All-plastic LED bulb lamp for enhancing convection heat radiation

A technology for LED bulbs and LED light sources, applied in lampshades, lighting and heating equipment, components of lighting devices, etc., can solve the problems affecting the service life of LED bulbs, hindering the popularization of LED lamps, and increasing the cost of LED lamps. problem, to achieve good heat dissipation effect and luminous effect, shorten the molding cycle, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

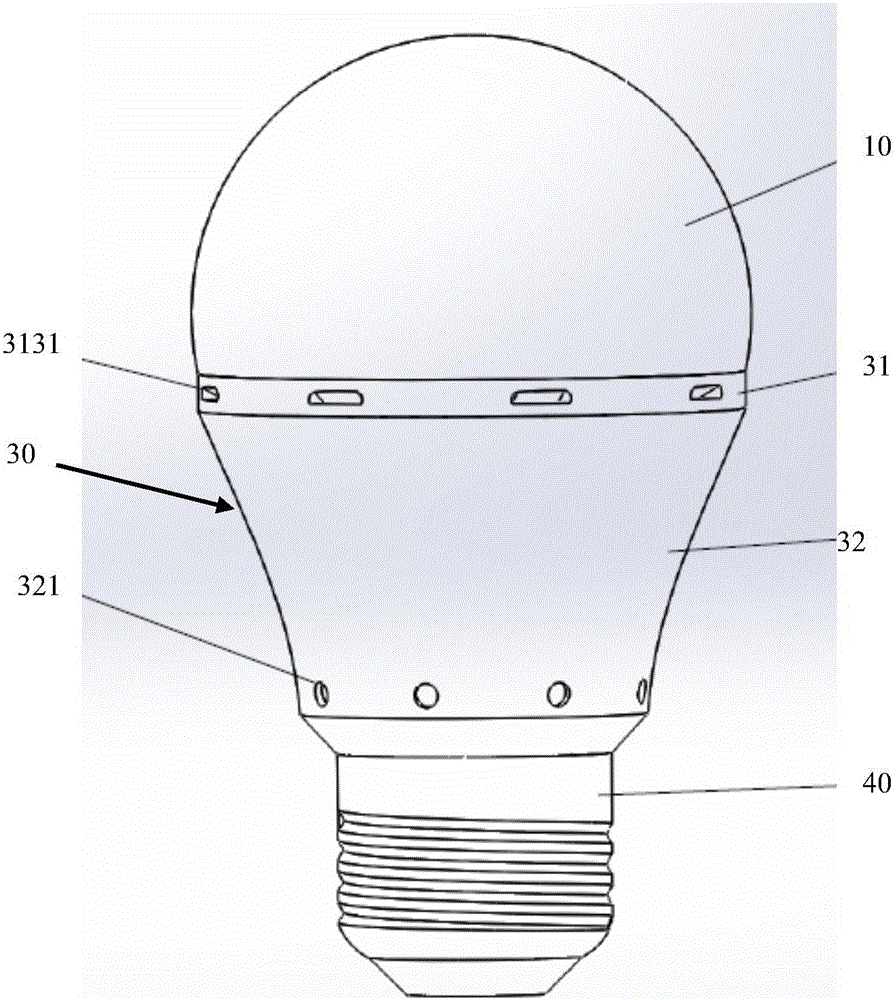

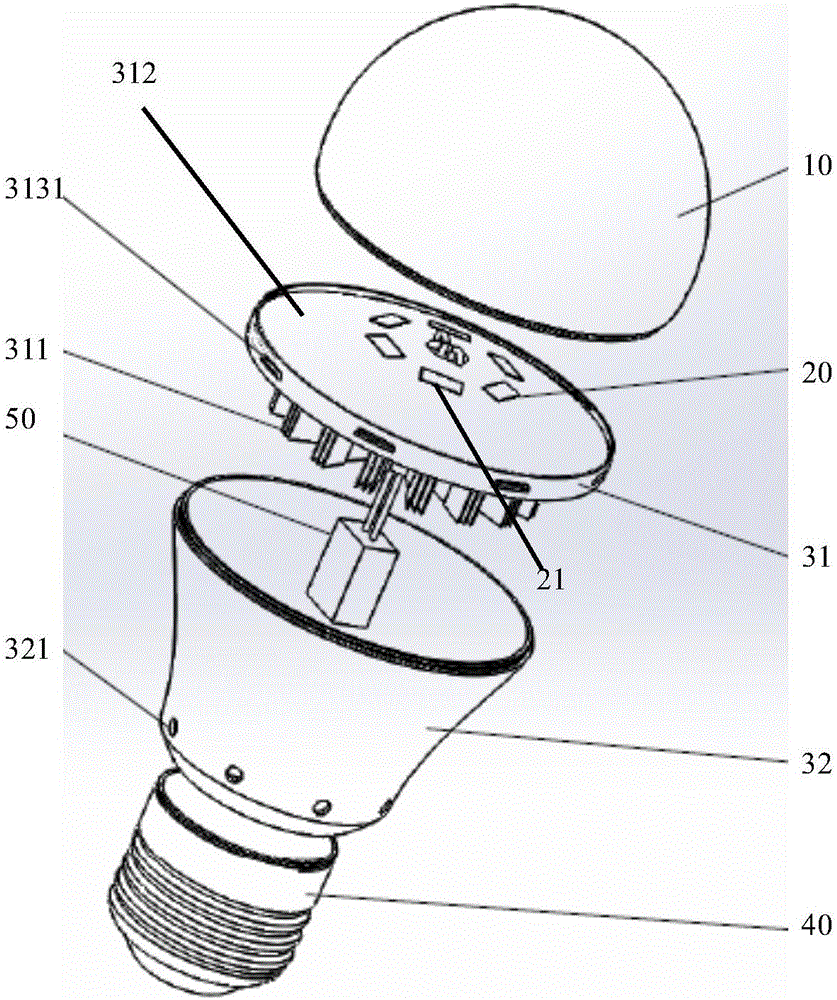

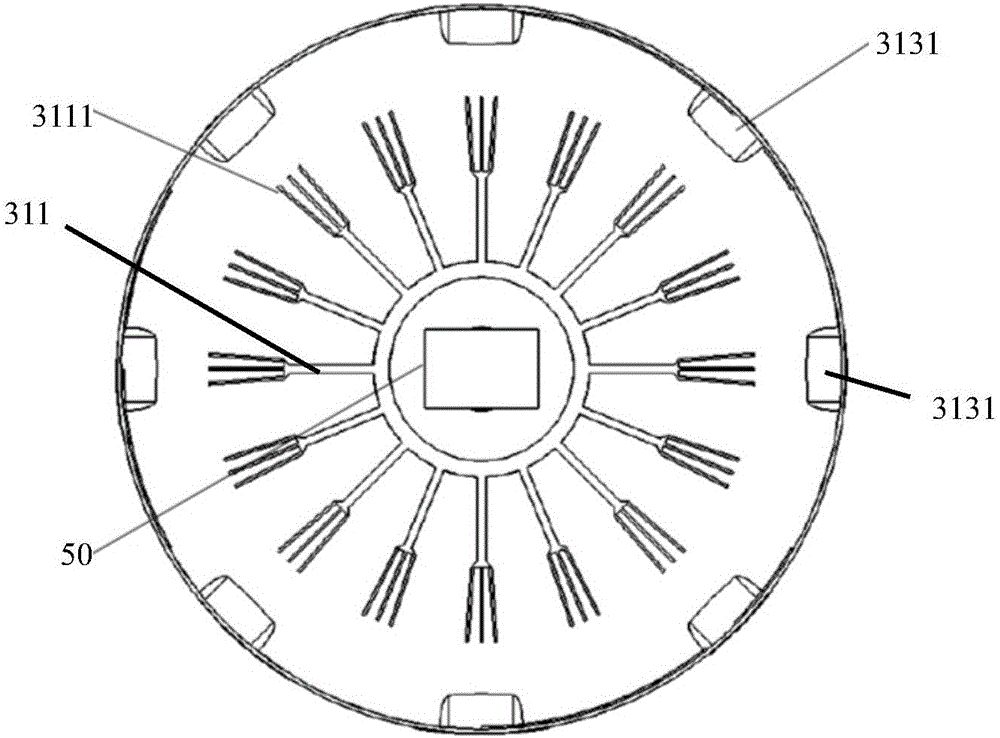

[0019] see Figure 1 to Figure 3 , the all-plastic LED bulb lamp with enhanced convection heat dissipation includes a bulb shell 10, an LED light source module 20, a radiator 30 and a lamp holder 40 from top to bottom, the LED light source module 20 is arranged on the top surface of the radiator 30, and the bulb The bulb 10 is threaded on the top of the heat sink 30 and covers the LED light source module 20. The heat sink 30 includes a heat dissipation plate 31 and a hollow heat conduction cylinder 32 screwed under the heat dissipation plate 31. The heat conduction cylinder 32 is set as an upper opening It is trumpet-shaped with a wide lower opening and a narrow lower opening. The lower opening of the heat conduction tube 32 is screwed to the lamp cap 40 . The inner cavity of the heat conduction tube 32 also accommodates a driving power supply 50 . Radial heat dissipation fins 311 are uniformly distributed along the circumferential direction on the bottom of the heat dissipati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com