Offset ink and preparation method thereof

A technology of offset printing ink and linseed oil, which is applied in the field of offset printing, can solve the problems of insufficient dispersion of anti-wear agent, poor anti-wear performance of offset printing ink, and easy detachment, so as to enhance bonding force, increase anti-wear performance, and improve anti-wear performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

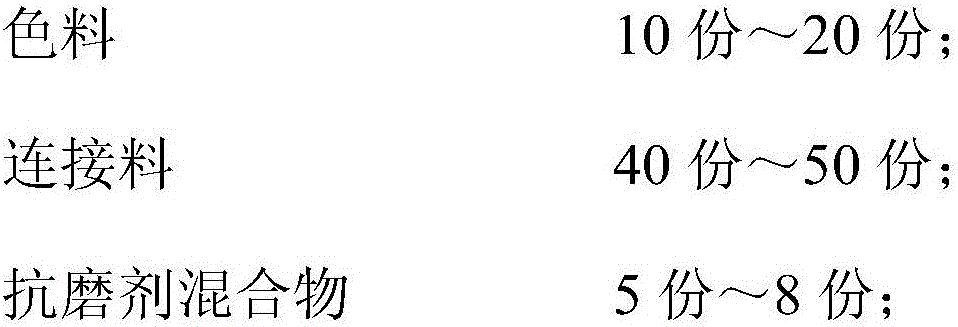

[0046] The magenta ink described in the present embodiment, its component is:

[0047]

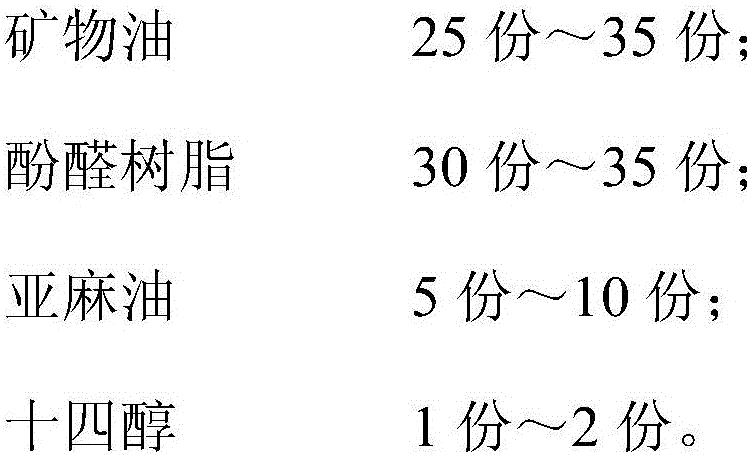

[0048] Described connecting material, its component and each component weight portion are:

[0049]

[0050] The antiwear mixture is composed of the following components in parts by weight:

[0051] 30 parts of resin oil;

[0052] Silane coupling agent is KH55045 parts;

[0053] The anti-wear agent is 4 parts of micro wax powder.

[0054] Described wax paste is made up of the component of following parts by weight:

[0055] 3 parts linseed oil;

[0056] 55 parts of mineral oil;

[0057] 15 parts beeswax.

[0058] The concrete preparation steps of described offset printing ink are:

[0059] S1. According to the selected parts by weight of resin oil and silane coupling agent KH550, put them in the reactor and stir evenly, and heat to 150°C for heat preservation treatment, then add the selected parts by weight of anti-wear agent into the reactor Microwax powder and stir evenly t...

Embodiment 2

[0065] The middle yellow ink described in the present embodiment, its component is:

[0066] The color material is GO-1 yellow and 1151G orange base ink, among which, GO-1 yellow is 18kg, and 1151G orange base ink is 1.5kg

[0067]

[0068]

[0069] Described connecting material, its component and each component weight portion are:

[0070]

[0071] The antiwear mixture is composed of the following components in parts by weight:

[0072] 20 parts of resin oil;

[0073] Silane coupling agent is KH56035 parts;

[0074] The anti-wear agent is 3 parts of micro wax powder.

[0075] Described wax paste is made up of the component of following parts by weight:

[0076] 6 parts linseed oil;

[0077] 60 parts of mineral oil;

[0078] 12 parts beeswax.

[0079] The concrete preparation steps of described offset printing ink are:

[0080] S1. According to the selected parts by weight of resin oil and silane coupling agent KH560, put them in the reactor and stir evenly, a...

Embodiment 3

[0086] The sky blue printing ink described in the present embodiment, its component is:

[0087]

[0088] Described connecting material, its component and each component weight portion are:

[0089]

[0090] The antiwear mixture is composed of the following components in parts by weight:

[0091] 25 parts of resin oil;

[0092] The silane coupling agent is KH56037 parts;

[0093] The antiwear agent is 3.5 parts of micro wax powder.

[0094] Described wax paste is made up of the component of following parts by weight:

[0095] 4 parts linseed oil;

[0096] 50 parts of mineral oil;

[0097] 14 parts beeswax.

[0098] The concrete preparation steps of described offset printing ink are:

[0099] S1. According to the selected parts by weight of resin oil and silane coupling agent KH560, put them in the reactor and stir evenly, and heat them to 170°C for heat preservation treatment, and then add the selected parts by weight of anti-wear agent into the reactor Microwax ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com