A micro-stressed support structure for large-aperture mirrors

A large-diameter mirror and support structure technology, applied in the field of optical engineering, can solve the problems of difficult to eliminate or reduce the surface shape of the optical components of the system, the failure of the performance indicators of the optical system, and the influence of the surface shape accuracy of the reflector, so as to reduce defects. Effect, easy assembly, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

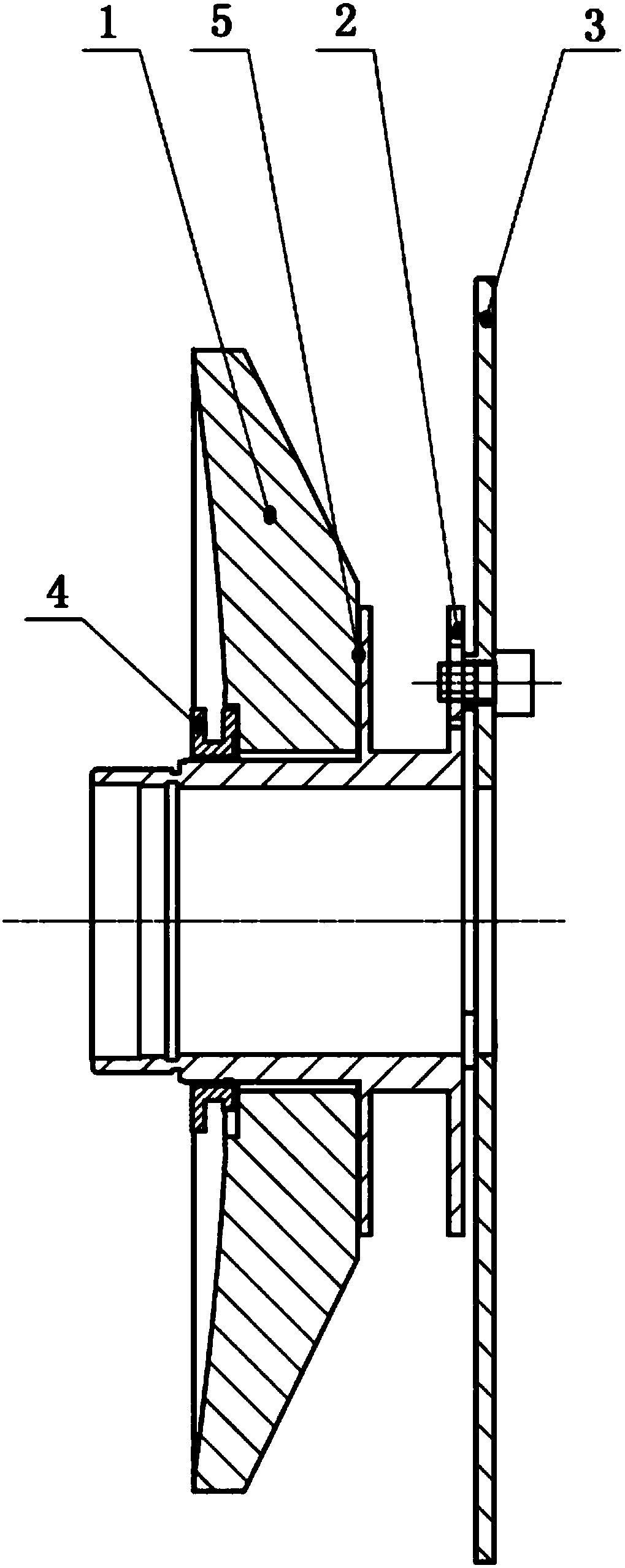

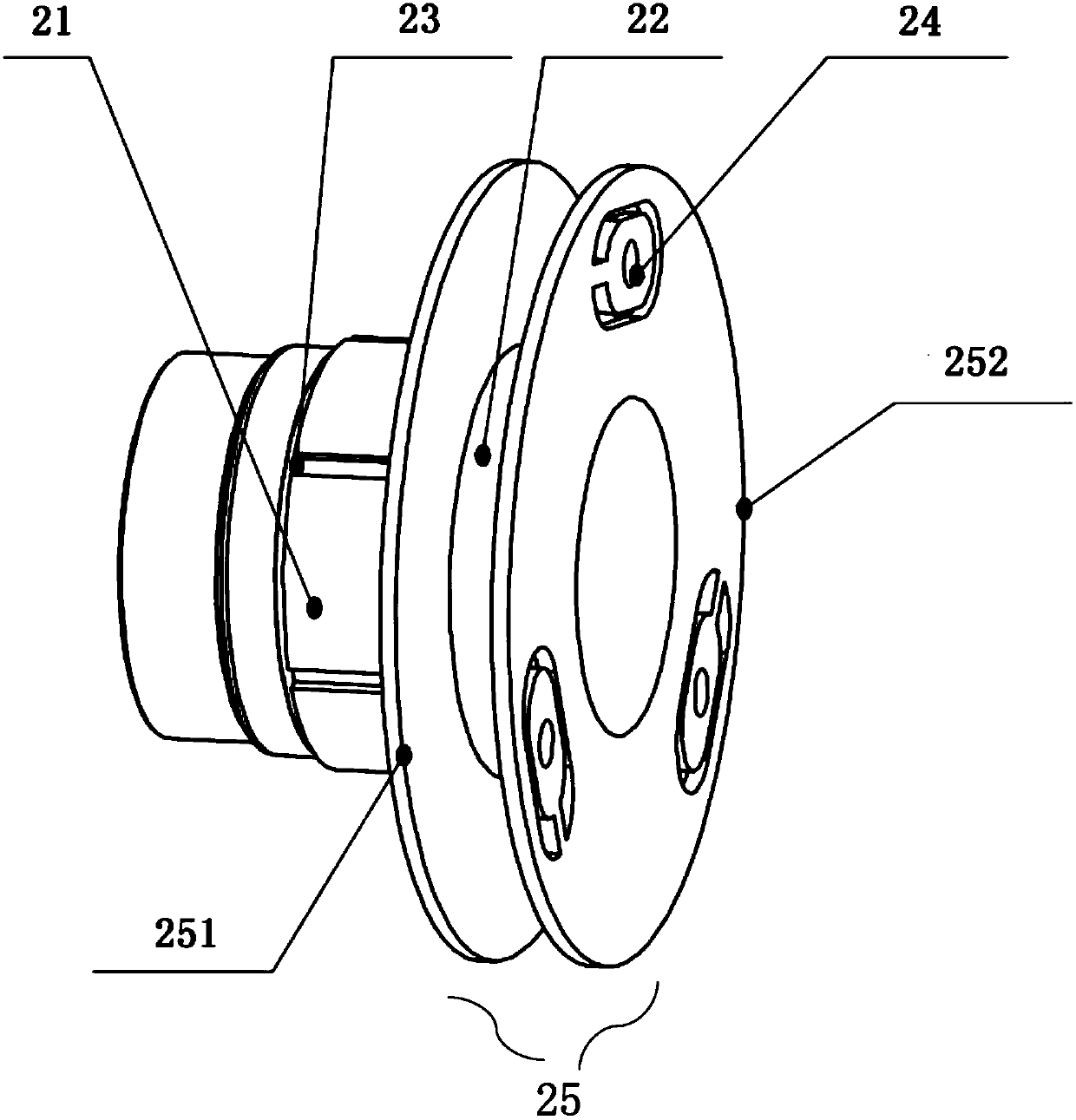

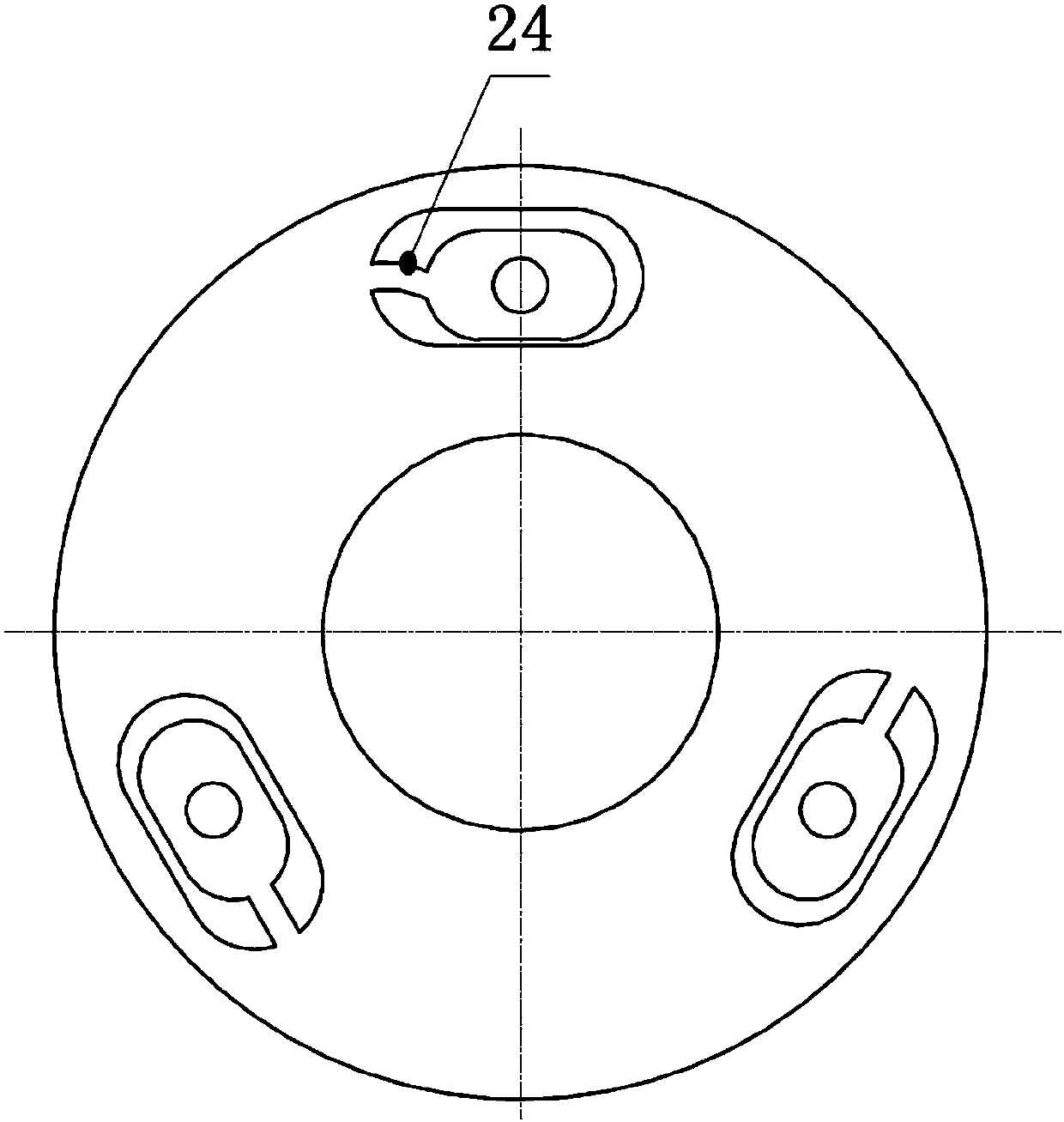

[0026] Such as figure 1 , figure 2 with image 3 As shown, the micro-stress support structure of the large-diameter mirror provided by the present invention includes a large-diameter mirror 1 , a mirror holder 2 and an optical system base plate 3 . The mirror base 2 is made of a metal material or a composite material with a low coefficient of thermal expansion, and it includes a mirror base base plate 25 and a mirror base central axis 21; the mirror base base plate 25 includes a front end base plate 251 and a rear end base plate 252. The first stress relief grooves 22 are provided between the end base plates 252 ; the central axis 21 of the mirror base is a stepped axis, and a plurality of second stress relief grooves 22 are provided in the area matching with the large-aperture mirror 1 .

[0027] When assembling, pass the central axis 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com