Alternating-current ice-melting electric reactor applicable to contact net of high-speed rail and design method of alternating-current ice-melting electric reactor

A reactor and catenary technology, applied in the direction of inductors, variable inductors, circuits, etc., can solve problems such as coil insulation layer breakage, coil airtight performance reduction, high-speed rail safety hidden dangers, etc., to achieve no magnetic saturation Phenomenon, satisfying the conditions of use, and ensuring the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

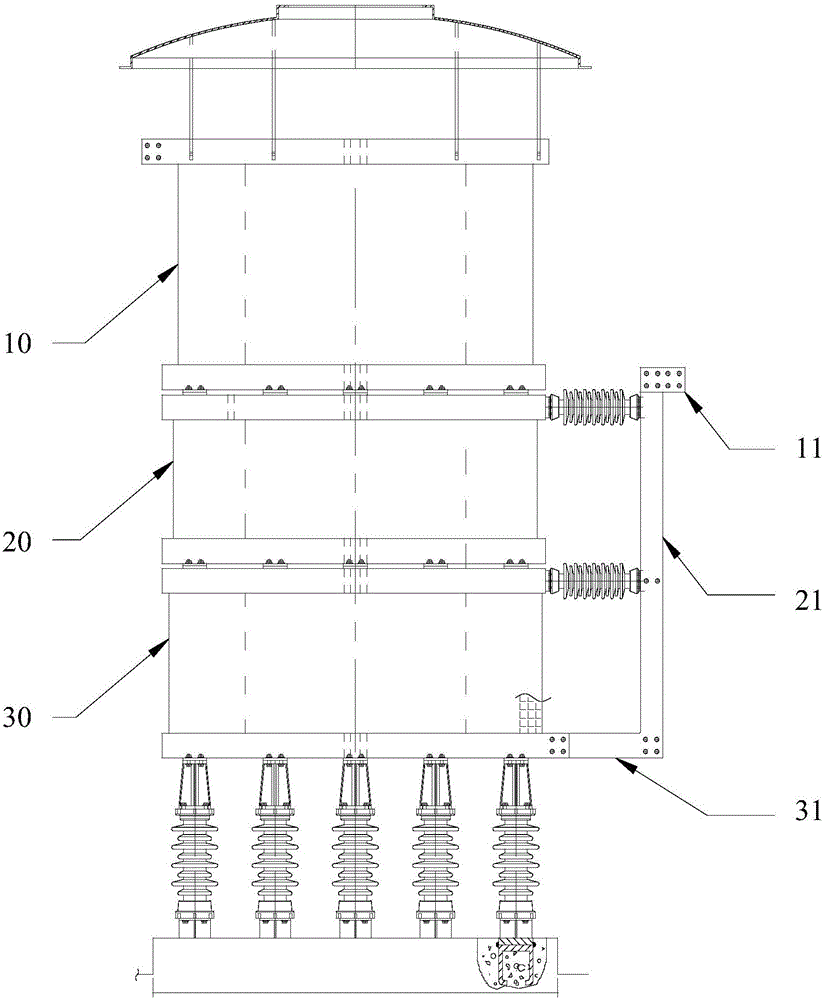

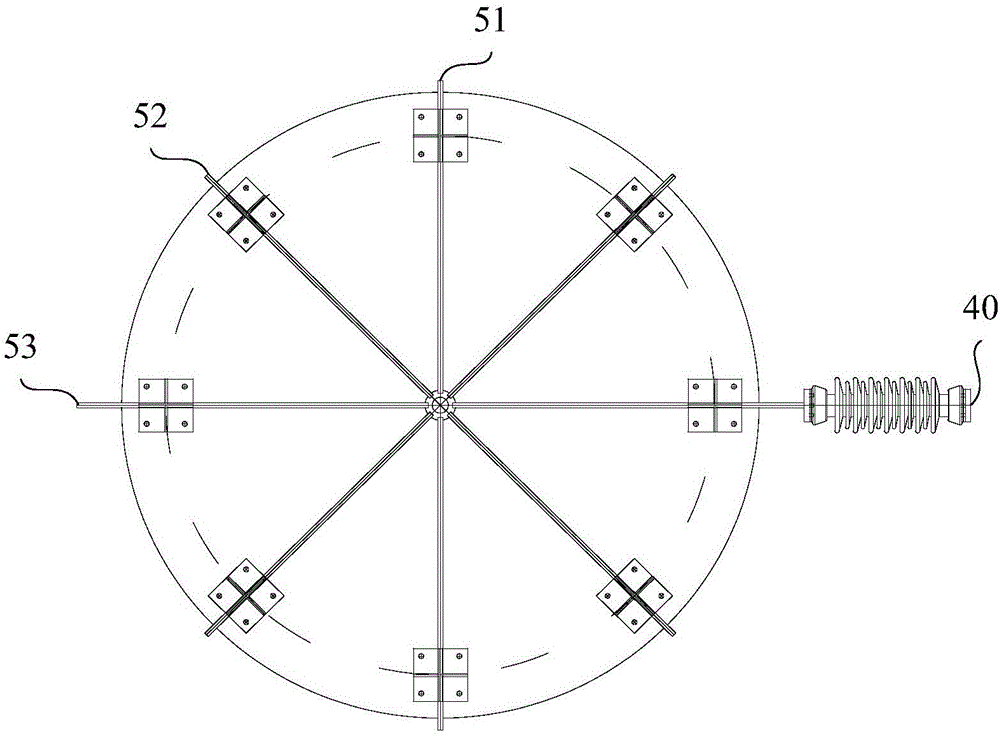

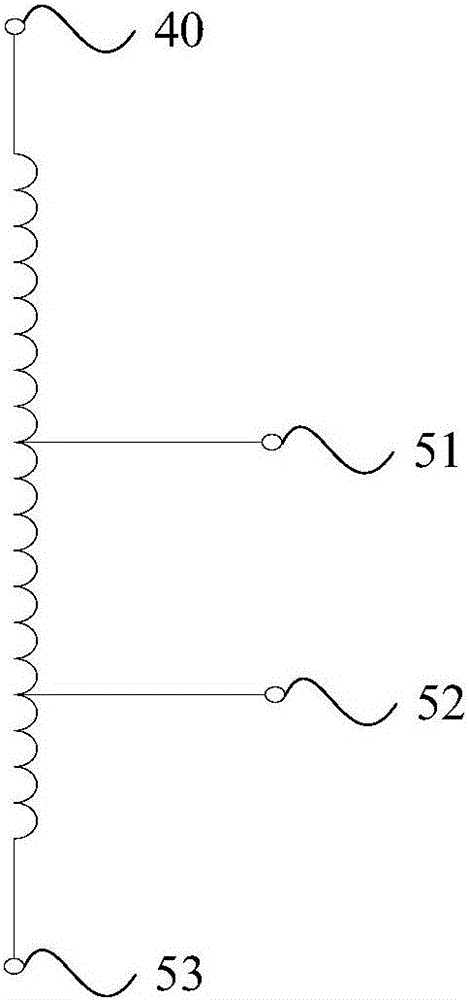

[0027] Please refer to figure 1 and figure 2 as shown, figure 1 It is a schematic diagram of the appearance structure of the AC melting reactor applied to the high-speed rail catenary of the present invention, figure 2 It is the view of the foot position of the present invention. The dry-type air-core reactor includes: an upper coil 10, a middle coil 20 and a lower coil 30, wherein the upper coil 10, the middle coil 20 and the lower coil 30 are respectively provided with an upper The connection row 11, the middle connection row 21 and the lower connection row 31, the upper connection row 11, the middle connection row 21 and the lower connection row 31 have a common incoming line terminal 40, and the incoming li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com