Polishing method and jig for glass input window element

An input window and component technology, which is applied to grinding/polishing equipment, machine tools suitable for grinding workpiece planes, manufacturing tools, etc. and other problems to achieve the effect of reducing the scrap rate and ensuring the anti-halation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

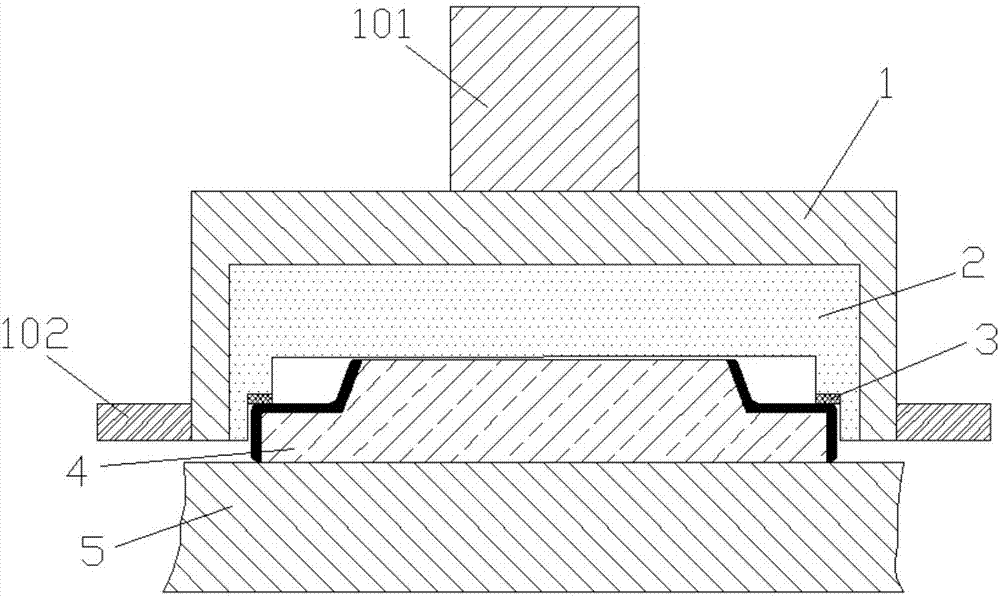

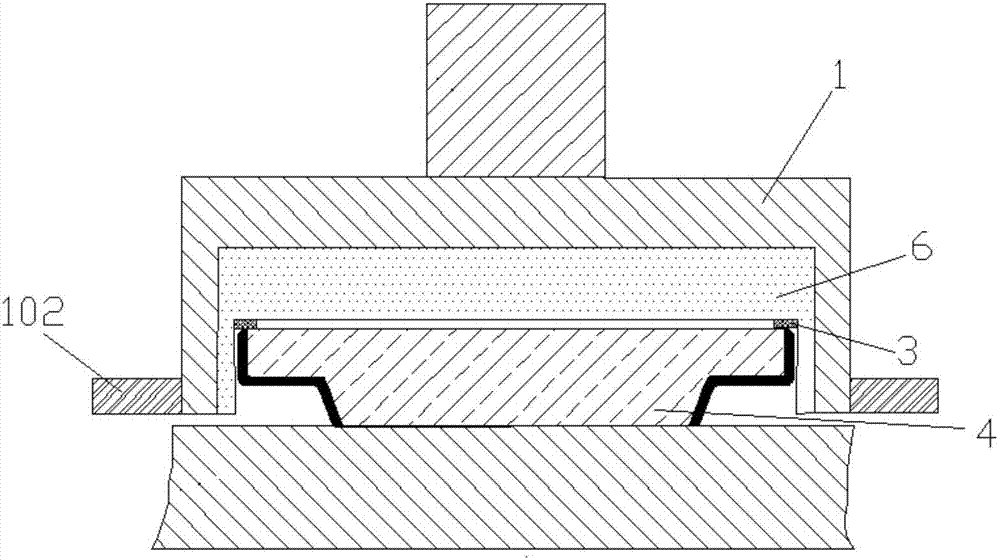

Image

Examples

Embodiment 1

[0034] A method for polishing a glass input window element, wherein the two surfaces of the glass input window element are respectively subjected to preliminary polishing and final polishing, comprising the following steps:

[0035]The small surface of the input window processed by the production line is made of high borosilicate glass, with a diameter of ¢20mm, and the aperture is -13 with a flat flat crystal. It is observed with a 4X~10X magnifying glass under the light of a black background, and the surface is flawed.Ⅳ Grade, and the depth of scratches and pitting is relatively large. Therefore, it is determined that the anti-halation glass input window must be repaired in two steps of preliminary polishing and final polishing.

[0036] In the preliminary polishing and finishing, the method of manual polishing and finishing is adopted. The speed of the polishing disc is 30 rpm; the pressure is applied on the outside of the glass, and the pressure is less than 0.25 bar; the...

Embodiment 2

[0041] The quartz glass input window facet processed by the production line is made of quartz glass with a diameter of ¢20mm. The number of apertures N=-3 is measured with a flat flat crystal. Observed with a 4X~10X magnifying glass under the light of a black background, there are no surface defects. The disease is grade II, and the depth of scratches and pitting is very shallow. It was therefore determined that the anti-halation glass input window only needed to be reworked with a final polishing finish.

[0042] In the final polishing and finishing, cerium oxide polishing powder is selected, the particle size ranges from 1.5 to 3 microns, and it is disposable; the ratio of cerium oxide to distilled water in the polishing solution is 1:5 (mass ratio). The speed of the polishing disc is 1300 rpm, the pressure is applied on the outside of the glass, and the pressure is less than 0.25 bar; the pH value of the polishing solution is 5.5; the effective use time of the polishing sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com