Mixed chamber mode locking laser oscillator and laser outputting method thereof

A mode-locked laser and hybrid cavity technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of complex structure, large volume, and unguaranteed beam quality of the output system, so as to avoid damage and improve the output. The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

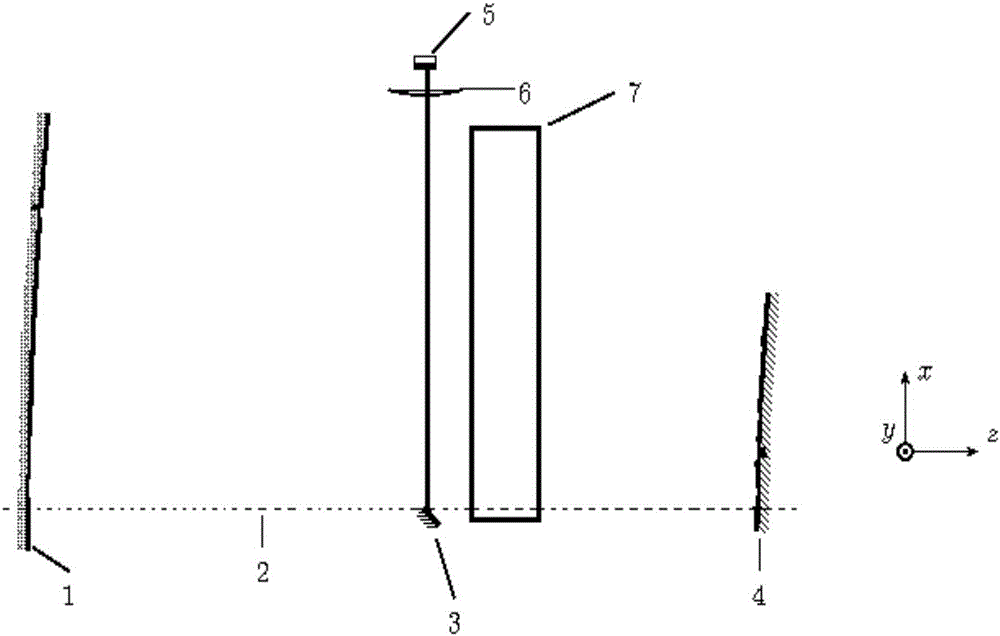

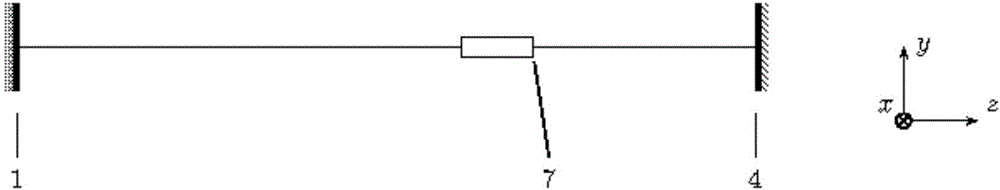

[0036] Concave cylindrical reflector 2: R1 = 250mm, width 20mm, height 10mm, convex cylindrical reflector 4: R2 = 125mm, width 6mm, height 10mm, and the end close to the center line of laser crystal 7 should be ground with a knife edge, concave Cylindrical reflector 1 and convex cylindrical reflector 4 are placed at a distance of 60mm, laser crystal 7 is Nd:YVO4 of 14mmx1mmx10mm (corresponding to the three directions of x, y, and z respectively), and the distance to the left of laser crystal 7 from concave cylindrical reflector 1 is Placed at 35mm, the plane reflector 3 is placed at an angle of 45 degrees to the optical axis, the matching lens 6 is a convex lens with a focal length of 60mm, the semiconductor saturable absorption mirror 5 is a 3mmX3mm semiconductor saturable absorption mirror 5 with a dominant wavelength of 1064nm from BATOP Company, and the pump light source is selected 880nm wavelength laser diode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com