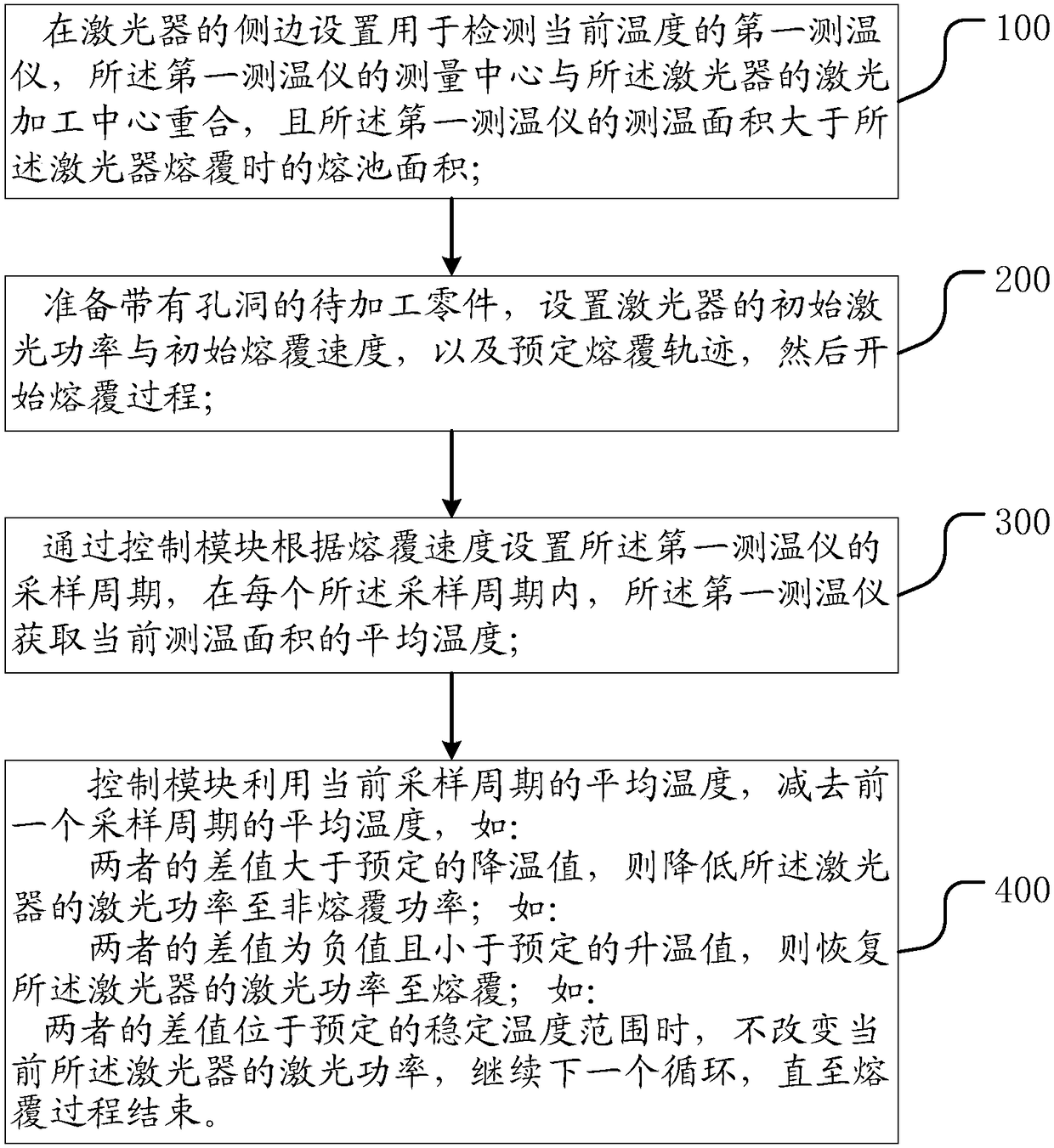

Closed-loop control method of laser cladding

A closed-loop control, laser cladding technology, applied in the direction of metal material coating process, coating, etc., can solve the problems affecting the quality of the cladding layer, increasing the cost and complexity of laser cladding, collapse, etc., to avoid high temperature collapse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

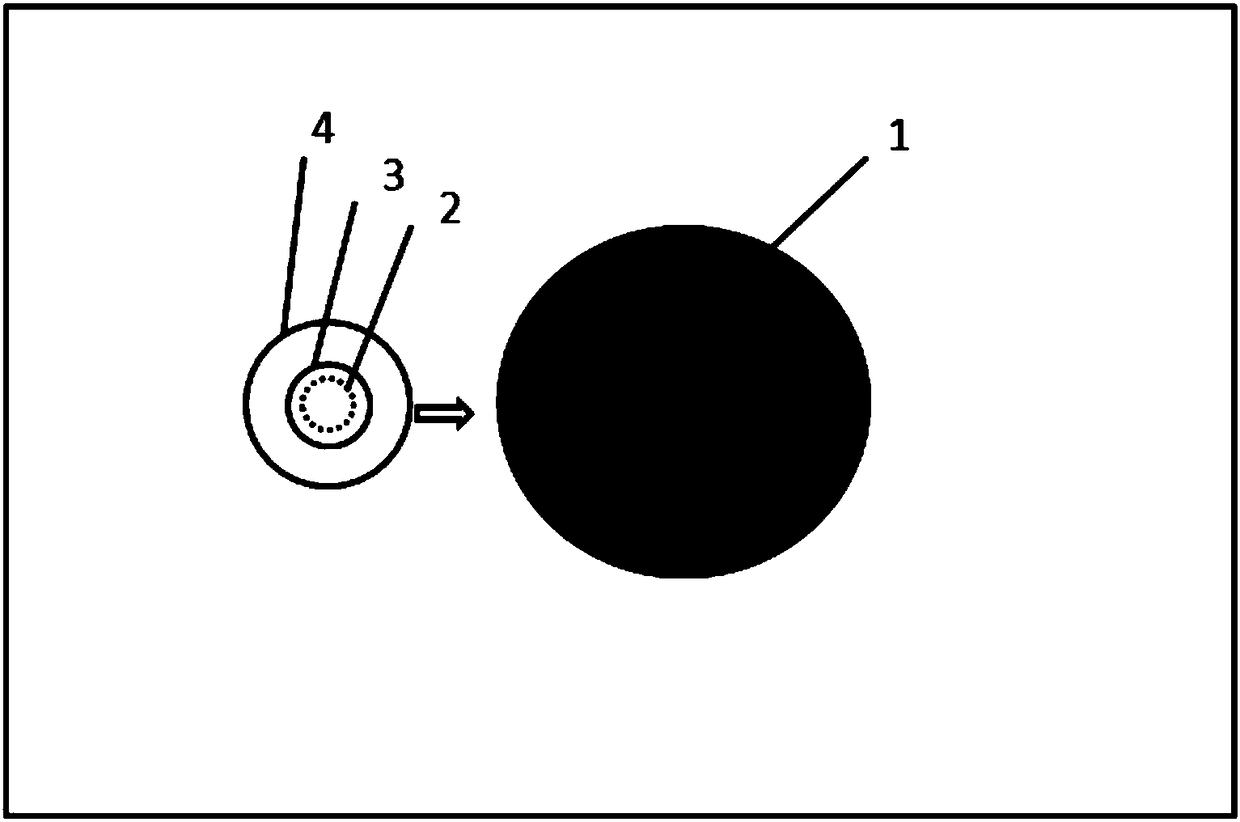

[0057] Let the diameter of the first temperature measuring area of the first thermometer be D 1 , the diameter of the second temperature measuring area of the second thermometer is D 2 , the first average temperature obtained by the first thermometer in the current acquisition cycle is T i , the first average temperature obtained in the previous acquisition cycle is T i-1 , the second average temperature obtained by the second thermometer in the current acquisition cycle is T n , the second average temperature obtained in the previous acquisition cycle is T n-1 , the initial laser power at the beginning of laser cladding is P, the initial cladding speed is V, and the cladding trajectory is not limited.

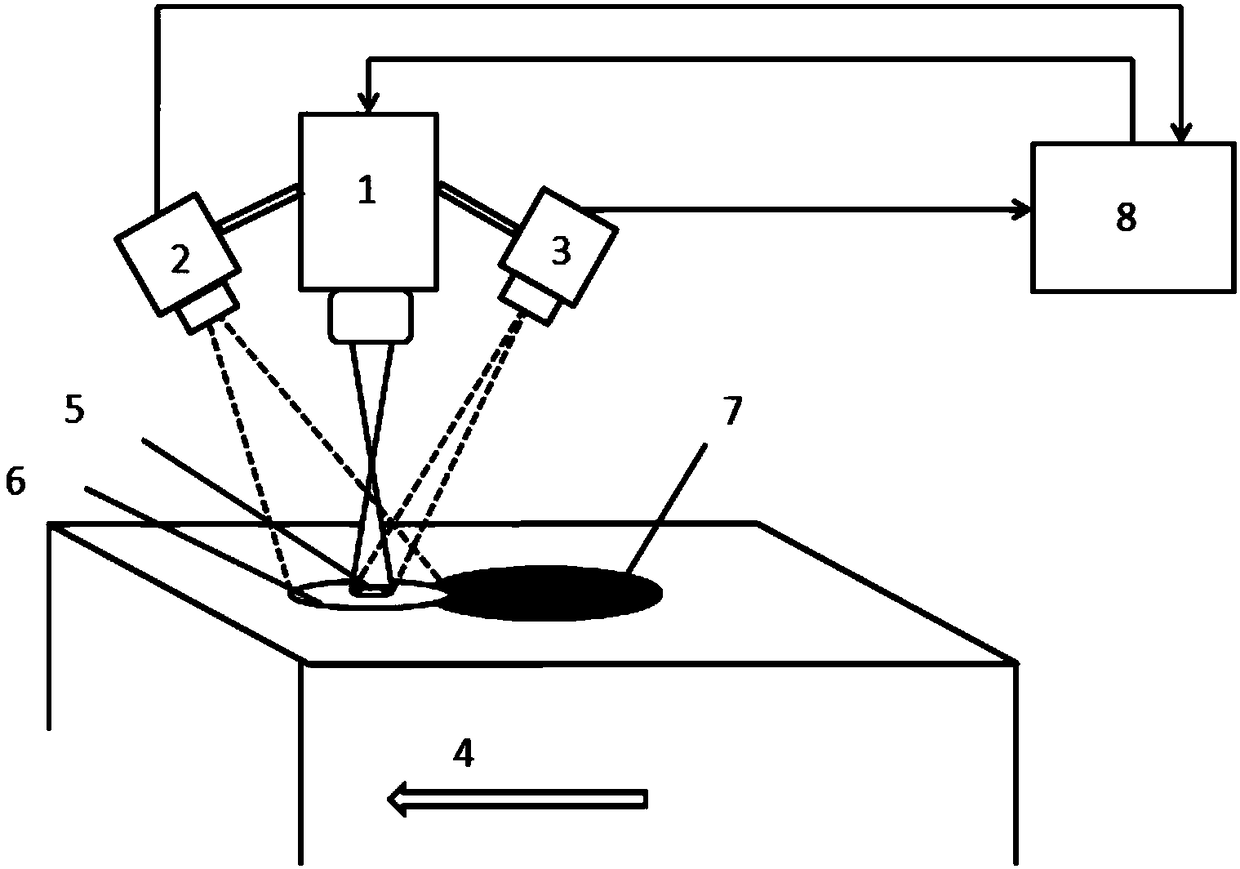

[0058] Such as figure 2 As shown, the cladding equipment involved in the embodiment of the present invention includes: a laser, a first temperature measuring instrument, a second temperature measuring instrument and a control device; wherein, the laser emitted by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com