Fluid fuel quantitative mixing device for vehicle engine

A vehicle engine and liquid fuel technology, applied to fuel injection devices, engine components, machines/engines, etc., can solve problems such as unstable fuel supply pressure and uneven mixing, and achieve simple structure, easy fuel replacement, and satisfactory combustion the effect of the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

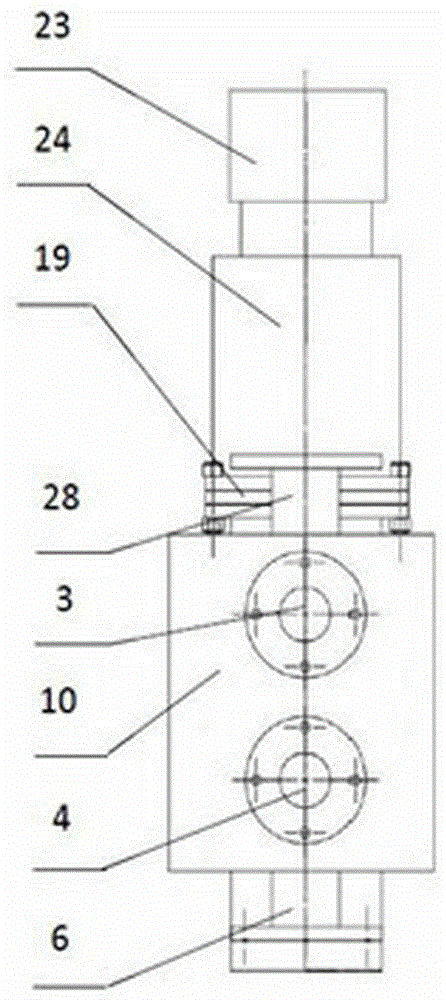

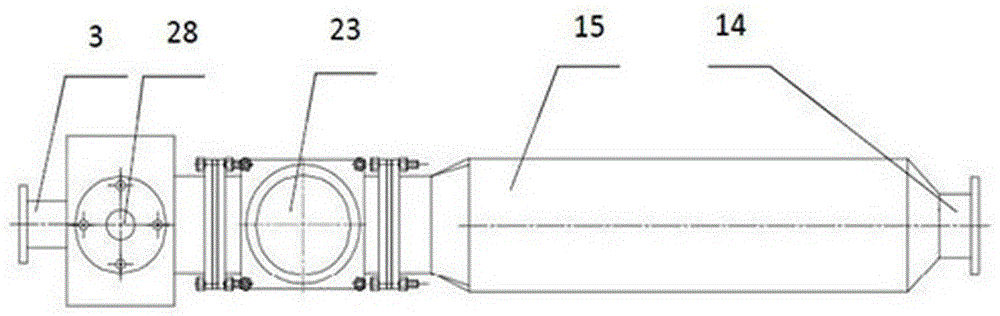

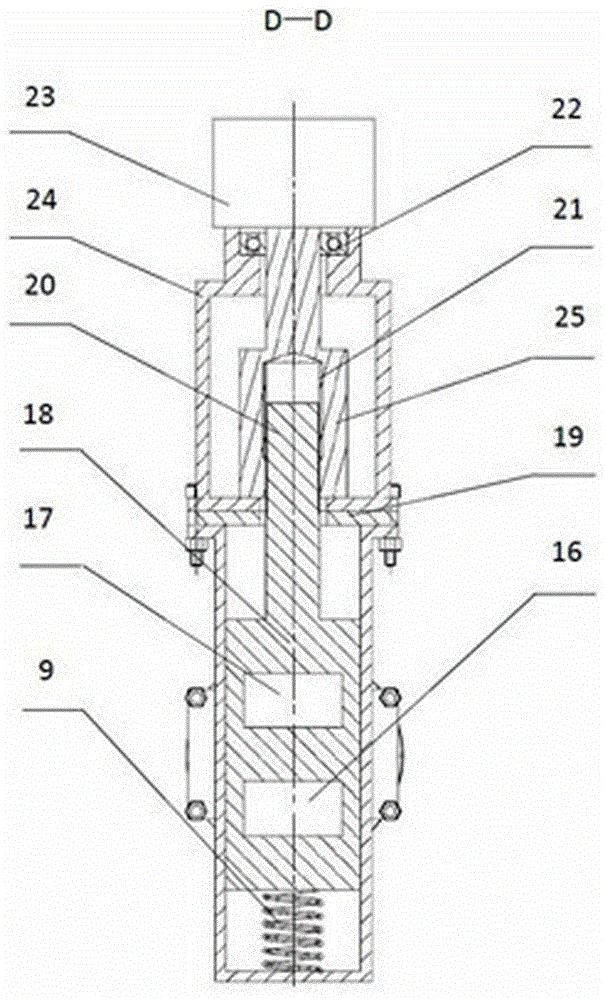

[0025] Example 1 as Figure 1-4 As shown, a liquid fuel quantitative mixing device for a vehicle engine includes a pressure regulating valve A, a distributor B and a mixer C connected sequentially by bolts and sealing gaskets;

[0026] The middle part of the pressure regulating valve housing 5 of the pressure regulating valve A is a pressure regulating valve chamber, the first oil return pipe 6 of the pressure regulating valve and the second oil return pipe 28 of the pressure regulating valve are straight pipes with a bell mouth at one end, and the horn There is a gap between the ports and it is relatively placed in the middle of the pressure regulating valve chamber. The straight pipes protrude from the middle of the upper and lower ends of the pressure regulating valve chamber respectively, and are sealed with the pressure regulating valve chamber. The tanks of the two fuels are connected;

[0027] The pressure diaphragm 2 is placed in the gap between the first oil return p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com