Glass fiber drying treatment device

A technology of drying treatment and glass fiber, which is applied in the drying of solid materials, local stirring dryers, dryers for static materials, etc. It can solve the problems of affecting processing, pollution and damage, and poor effect, saving energy costs and being easy to operate. , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

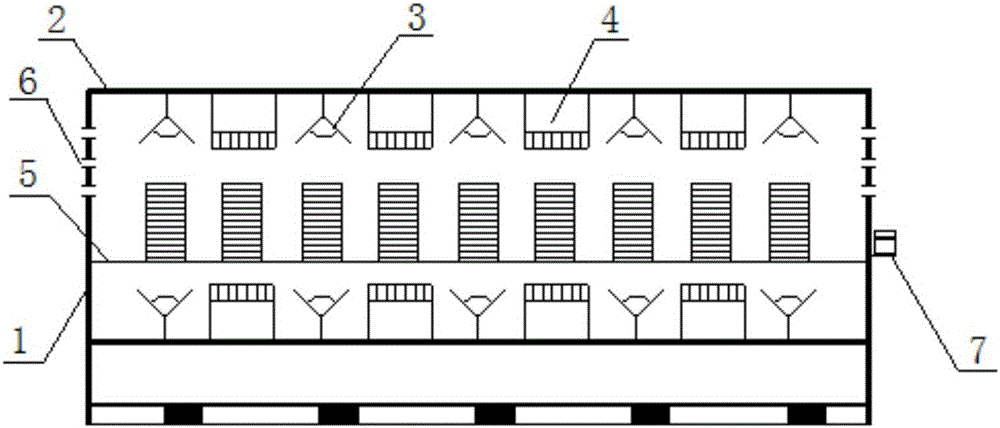

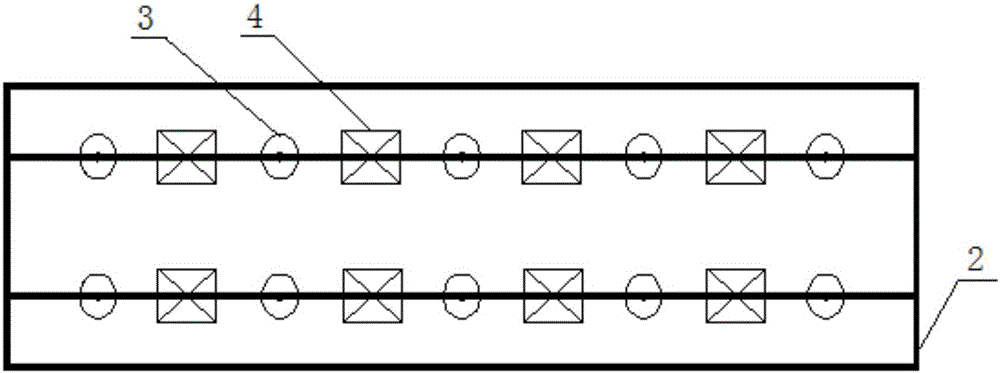

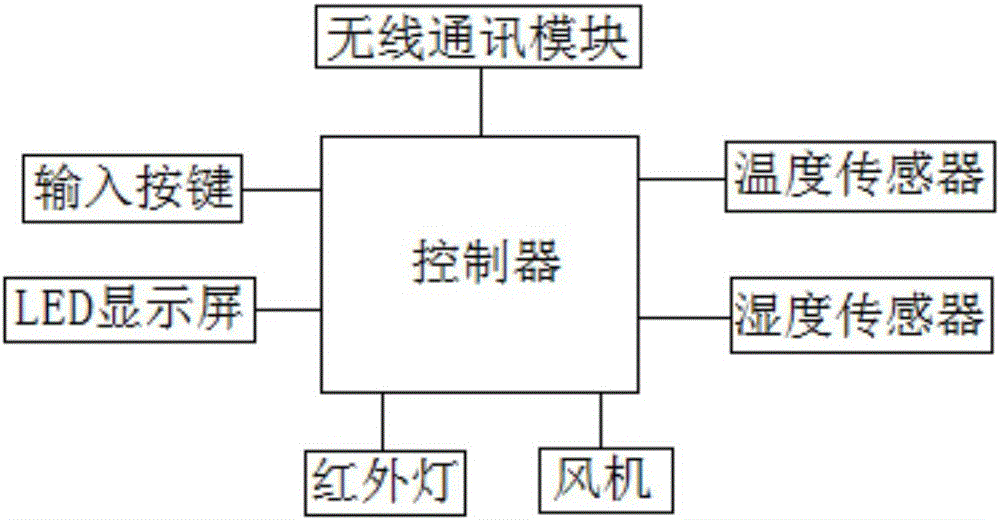

[0013] Such as Figure 1 to Figure 3 As shown, a glass fiber drying treatment device includes a storage box 1, the top and bottom of the storage box 1 are respectively provided with a stainless steel frame 2, and the stainless steel frame 2 is provided with an infrared lamp 3 and a fan 4, and the infrared lamp 3 and Fans 4 are connected in parallel with each other, relatively evenly staggered and installed on the stainless steel frame 2, and connected to the control device 7 installed on the outer wall of the storage box 1; the middle layer of the storage box 1 is provided with a placement net 5, and multiple A glass fiber hole 6, a temperature sensor and a humidity sensor are provided inside the storage box 1, and the temperature sensor and the humidity sensor are respectively connected to the control device 7.

[0014] Preferably, the control device 7 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com