Method for effectively preventing inner leakage of liquid ammonia water cooler

A liquid ammonia water and cooler technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as heat exchange tube corrosion, internal leakage of circulating water cooler, heat exchange tube breakage, etc., to reduce replacement costs, Avoid contamination and increase the effect of life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

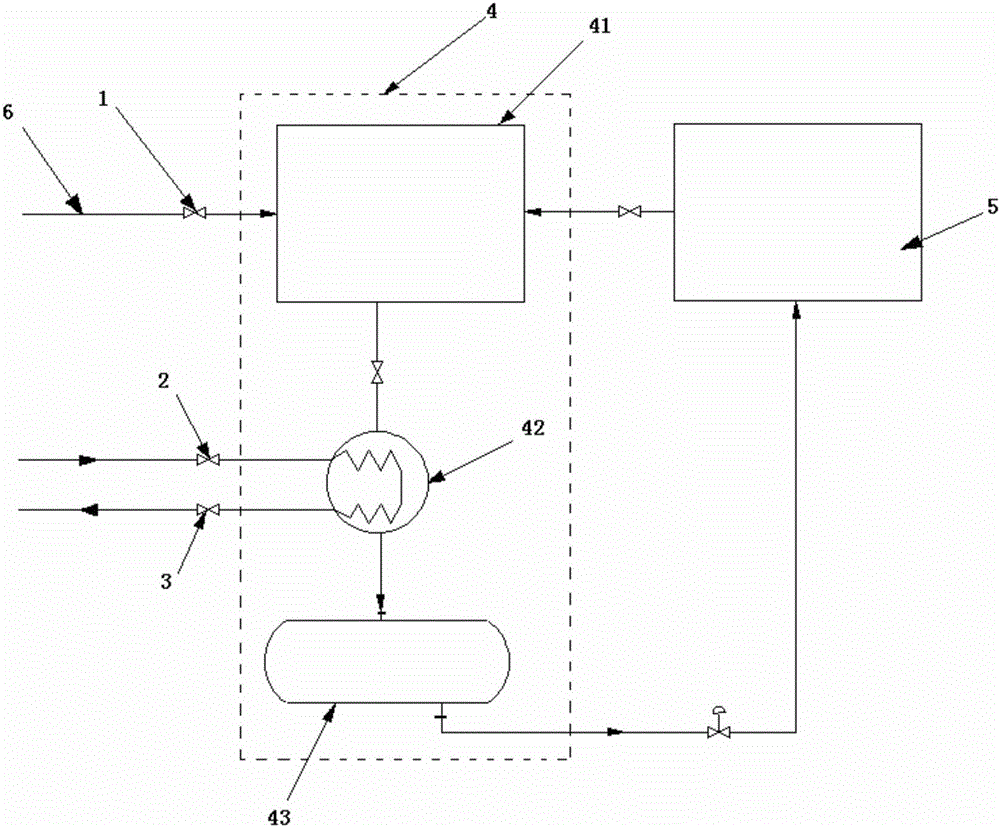

[0016] A method for effectively preventing internal leakage of the liquid ammonia water cooler of the present invention comprises the following steps: figure 1 As shown, the ammonia compression device 41, the circulating water cooler 42, and the liquid ammonia tank 43 are sequentially connected in series through pipelines to form the ammonia refrigeration system 4, wherein the ammonia compression device 41 and the liquid ammonia tank 43 are all connected with the low-temperature methanol washing system 5 , the ammonia compression device 41 is now connected to the nitrogen input pipeline 6 provided with the side hand valve 1. After the ammonia refrigeration system 4 is stopped, the water inlet valve 2 and the water outlet valve 3 of the circulating water cooler 42 are opened to avoid completely closing and maintain a constant The circulating water flow rate ensures that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com