Calcium vanadate microsphere material and its preparation method and application

A technology of microspheres and calcium vanadate, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., to achieve the effects of strong ultraviolet-visible light absorption, rich material fields, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

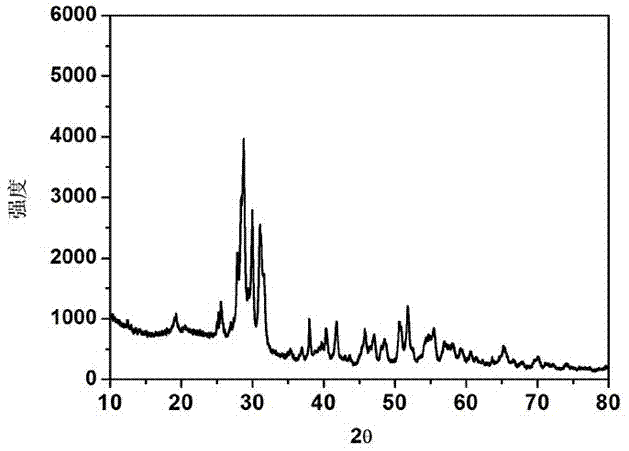

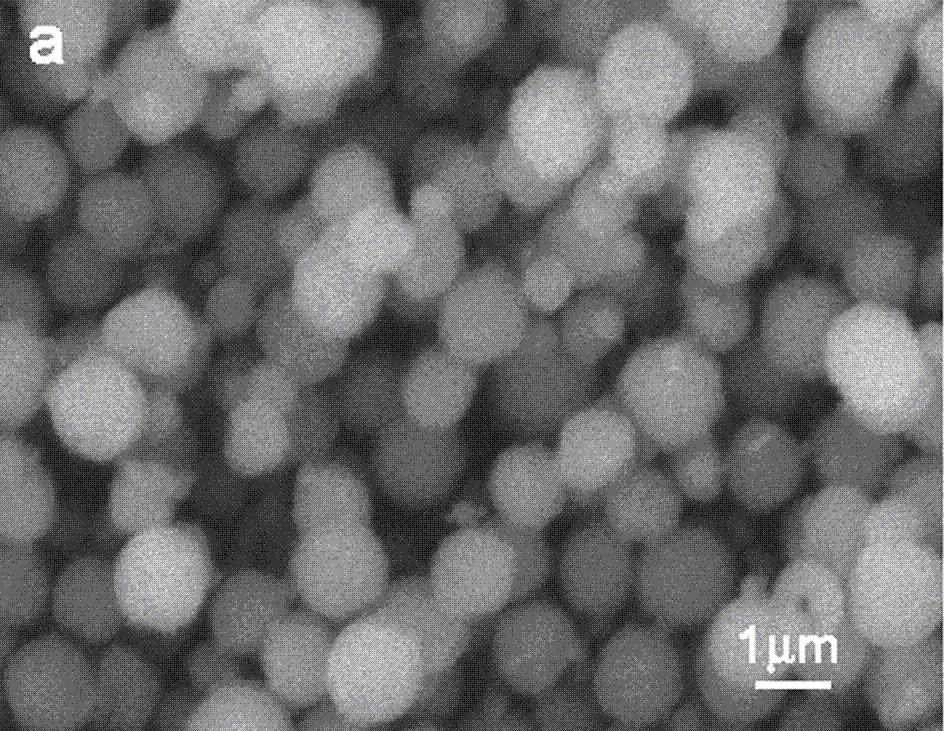

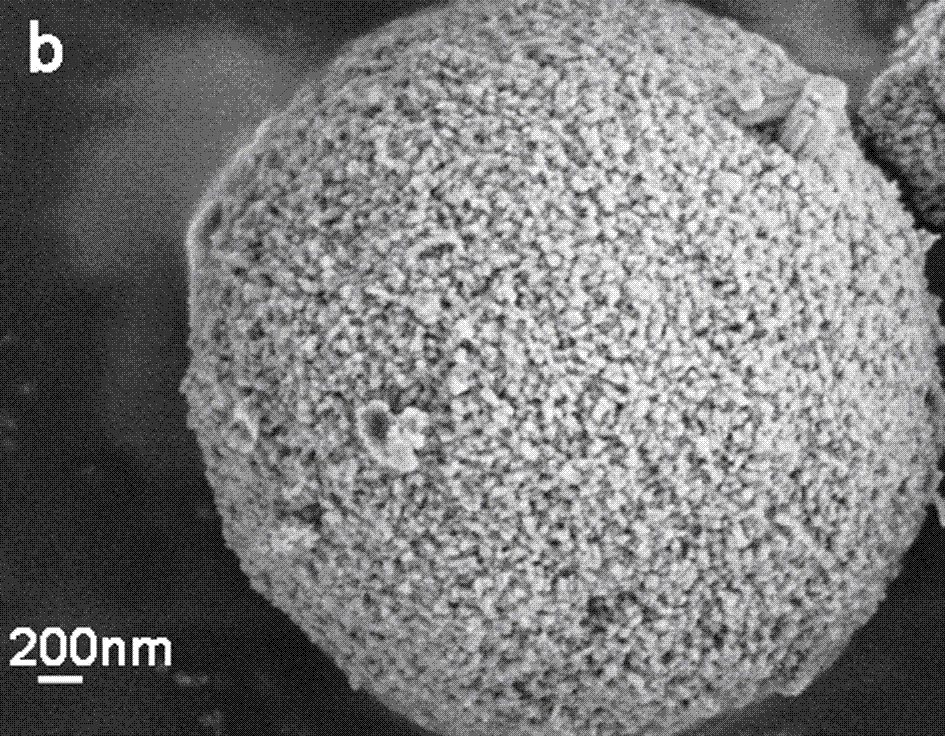

[0027] At room temperature, 2 mmol of sodium orthovanadate was dissolved in 10 mL of distilled water, and 1 mmol of CaCl 2 Dissolved in 8mL distilled water, under magnetic stirring, the sodium orthovanadate solution was added dropwise to the CaCl 2 solution, stirred for 10 min, with 1mol / L HNO 3 The solution adjusted the pH value of the reaction system to 10, continued to stir for 10 min, then transferred it into a 25 mL hydrothermal reaction kettle, sealed it and placed it in a constant temperature box for 12 hours of hydrothermal reaction at 180 °C, and cooled to room temperature after the reaction , were centrifuged and washed 5 times with deionized water and absolute ethanol, and the resulting precipitate was dried in an oven at 80 °C for 8 hours to obtain Ca 2 V 2 o 7 microsphere material. The above product was subjected to X-ray diffraction (XRD) analysis, figure 1 It is an XRD spectrum, and the result shows that the product diffraction peak is related to Ca 2 V 2...

Embodiment 2

[0029] At room temperature, 2 mmol of sodium orthovanadate was dissolved in 7 mL of distilled water, and 1 mmol of CaCl 2 Dissolve in 9mL distilled water, and add sodium orthovanadate solution dropwise to CaCl under magnetic stirring 2 solution, stirred for 10 min, with 1mol / L HNO 3 The solution adjusts the pH value of the reaction system to 9 and continues to stir for 10 min, then transfers it into a 20 mL hydrothermal reaction kettle, seals it, and places it in a thermostat for 6 hours of hydrothermal reaction at 160 °C, and cools to room temperature after the reaction is completed , were centrifuged and washed five times with deionized water and absolute ethanol, and then dried in an oven at 80 °C for 12 hours to obtain Ca 2 V 2 o 7 microsphere material. XRD spectrum ( image 3 ) results show that the product diffraction peaks are closely related to Ca 2 V 2 o 7 match. SEM analysis was performed at a higher magnification ( Figure 4 ) indicates that the product ha...

Embodiment 3

[0031] At room temperature, 1 mmol of sodium orthovanadate was dissolved in 7 mL of distilled water, and 1 mmol of CaCl 2 Dissolved in 7mL of distilled water, under the action of magnetic stirring, the sodium orthovanadate solution was added dropwise to the CaCl 2 solution, stirred for 10 min, with 1mol / L HNO 3 The solution adjusted the pH value of the reaction system to 10 and continued to stir for 10 min, then transferred it into a 20 mL hydrothermal reaction kettle, sealed it, and placed it in a thermostat for 48 h at 160 °C for hydrothermal reaction. After the reaction was completed, it was cooled to At room temperature, the obtained precipitate was washed 6 times with deionized water and then washed 5 times with absolute ethanol, and then the obtained precipitate was placed in an oven at 80 °C for 8 h in vacuum to obtain Ca 2 V 2 o 7 microsphere material. SEM analysis ( Figure 5 ) indicates that the diameter of the microsphere is 0.5-1.0 μm, and the surface of each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com