Flame-retardant, thermal-insulation and sound-absorption material structure for aircraft fuselage bottom

A technology of sound-absorbing materials and aircraft fuselage, applied in the direction of fuselage, fuselage insulation, aircraft parts, etc., can solve problems such as oil leakage and fire, and achieve the effects of improved flame retardancy, simple and practical flame-retardant methods, and low bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

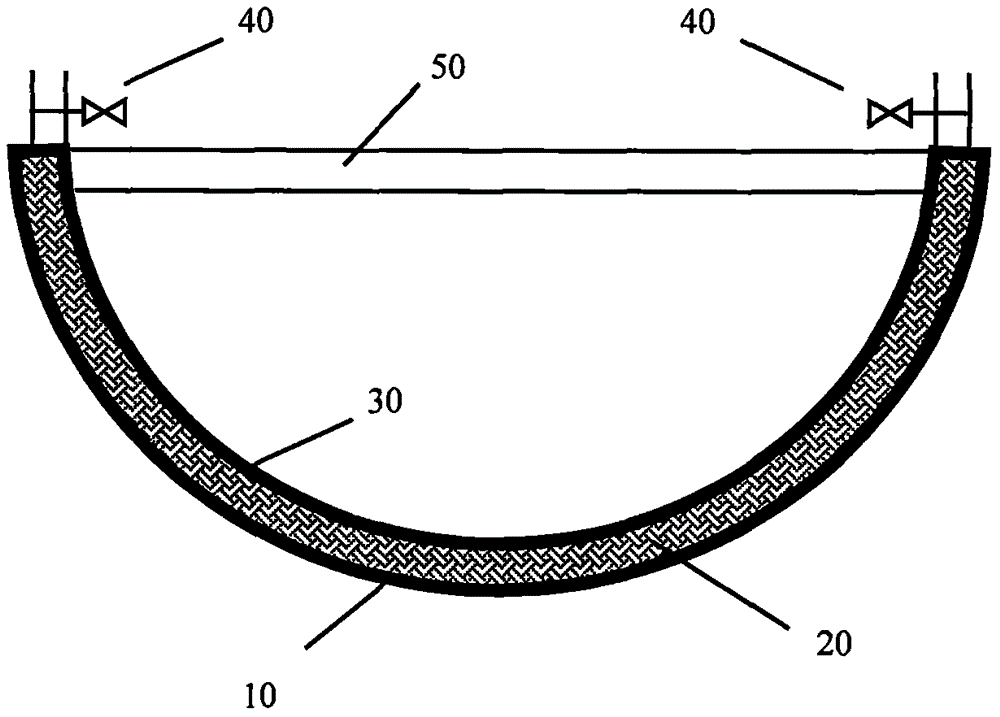

[0018] A flame-retardant, heat-insulating and sound-absorbing material structure for the bottom of an aircraft fuselage is characterized in that it is composed of an outer shell, foam, inner shell and inner bottom plate of the fuselage in sequence from the outside to the inside; the outer shell is made of carbon fiber or glass fiber and resin glue. Molecular composite material, the foam is open-cell foam, the porosity is 95%, and the bulk density is 6Kg / m 3 , the composition is melamine, the thickness is 10mm, and the inner shell is carbon fiber reinforced plastic; the foam is placed in the cavity between the outer shell and the inner shell, and there is a water valve at the top of both sides of the cavity, and the distance between the water valves is 1m. It is connected with the water storage tank on the aircraft, the water valve is an electric switch, and the switch connection line is located in the front cabin and the rear cabin of the aircraft.

[0019] The polymer resin i...

Embodiment 2

[0024] A flame-retardant, heat-insulating and sound-absorbing material structure for the bottom of an aircraft fuselage is characterized in that it is composed of an outer shell, foam, inner shell and inner bottom plate of the fuselage in sequence from the outside to the inside; the outer shell is made of carbon fiber or glass fiber and resin glue. Molecular composite material, the foam is open-cell foam, the porosity is 99%, and the bulk density is 15Kg / m 3 , the composition is melamine, the thickness is 200mm, and the inner shell is carbon fiber reinforced plastic; the foam is placed in the cavity between the outer shell and the inner shell, and there is a water valve at the top of both sides of the cavity, and the distance between the water valves is 5m. It is connected with the water storage tank on the aircraft, the water valve is an electric switch, and the switch connection line is located in the front cabin and the rear cabin of the aircraft.

[0025] The polymer resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com