Automobile headlamp assembly and automobile headlamp

A technology for automobile headlights and components, which is applied in the directions of headlights, vehicle parts, and components of lighting devices, etc., can solve the problems of vehicle visual interference, large beam divergence angle, and difficulty in cost and appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

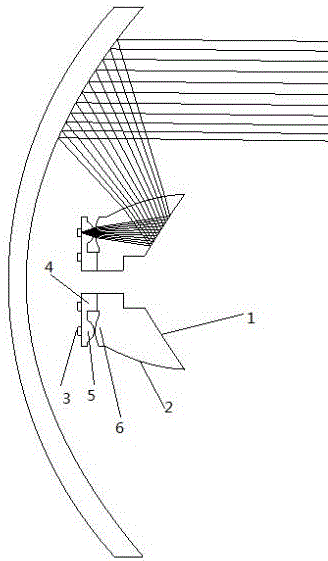

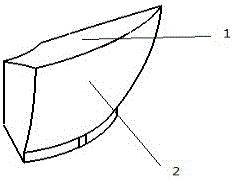

[0033] Such as Figures 1 to 6 As shown, the present invention discloses an automobile headlight assembly, which includes a light source, a condenser lens group and a light control lens mechanism, the condenser lens group is located between the light source and the light control lens mechanism; the light control lens The mechanism includes a reflection surface 1 that only reflects the light beam, and an exit surface 2 that refracts the light beam reflected by the reflection surface 1; the reflection surface 1 cooperates with the exit surface 2, so that the light beam generated by each light source is reflected The virtual image points formed behind the surface 1 and the exit surface 2 are all at the same position on the geometric central axis of the light control lens mechanism.

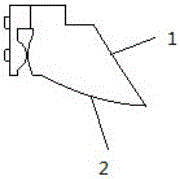

[0034] The condensing lens group includes a first condensing lens group and a second condensing lens group juxtaposed to each other; the first condensing lens group is arranged on the lens seat 4, an...

Embodiment 2

[0045] This embodiment is substantially the same as Embodiment 1, the difference is that: the condensing lens group includes a first condensing lens group and a second condensing lens group juxtaposed to each other; the first condensing lens group and the second condensing lens group The two light-condensing lens groups are all arranged on the lens seat 4 .

[0046] The first condensing lens group includes several first curved lenses 5 that are evenly arranged in a circular array on the lens holder 4, and the second condensing lens group includes a number of second curved lenses 6 that are evenly arranged in a circular array on the lens holder 4. Above, the first curved lens 5 and the second curved lens 6 are matched with each other and located on the same axis.

[0047] The light control lens mechanism includes a concave reflective surface 1 located in the middle, an outgoing surface 2 located on the side, and a bottom surface. The outgoing surface 2 is connected to the refle...

Embodiment 3

[0049] Such as Figure 5 As shown, this embodiment is substantially the same as Embodiments 1 and 2, except that the reflective surface 1 is spliced by several fan-shaped / fan-shaped reflective units 7; wherein the reflective unit 7 is the same as the LED light source 3, the second A curved lens 5 and a second curved lens 6 are matched.

[0050] Since the reflective surface is spliced by several fan-shaped / fan-shaped reflective units, the reflection is no longer continuous. Each fan-shaped / fan-shaped reflective unit reflects the beam to a designated area, which can facilitate the adjustment of the beam. Concentrating the light beam is convenient for adjusting the uniformity of brightness; each fan-shaped / fan-shaped reflective unit corresponds to each LED light source, and each fan-shaped / fan-shaped reflective unit reflects the light beam emitted by the corresponding LED light source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com