Basic cobalt vanadate microsheet material and preparation method thereof

A technology of cobalt vanadate and micro flakes is applied in nanotechnology, nanotechnology, nanotechnology and other directions for material and surface science to achieve the effects of mild reaction conditions, suitable for mass production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] At room temperature, respectively dissolve 2 mmol of ammonium metavanadate into 8 mL of distilled water, and dissolve 1 mmol of cobalt acetate into 8 mL of distilled water, and add the ammonium metavanadate solution dropwise to the cobalt acetate solution under magnetic stirring After the dropwise addition, continue to stir for 10 min, then transfer it to a 25 mL hydrothermal reaction kettle, seal it, place it in a constant temperature box, and conduct a hydrothermal reaction at 180 °C for 6 hours, cool to room temperature after the reaction, and use a deionized Water and absolute ethanol were centrifuged and washed 5 times, and the obtained precipitate was dried in an oven at 80°C for 8 hours to obtain the product.

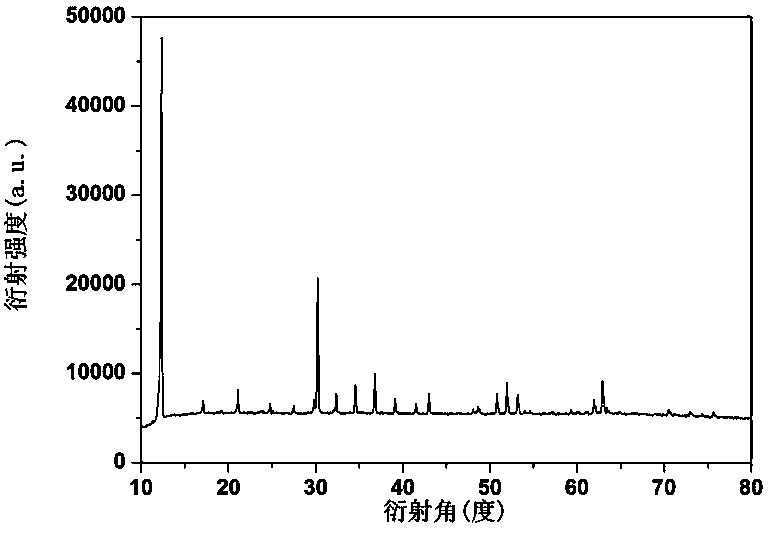

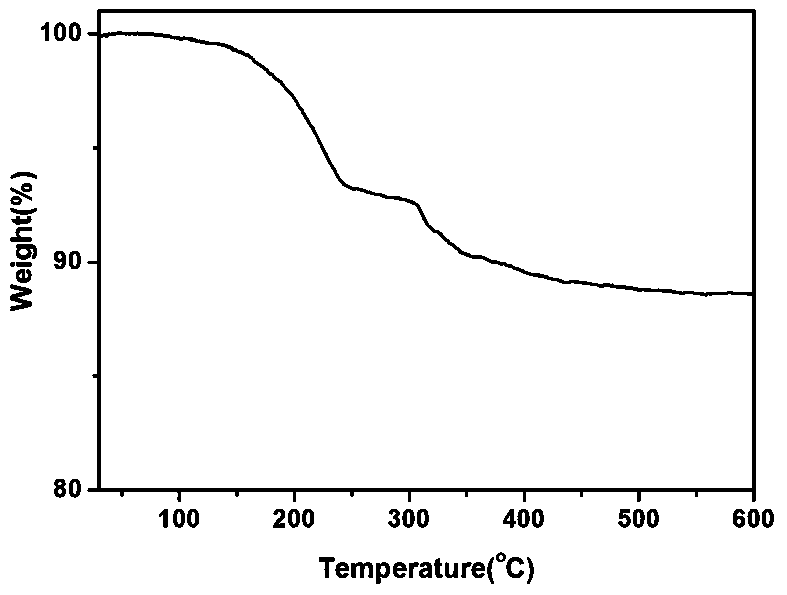

[0028] The above product was subjected to X-ray diffraction (XRD) analysis, figure 1 is the XRD spectrum. The diffraction peaks of the product do not match the substances containing Co, V, O, and H in the existing JCPDS-ICDD database, but the intensity an...

Embodiment 2

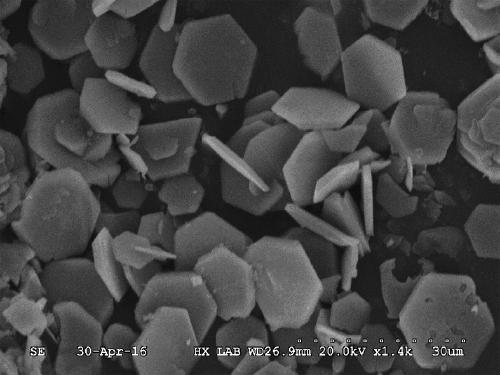

[0030]At room temperature, dissolve 1.8 mmol of ammonium metavanadate in 14 mL of distilled water, dissolve 1 mmol of cobalt acetate in 2 mL of distilled water, and add the ammonium metavanadate solution dropwise to the cobalt acetate solution under magnetic stirring. Stir for 10 min, then transfer to a 20 mL hydrothermal reaction kettle, seal it and place it in a thermostat for 12 hours at 180 °C for hydrothermal reaction, cool to room temperature after the reaction, and centrifuge with deionized water and absolute ethanol, respectively After washing 5 times, place in an oven and dry at 80°C for 12 hours to obtain basic cobalt vanadate microsheet material. The above product was subjected to X-ray diffraction (XRD) analysis, Figure 5 Be XRD spectrum figure, its XRD spectrum is identical with embodiment 1, based on the same analysis of embodiment 1, its product is Co 3 (OH) 2 V 2 o 7 2H 2 O. Figure 6 It is a scanning electron microscope analysis picture, which shows tha...

Embodiment 3

[0032] At room temperature, dissolve 1 mmol of ammonium metavanadate in 14 mL of distilled water, dissolve 0.5 mmol of cobalt acetate in 2 mL of distilled water, and add the ammonium metavanadate solution dropwise to the cobalt acetate solution under magnetic stirring , continue to stir for 10 min after the dropwise addition, then transfer it into a 20 mL hydrothermal reaction kettle, seal it and place it in a constant temperature box for a hydrothermal reaction at 160 °C for 6 hours, cool to room temperature after the reaction, and use deionized water and Absolute ethanol was centrifuged and washed 5 times, and the obtained precipitate was dried in an oven at 80°C for 8 hours to obtain basic cobalt vanadate microsheet materials. The above product was subjected to X-ray diffraction (XRD) analysis, Figure 7 Be XRD spectrum figure, its XRD spectrum is identical with embodiment 1, based on the same analysis of embodiment 1, its product is Co 3 (OH) 2 V 2 o 7 2H 2 O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com