Wiring method of differential signal line and PCB

A technology of differential signal lines and wiring methods, applied in the directions of circuit substrate materials, printed circuits, electrical components, etc., can solve the problems of high cost, long wiring time, and occupying a lot of wiring space, and achieve the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

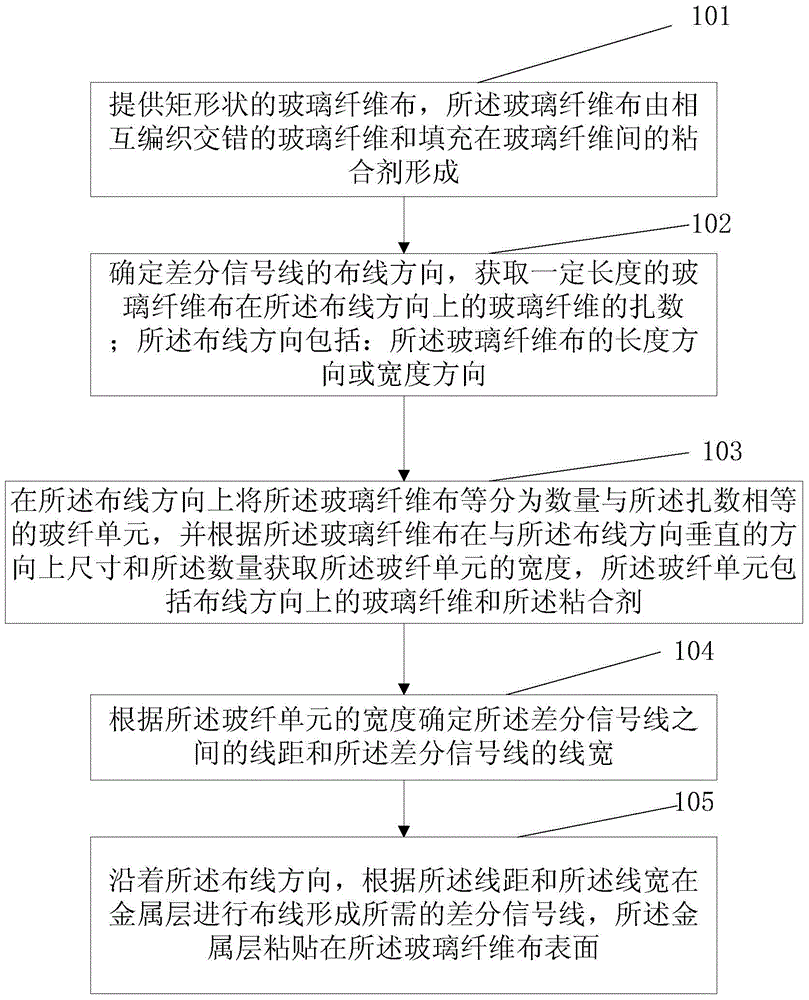

[0055] Considering the technical problems of high cost, large wiring space and long wiring time in the existing wiring method for controlling differential signal delay, this embodiment provides a wiring method for differential signal lines, such as figure 1 shown, including the following steps:

[0056] Step 101: Provide a rectangular glass fiber cloth, the glass fiber cloth is formed by weaving interlaced glass fibers and an adhesive filled between the glass fibers.

[0057] In this embodiment, the rectangular glass fiber cloth includes: interlaced glass fibers, the glass fibers in the length direction of the rectangular glass fiber cloth are called weft threads, and the glass fibers in the width direction are called warp threads.

[0058] Step 102: Determine the wiring direction of the differential signal line, and obtain the number of glass fiber bundles of the glass fiber cloth in the wiring direction; the wiring direction includes: the length direction or the width direct...

Embodiment 2

[0118] In this embodiment, the wiring method described in the first embodiment is introduced by wiring in the warp direction, which includes the following steps:

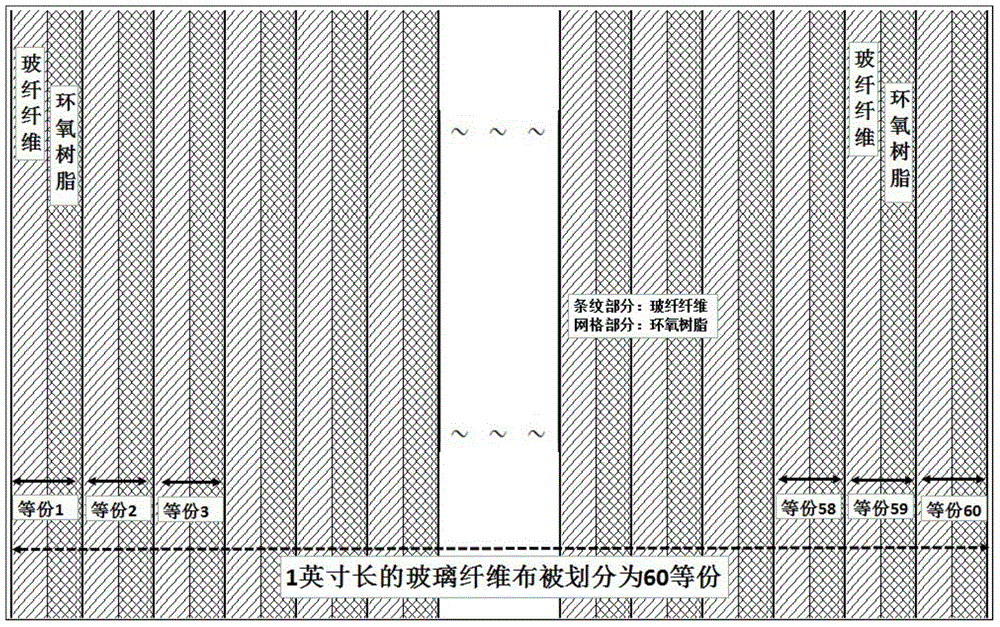

[0119] Step S01: First, according to the needs of high-speed signals and lamination, select the appropriate specification of glass fiber cloth, check the number of bundles according to the IPC standard, and obtain the number of bundles of warp and weft threads of this glass fiber specification as m×n, from which each Equivalent value X, meridian direction X=1000 / m(mil), refer to figure 2 ;

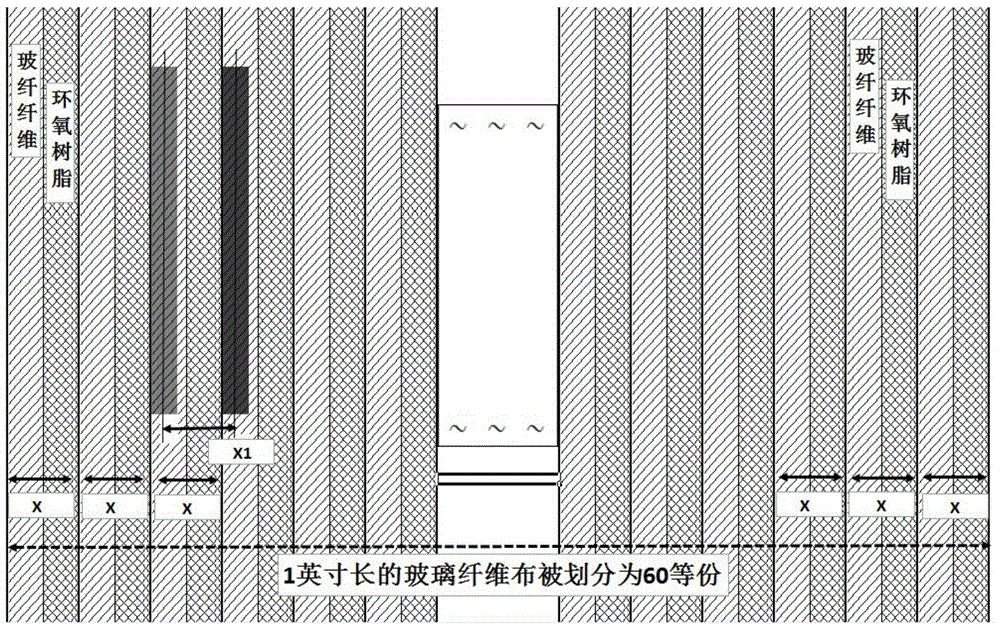

[0120] Step S02: According to the layout of the backplane, select the wiring direction that meets the requirements. If the warp direction is selected for wiring, then design the center distance of the differential line X1=X=1000 / m (mil), refer to image 3 ;

[0121] Step S03: According to the differential line center distance X1, under the premise of determining the differential impedance, follow the design method of using wi...

Embodiment 3

[0130] This embodiment provides a PCB board, comprising: a rectangular glass fiber cloth and a metal layer pasted on the surface of the glass fiber cloth by an adhesive; The adhesive between the glass fibers is formed; a differential signal line pair is formed on the metal layer, and the differential signal line pair extends along the dimension direction of the glass fiber cloth; direction, the glass fiber cloth includes a number of glass fiber units equal to the number of glass fiber strands, and the glass fiber unit includes: glass fibers in the dimension direction of the glass fibers and the binder

[0131] The line spacing between the differential signal lines and the line width of the differential signal lines are determined according to the width of the glass fiber unit;

[0132] The dimension direction of the glass fiber includes: the length or width direction of the glass fiber.

[0133] Preferably, the center-to-center distance between the differential signal line pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com