Method for preparing aluminum hydroxide sulfate

An aluminum sulfate, basic technology, applied in the direction of aluminum sulfur compounds, etc., can solve the problems of complex production operations, long reaction time, calcium sulfate production, etc., and achieve the effects of easy large-scale production, easy operation, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

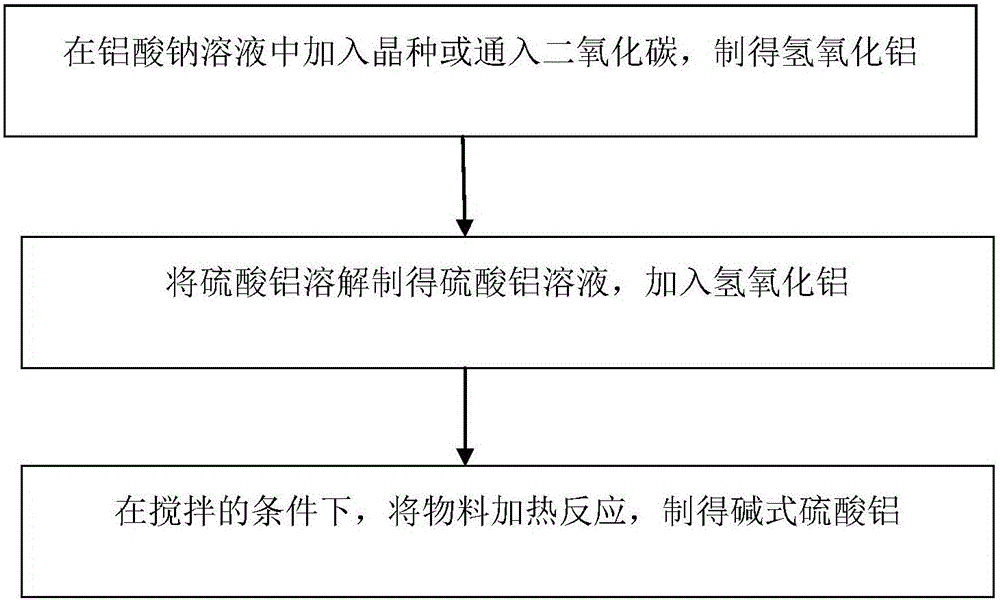

Method used

Image

Examples

Embodiment 1

[0025] Take 100g of aluminum sulfate, add 50g of water and heat to dissolve, make aluminum sulfate solution and put it in the reaction kettle. Then add 2 g of aluminum hydroxide, heat the material to 90° C., keep the reaction temperature at 90° C. under stirring, and react for 60 minutes to obtain basic aluminum sulfate solution. The basic aluminum sulfate chemical formula ([Al 2 (OH) n (SO 4 ) 3-n / 2 ] m ) of n is 0.462. (m indicates that basic aluminum sulfate is a polymer, and m is a positive integer <10)

Embodiment 2

[0027] Take 100g of aluminum sulfate, add 50g of water and heat to dissolve, make aluminum sulfate solution and put it in the reaction kettle. Then add 5 g of aluminum hydroxide, heat the material to 150° C., keep the reaction temperature at 150° C. under stirring, and react for 100 minutes to obtain basic aluminum sulfate solution. The basic aluminum sulfate chemical formula ([Al 2 (OH) n (SO 4 ) 3-n / 2 ] m ) of n is 1.055.

Embodiment 3

[0029] Take 100g of aluminum sulfate, add 50g of water and heat to dissolve, make aluminum sulfate solution and put it in the reaction kettle. Then add 10 g of aluminum hydroxide, heat the material to 250° C., keep the reaction temperature at 250° C. under stirring, and react for 5 minutes to obtain basic aluminum sulfate solution. The basic aluminum sulfate chemical formula ([Al 2 (OH) n (SO 4 ) 3-n / 2 ] m ) of n is 1.795.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com