Polishing method for glass input window element and clamp

An input window and component technology, applied in grinding/polishing equipment, machine tools suitable for grinding workpiece planes, manufacturing tools, etc., can solve the problems of small size, input windows need to be reworked many times, and large and small surfaces removed. , to reduce the scrap rate and ensure the effect of anti-halation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

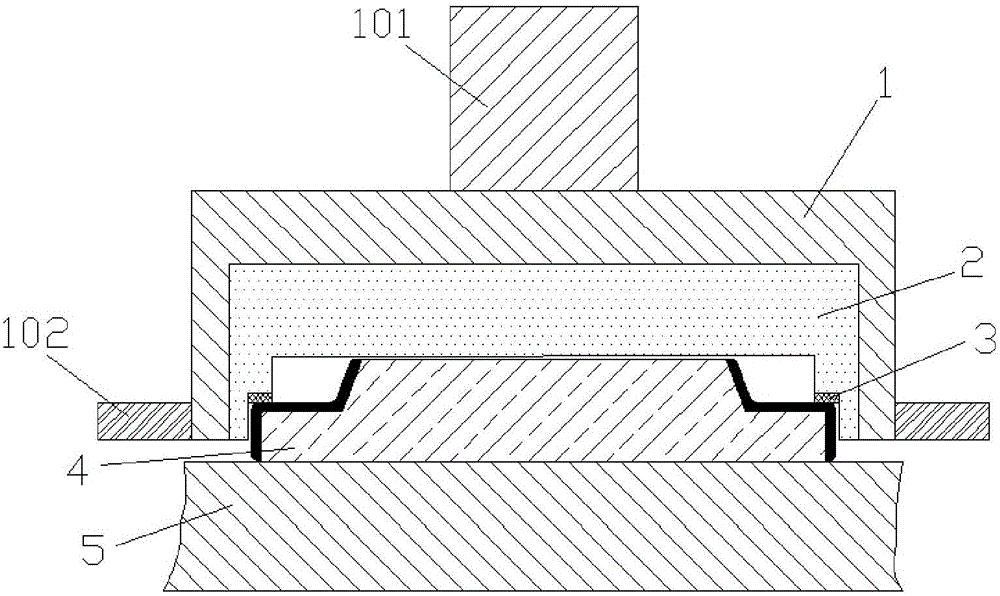

[0034] A method for polishing a glass input window element, wherein the two surfaces of the glass input window element are respectively subjected to preliminary polishing and final polishing, comprising the following steps:

[0035]The small surface of the input window processed by the production line is made of high borosilicate glass, with a diameter of ¢20mm, and the aperture is -13 with a flat flat crystal. It is observed with a 4X~10X magnifying glass under the light of a black background, and the surface is flawed.Ⅳ Grade, and the depth of scratches and pitting is relatively large. Therefore, it is determined that the anti-halation glass input window must be repaired in two steps of preliminary polishing and final polishing.

[0036] In the preliminary polishing and finishing, the method of manual polishing and finishing is adopted. The speed of the polishing disc is 30 rpm; the pressure is applied on the outside of the glass, and the pressure is less than 0.25 bar; the...

Embodiment 2

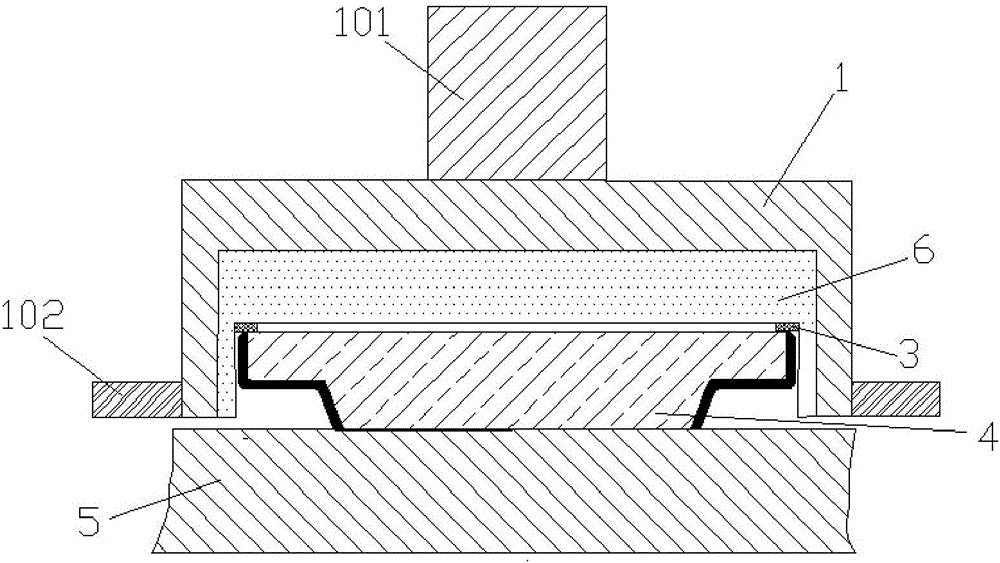

[0041] The quartz glass input window facet processed by the production line is made of quartz glass with a diameter of ¢20mm. The number of apertures N=-3 is measured with a flat flat crystal. Observed with a 4X~10X magnifying glass under the light of a black background, there are no surface defects. The disease is grade II, and the depth of scratches and pitting is very shallow. It was therefore determined that the anti-halation glass input window only needed to be reworked with a final polishing finish.

[0042] In the final polishing and finishing, cerium oxide polishing powder is selected, the particle size ranges from 1.5 to 3 microns, and it is disposable; the ratio of cerium oxide to distilled water in the polishing solution is 1:5 (mass ratio). The speed of the polishing disc is 1300 rpm, the pressure is applied on the outside of the glass, and the pressure is less than 0.25 bar; the pH value of the polishing solution is 5.5; the effective use time of the polishing sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com