Method for determining nickel-based single crystal high-temperature alloy residual segregation

A nickel-based single crystal, superalloy technology, applied in the analysis of materials, material analysis by optical means, material analysis by measuring secondary emission, etc., can solve the large difference in segregation, does not explain the residual segregation determination method, does not describe Residual segregation determination method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

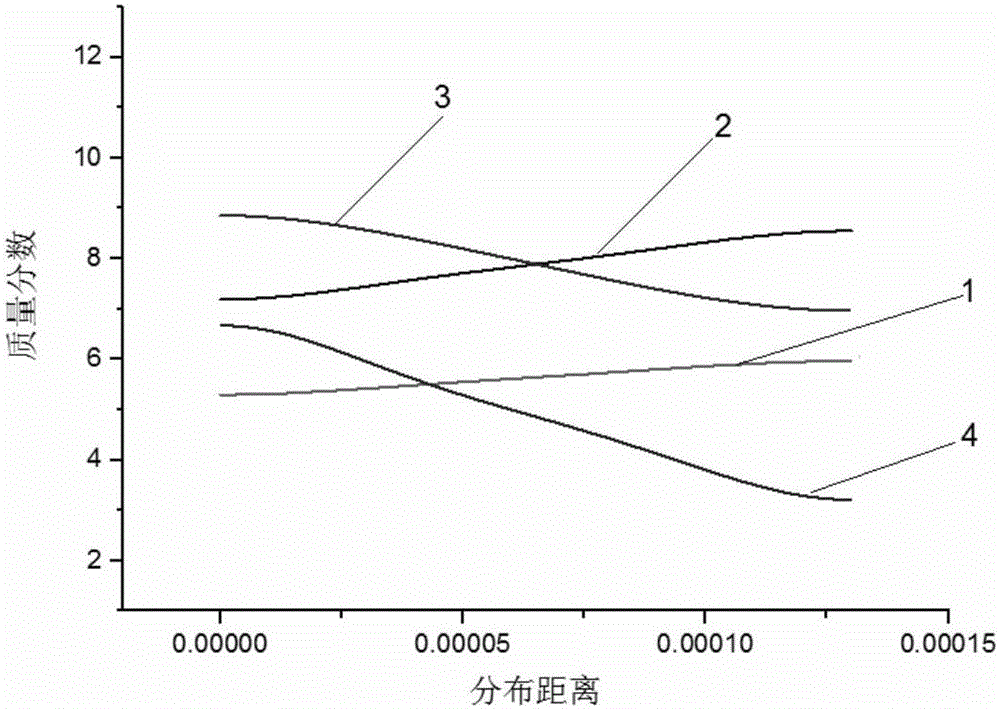

Embodiment 1

[0044] This embodiment is a method for determining the residual segregation of nickel-based single crystal superalloy elements. The determination of residual segregation of nickel-based single crystal superalloy elements refers to the four most important segregation elements Al, Ta, W and Re in nickel-based single crystal superalloy.

[0045] In this embodiment, the residual segregation ratios of Al, Ta, W and Re are calculated.

[0046] The nickel-based single crystal superalloy is in cast state, composed of Cr, Mo, Al, Co, W, Re, Ta, Hf, C, B and Ni, and its nominal composition is: the content of Cr is 3.6%, the content of Mo The content of Al is 1.8%, the content of Al is 5.7%, the content of Co is 9%, the content of W is 6%, the content of Re is 4%, the content of Ta is 8%, and the balance is Ni. The stated percentages are all mass percentages.

[0047] The specific implementation steps of this embodiment are:

[0048] Step 1, preparing a metallographic sample: sampling...

Embodiment 2

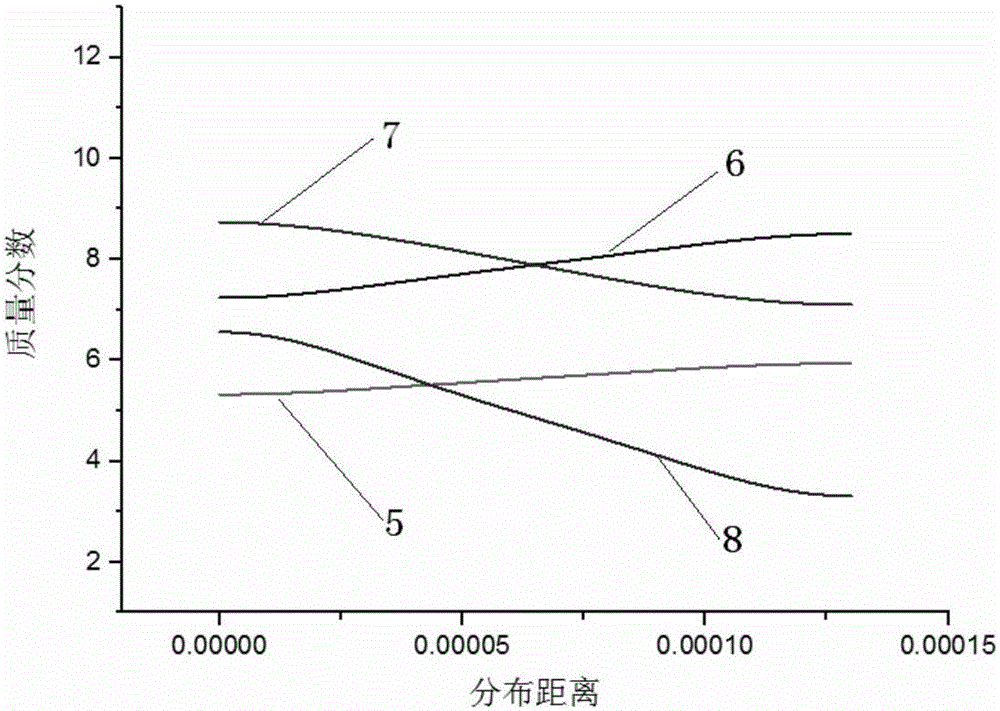

[0075] This embodiment is a method for determining the residual segregation of nickel-based single crystal superalloy elements. The determination of residual segregation of nickel-based single crystal superalloy elements refers to the four most important segregation elements Al, Ta, W and Re in nickel-based single crystal superalloy.

[0076] In this embodiment, the residual segregation ratios of Al, Ta, W and Re are calculated.

[0077] The nickel-based single crystal superalloy is in cast state, composed of Cr, Mo, Al, Co, W, Re, Ta, Hf, C, B and Ni, and its nominal composition is: the content of Cr is 3.5%, the content of Mo The content of Al is 1.7%, the content of Al is 5.75%, the content of Co is 9.1%, the content of W is 6%, the content of Re is 4%, the content of Ta is 8%, and the balance is Ni. The stated percentages are all mass percentages.

[0078] The specific implementation steps of this embodiment are:

[0079] Step 1, preparing a metallographic sample: sampl...

Embodiment 3

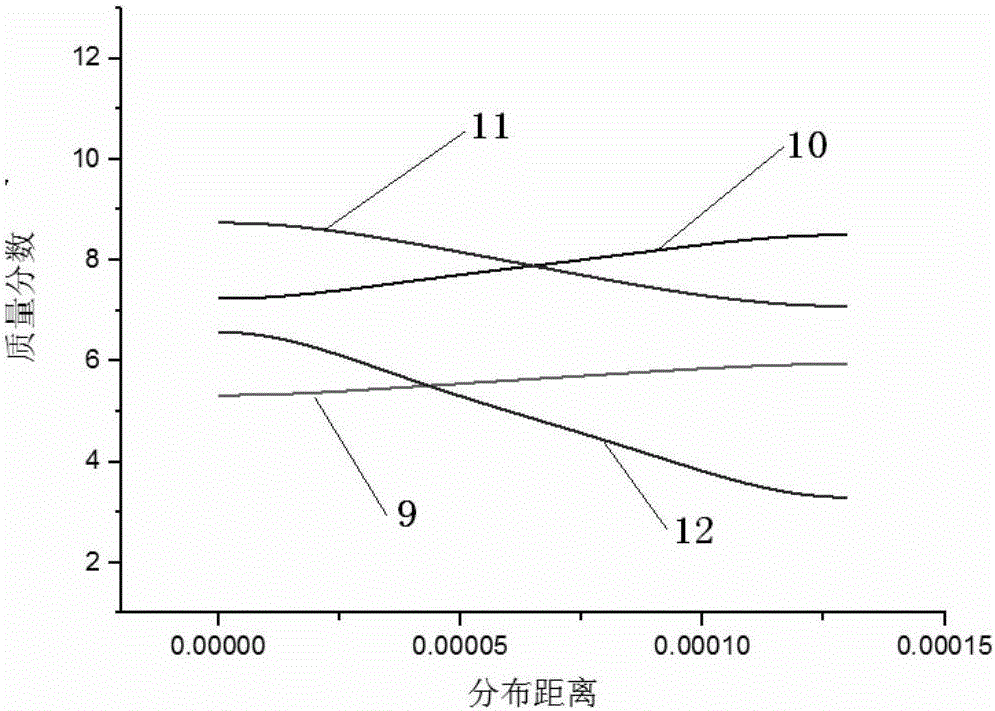

[0106] This embodiment is a method for determining the residual segregation of nickel-based single crystal superalloy elements. The determination of residual segregation of nickel-based single crystal superalloy elements refers to the four most important segregation elements Al, Ta, W and Re in nickel-based single crystal superalloy.

[0107] In this embodiment, the residual segregation ratios of Al, Ta, W and Re are calculated.

[0108] The nickel-based single crystal superalloy is in cast state, composed of Cr, Mo, Al, Co, W, Re, Ta, Hf, C, B and Ni, and its nominal composition is: the content of Cr is 3.62%, the content of Mo The content of Al is 1.83%, the content of Al is 5.7%, the content of Co is 9%, the content of W is 6%, the content of Re is 4.1%, the content of Ta is 8%, and the balance is Ni. The stated percentages are all mass percentages.

[0109] The specific implementation steps of this embodiment are:

[0110] Step 1, preparing a metallographic sample: samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com