Device and method for in-situ destruction of unexploded bombs

A technology for destroying devices and unexploded bombs, which is applied in the direction of blasting and explosives, which can solve the problems of low safety factor and high cost of destroying devices, and achieve the effects of long heating time, convenient large-scale equipment, and efficient destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

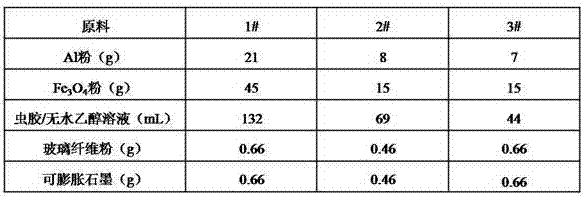

[0039] Embodiment 1: Preparation of combustible glue.

[0040] Weigh Al powder, Fe 3 o 4 powder, mix the two evenly to get Al / Fe 3 o 4 Mix the powder; weigh shellac, add it to absolute ethanol, and prepare a shellac absolute ethanol solution with a mass concentration of 5%; weigh Al / Fe 3 o 4 Mix the powder, add it to the above-mentioned shellac absolute ethanol solution, and stir until it is uniform to obtain a mixed solution; add glass fiber powder to the above-mentioned mixed solution, after stirring evenly, then add expandable graphite, and stir until it is uniform to obtain a combustible glue.

[0041] The dosage of each raw material is shown in the table below, wherein, the shellac / dehydrated ethanol solution in the 1# formula is prepared by adding 6.5g shellac to 156mL absolute ethanol; the shellac / dehydrated alcohol solution in the 2# formula The ethanol solution is prepared by adding 5g shellac to 100mL absolute ethanol; the shellac / absolute ethanol solution in t...

Embodiment 2

[0043] Embodiment 2: Device for destroying unexploded bombs on the spot.

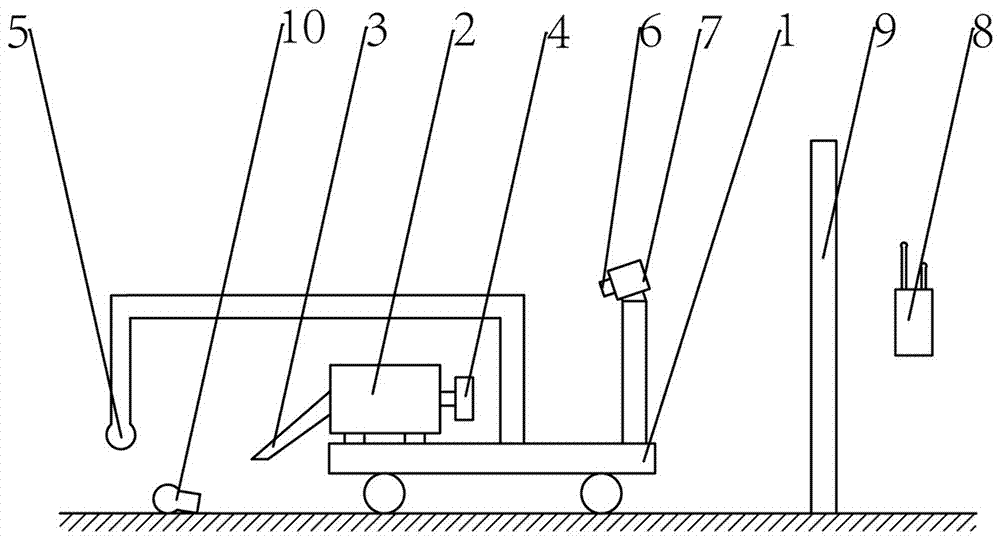

[0044] Such as figure 1As shown, the device of the present invention is mainly composed of a movable base 1, a combustible rubber extruding mechanism, an ignition mechanism, a video monitoring system, a display platform (not shown) and a remote control 8 and other parts.

[0045] The movable base 1 is used as a carrier for carrying other parts and can move together with other parts. The base 1 can be a wheeled trolley or a crawler trolley.

[0046] The combustible rubber extruding mechanism includes a rubber storage tank 2 , an extruding pipe 3 and an extruding mechanism 4 . The glue storage tank 2 is arranged on the front end of the base 1, and is used for storing combustible glue, and the combustible glue is made by Example 1. The extruding tube 3 is arranged at the front end of the tank body of the rubber storage tank 2, and serves as an extruding channel for the combustible rubber. The tube body...

Embodiment 3

[0050] Embodiment 3: method for destroying unexploded bombs on the spot.

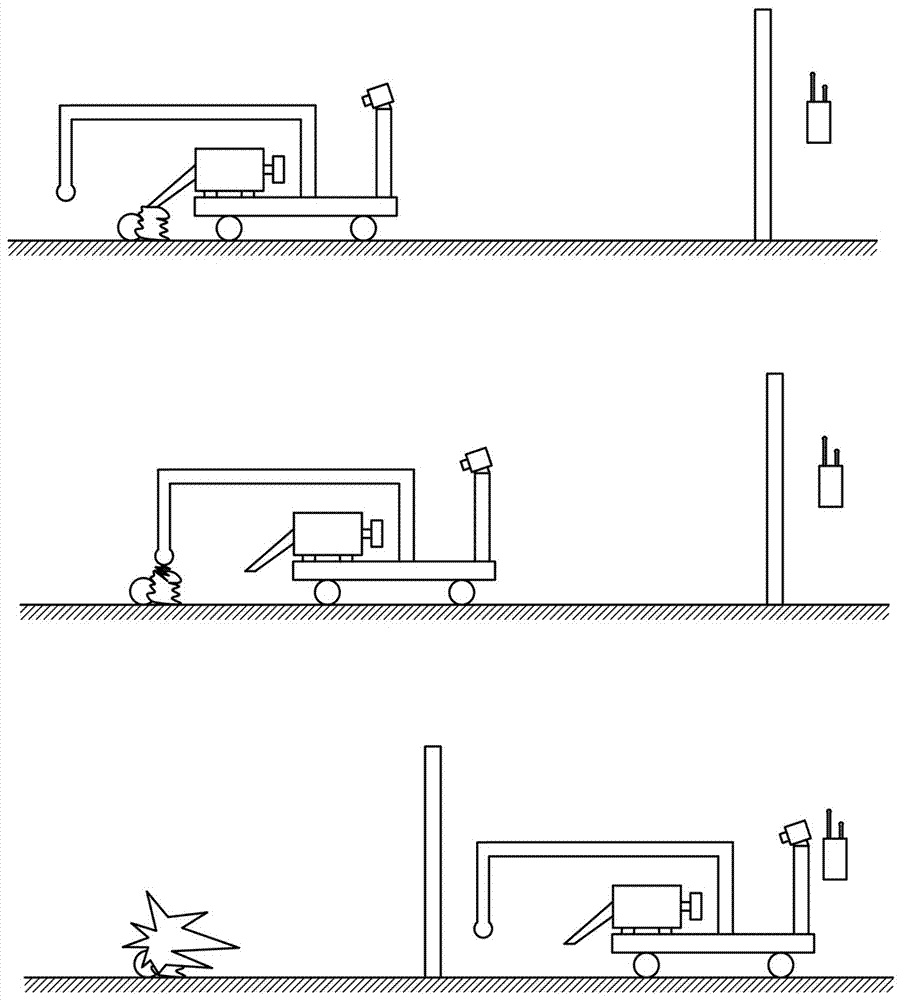

[0051] The inventive method comprises the following steps:

[0052] A, the said unexploded ordnance destruction device on the spot of embodiment 2 is set;

[0053] b. Use the remote control to control the base to move towards the position of the unexploded bomb. At the same time, through the video display on the display platform, when the lower port of the extrusion tube of the combustible rubber extrusion mechanism is located directly above the fuze body of the unexploded bomb, the control The base stops running;

[0054] c. Control the extruding mechanism of the combustible rubber extruding mechanism to extrude the combustible rubber in the rubber storage tank. Observe through the video screen on the display platform. When the extruded combustible rubber completely covers the fuze body of the unexploded bomb, control The extrusion mechanism stops extrusion;

[0055] d. Control the base to move away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com