Asphalt mixing station monitoring and management system based on IoT technology

An Internet of Things technology and asphalt mixing technology, applied in the field of engineering construction quality monitoring system, can solve the problems of informatization and intelligentization of expressway production, untimely data processing of mixing stations, and slow information transmission speed, etc., to achieve Improve production efficiency and quality, realize real-time monitoring, and reduce the effect of loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

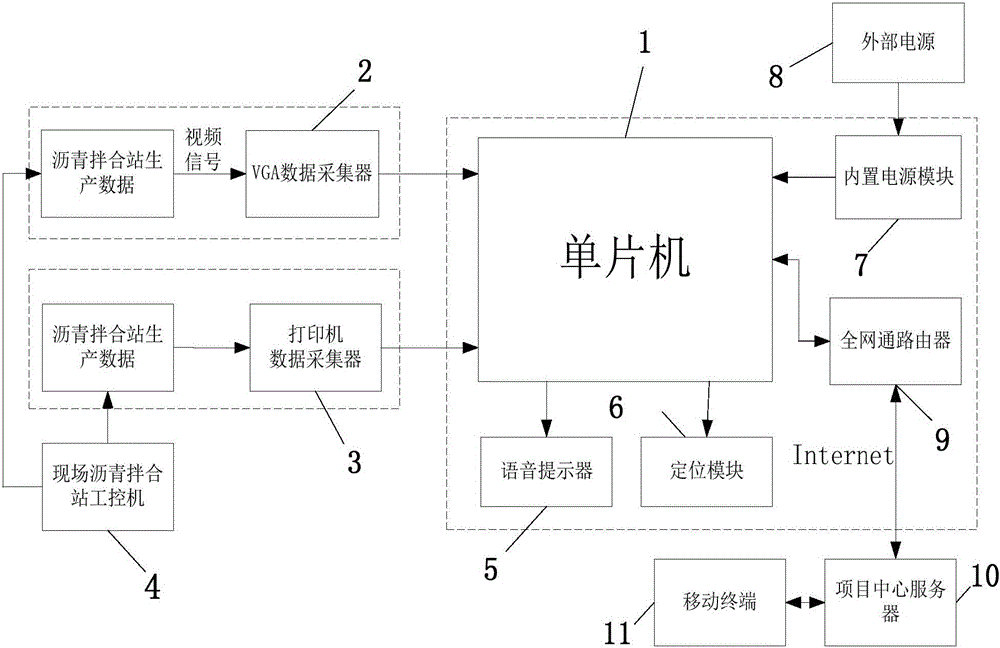

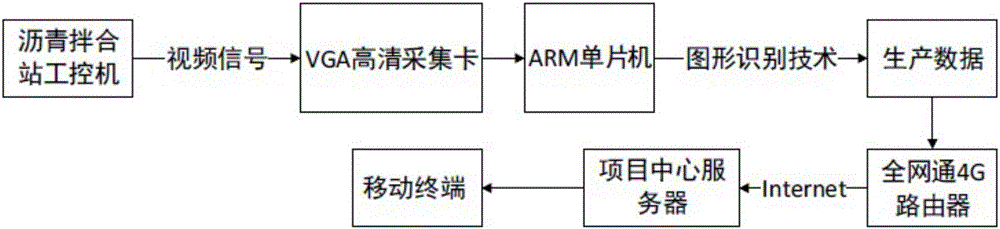

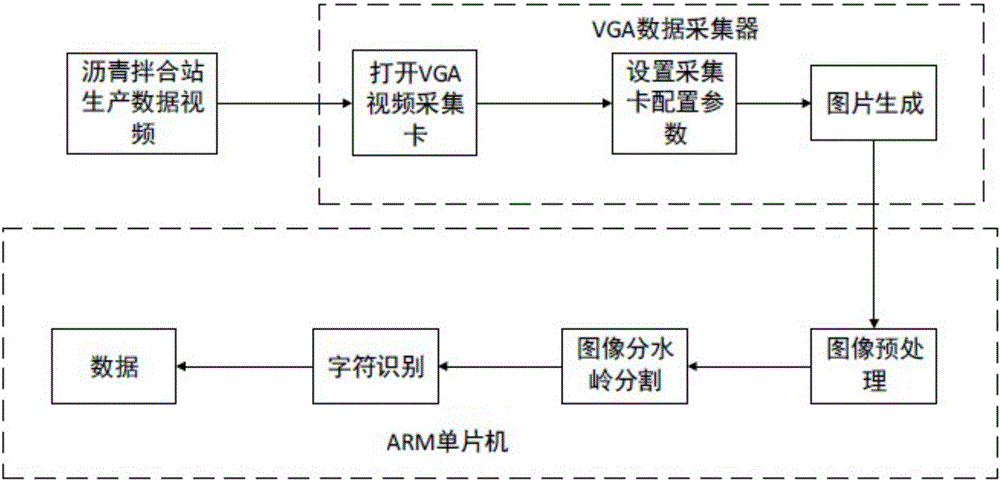

[0019] see figure 1 , the production data storage of the on-site asphalt mixing plant is generally stored in the database of the industrial computer of the asphalt mixing plant. Different asphalt mixing plant manufacturers have different regulations. Domestic and foreign asphalt mixing plant manufacturers generally It is not allowed to directly collect the production data of the batching plant. The present invention structurally includes a VGA data collector 2, a printer data collector 3, a single-chip microcomputer 1, a built-in power supply module 7, a router 9, a voice prompt module 5, a positioning module 6, a project center server 10, and a mobile terminal 11. The VGA data collector 2 is connected to the single-chip microcomputer 1 through the RS232 interface, and the collected production data is transmitted to the ARM single-chip computer; the printer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com