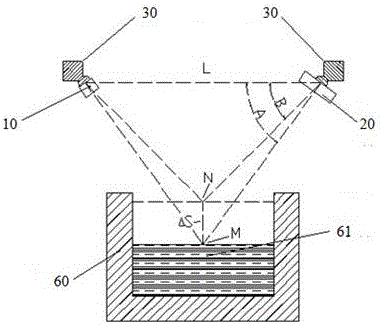

[0044] refer to figure 1 As shown, a laser high-temperature liquid height measurement and control system includes: a laser transmitter 10 and a laser receiver 20 located above the liquid level of the liquid to be measured and oppositely arranged, and the laser transmitter 10 and the laser receiver 20 are relatively The normal direction of the center is arranged symmetrically. A panel for receiving the laser beam is arranged on the laser receiver 20 facing the end face of the laser transmitter 10. A midpoint is set in the middle of the panel. Only when the laser beam emitted by the laser transmitter 10 is reflected To the midpoint of the panel, the controller starts to calculate, otherwise it will always drive the laser emitter 10 to change the laser emission angle;

[0045] The drive unit 30 is used to drive the laser transmitter 10 and the laser receiver 20 to rotate simultaneously....

Embodiment 2

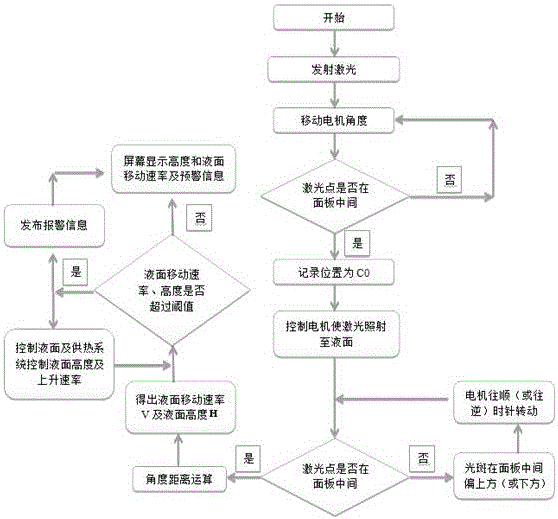

[0057] Embodiment 2: A method for measuring and controlling the height of a laser high-temperature liquid.

[0058] refer to image 3 As shown, a method for measuring and controlling the height of a laser high-temperature liquid comprises the following steps:

[0059] S1. Signal zeroing of the laser transmitter 10 and the laser receiver 20: the controller 40 sends an instruction to make the laser transmitter 10 generate a laser beam of a specific frequency, and controls the drive unit 30 to make the laser transmitter 10 and the laser receiver 20 level state, so that the laser beam emitted by the laser transmitter 10 is irradiated to the center of the panel of the laser receiver 20 for zero adjustment, and after the zero adjustment is completed, record the current position as the zero position;

[0060] S2. High-temperature liquid level measurement: turn on the liquid delivery pump and send the liquid level of the liquid to be measured to a point M where the liquid level heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com