Hydrostatic drives for slewing mechanisms, slewing mechanisms with such devices

A technology of driving device and slewing mechanism, which is applied in the direction of fluid pressure actuating device, accumulator device, earth mover/shovel, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

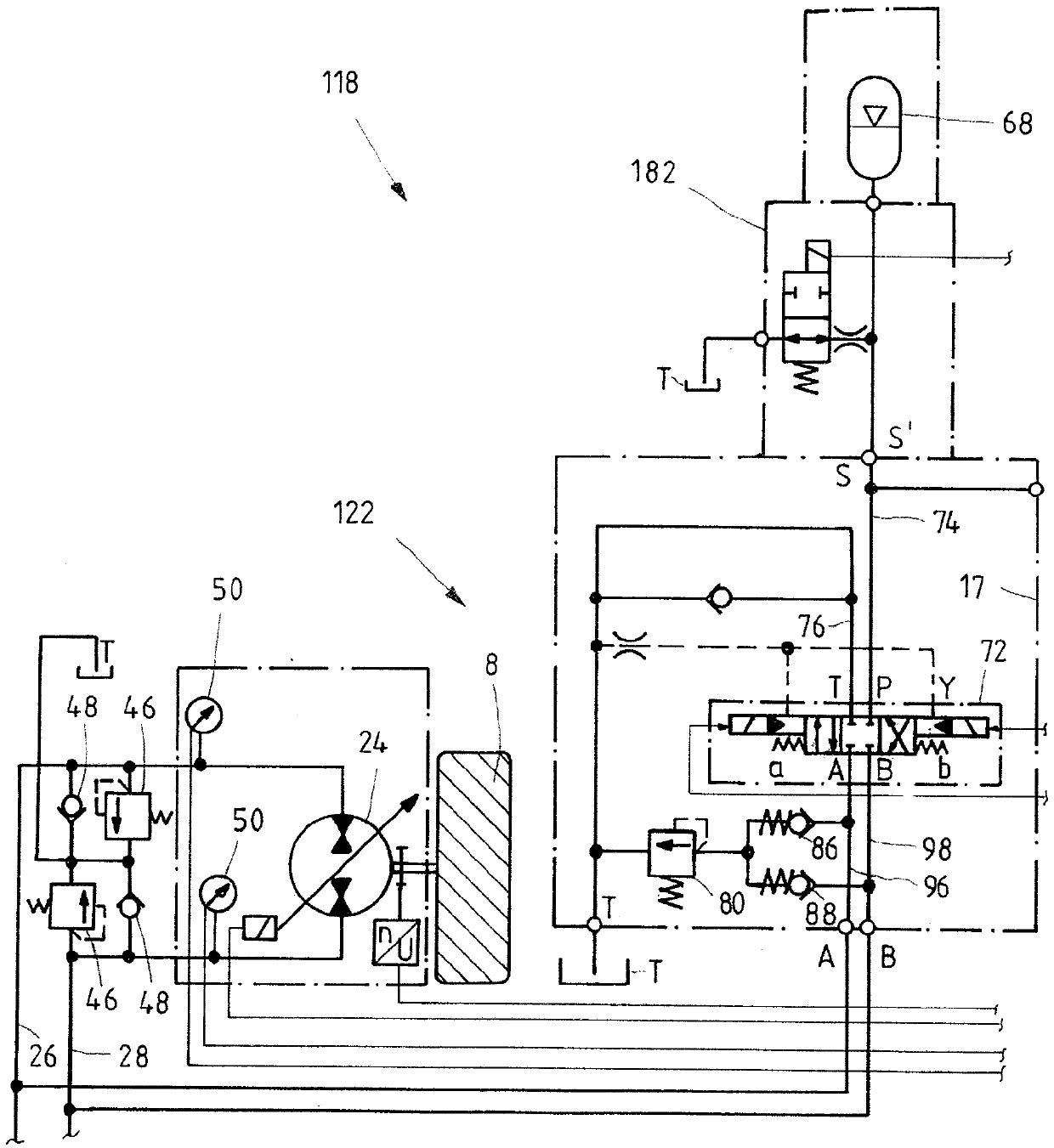

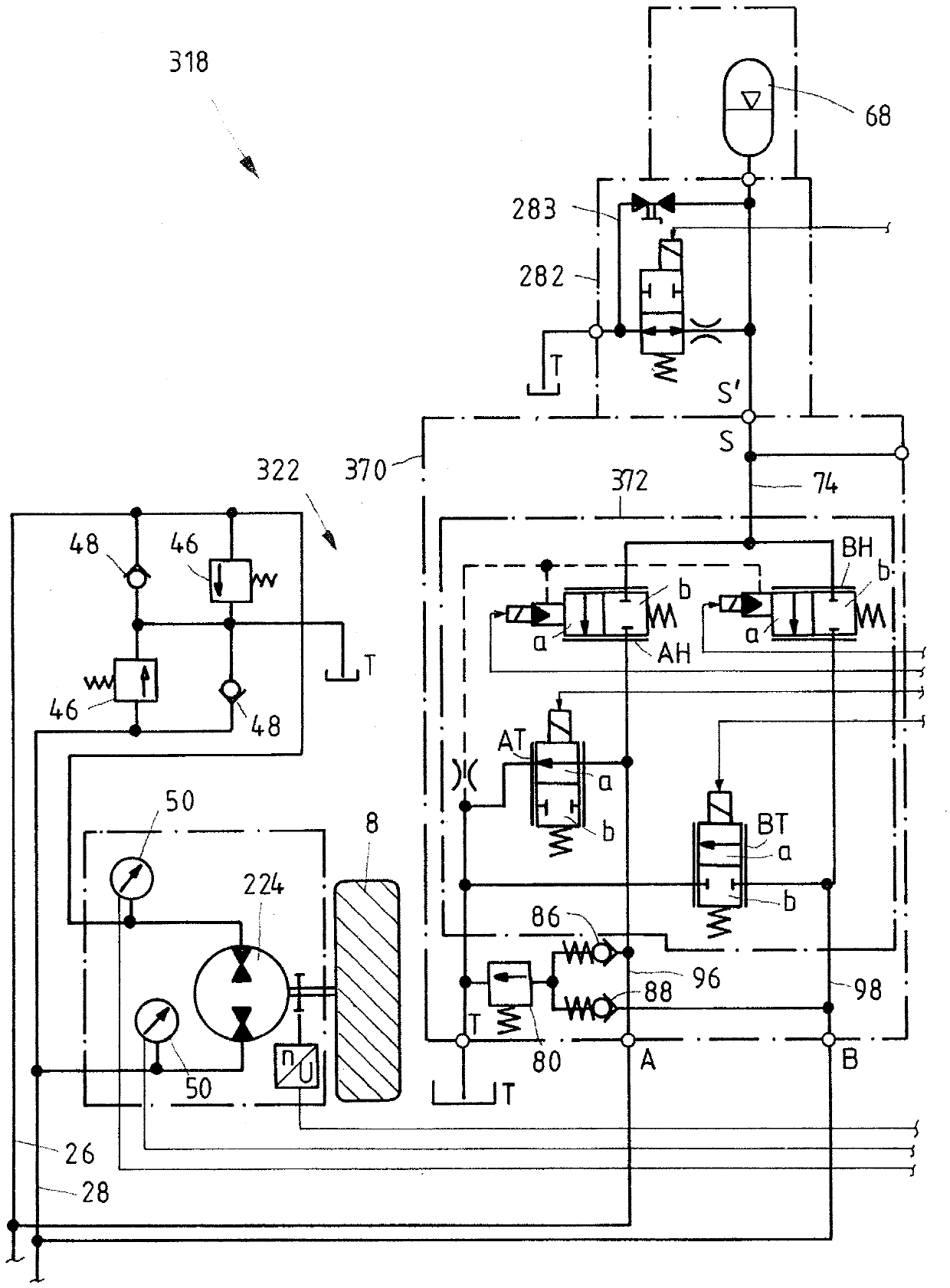

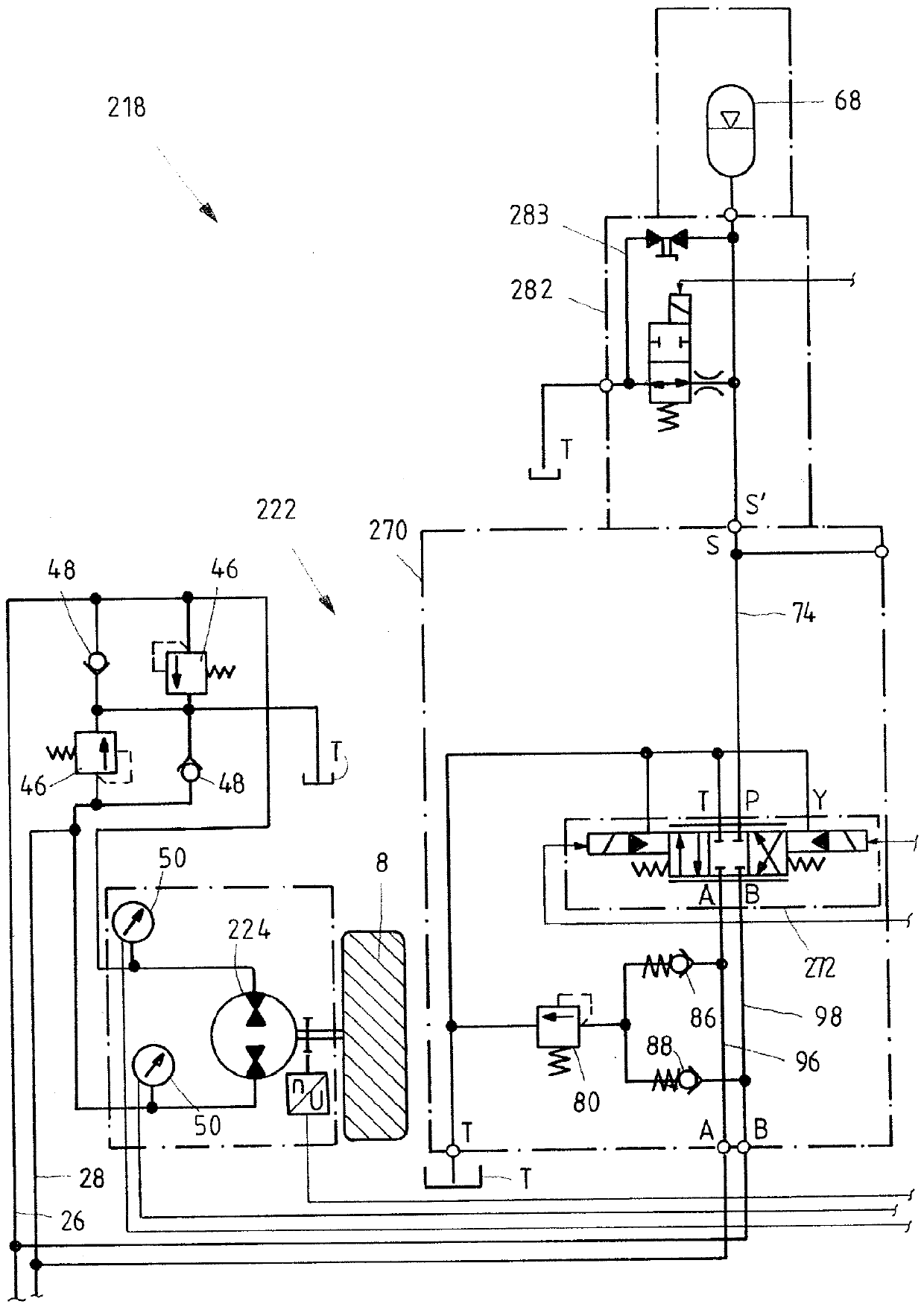

[0026] figure 1 A movable working machine 1 designed as an excavator is shown with a substructure 2 having crawler belts 4 of a traction drive of the excavator. An upper vehicle body 8 of the shovel 1 is rotatably connected to the bottom vehicle body 2 via a slewing mechanism 6 . A pivotable boom 10 , to which in turn a pivotable stick 12 is attached, is placed on the upper body 8 . A bucket 14 is pivotally fixed to the arm 12 . The upper body 8 is rotatable about the axis of rotation 16 relative to the lower body 2 via the swivel mechanism 6 .

[0027] The rotation of the upper vehicle body 8 relative to the bottom vehicle body 6 is realized by hydraulic drive. The upper body 8 must be braked at the end of the rotation. In this case braking energy must be applied. In order to be able to store this braking energy for later use, solutions are known in which a hydraulic machine driven by the rotating upper body supplies pressure medium into the hydraulic accumulator. At a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com