Electro-deposition clamp

A technology of electrodeposition and fixtures, which is applied in the electrolysis process and electrolysis components, etc., can solve the problems of not very firm connection, affecting the coating effect, and cumbersome fixing of the plate, so as to save manpower, have a simple and reasonable structure, and improve the efficiency of electrodeposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

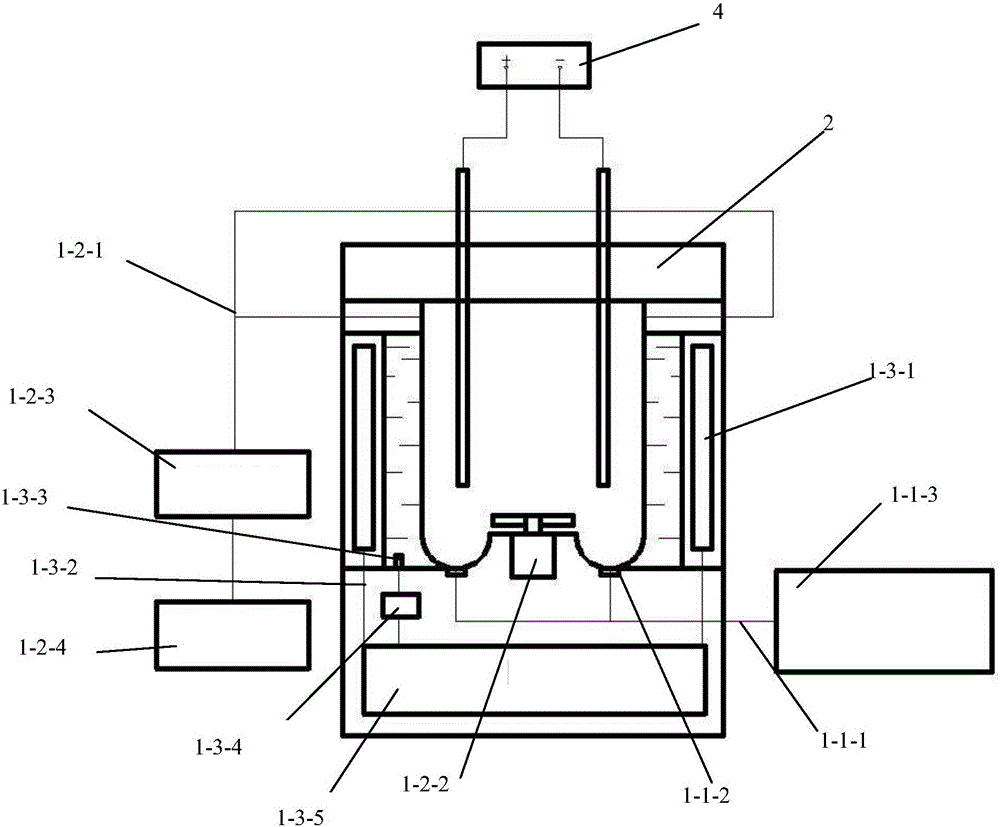

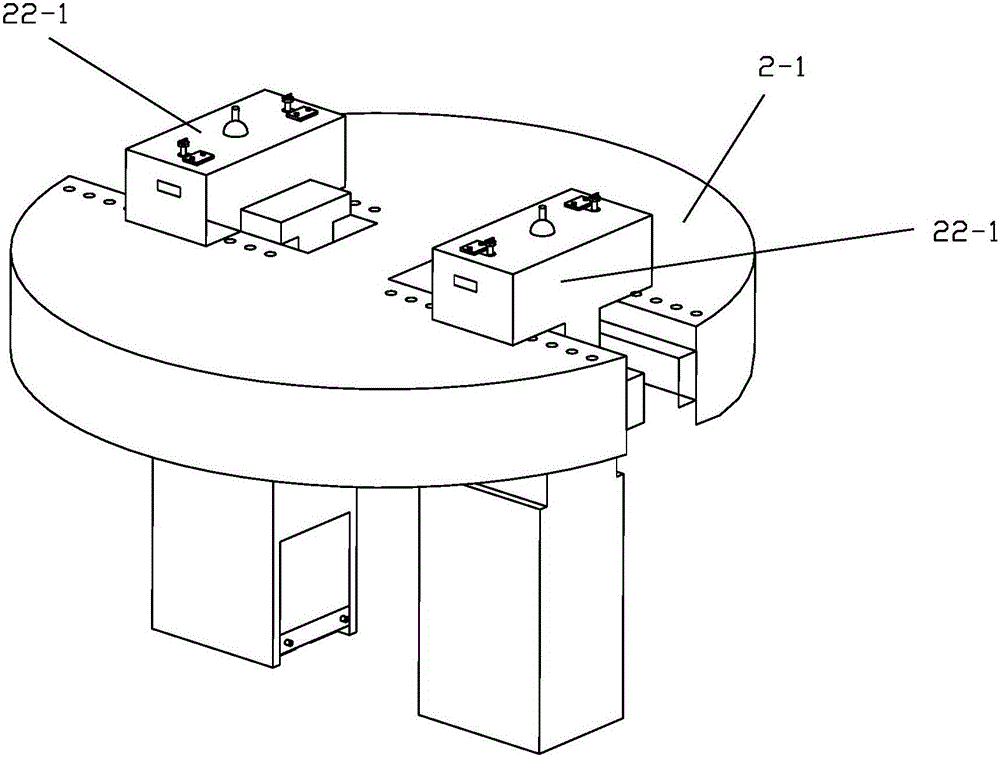

[0050] like Figure 1-9 As shown, a kind of electrodeposition fixture 2, it comprises:

[0051] Bracket 2-1;

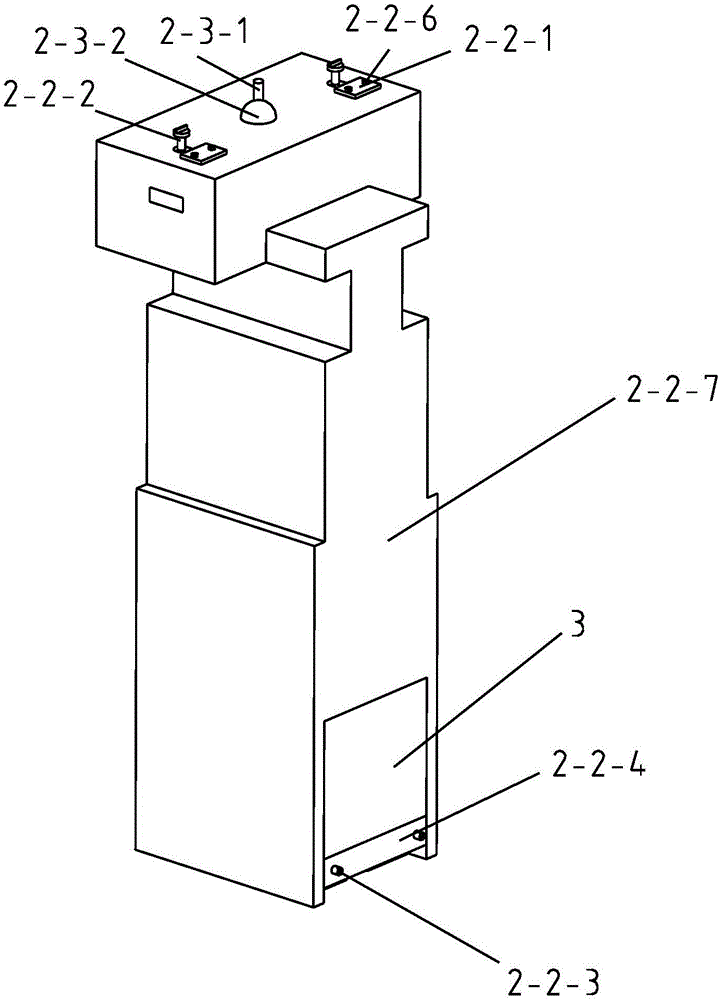

[0052] At least one set of electrode clamping groups, each electrode clamping group includes two electrode clamping assemblies, the corresponding electrode clamping assemblies are used to carry the corresponding electrode plates 3, and the electrode clamping assemblies each have sliders 2-2- 7, and the electrode clamping components are all slipped on the bracket 2-1, so that in the same group of electrode clamping groups, when sliding any one or both of the electrode clamping components relative to the bracket 2-1, the two The distance between the electrode plates 3 carried on the electrode clamping assembly becomes larger or smaller; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com