Epoxy resin dry-type wall bushing

A technology of epoxy resin and wall-piercing bushings, applied in the direction of electrical components, etc., can solve problems such as poor sealing performance and anti-fouling performance, endangering personal and equipment safety, and unfinished after-sales service, achieving short processing cycle and long-term Low running cost and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

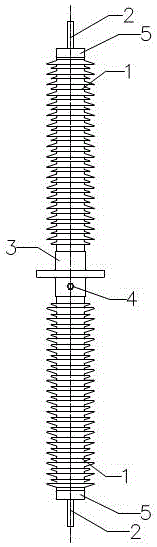

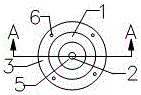

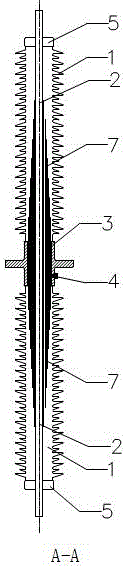

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0018] figure 1 , figure 2 and image 3 An epoxy resin dry-type wall-penetrating bushing is shown, including an insulator 1 that is mainly made of an outdoor epoxy resin added with auxiliary materials such as a curing agent and a toughening agent. The inner center of the insulator 1 is provided with a The carrier body 2 is provided with a metal flange 3 in the middle of the outside, and a metal cover 5 is provided at each end; the side of the metal flange 3 is in the shape of a "cross", and its thermal expansion coefficient is similar to that of the insulator 1; for convenience Installation, the horizontal part on the metal flange 3 is provided with a plurality of mounting holes 6 and an air vent; the insulator 1 at both ends of the metal flange 3 is in the shape of a multi-layer shed, and the insulator 1 is multi-layered. The multi-layer shed-like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com