Basin-type insulator crack detector based on fiber gratings

A basin-type insulator, fiber grating technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of difficult long-term fixed monitoring, ground discharge of circuit breakers, difficulty in capturing partial discharge signals, etc., and achieves simple and reliable detection methods and simple structures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

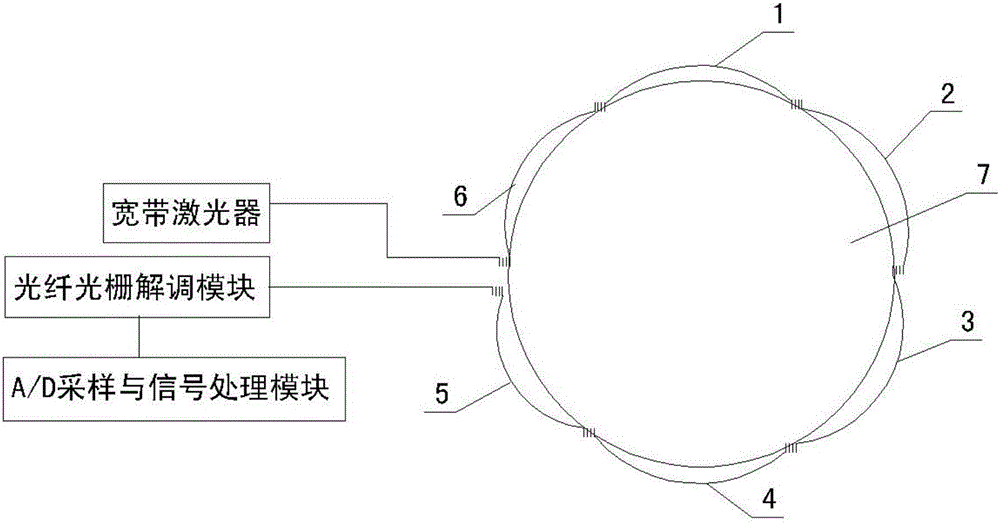

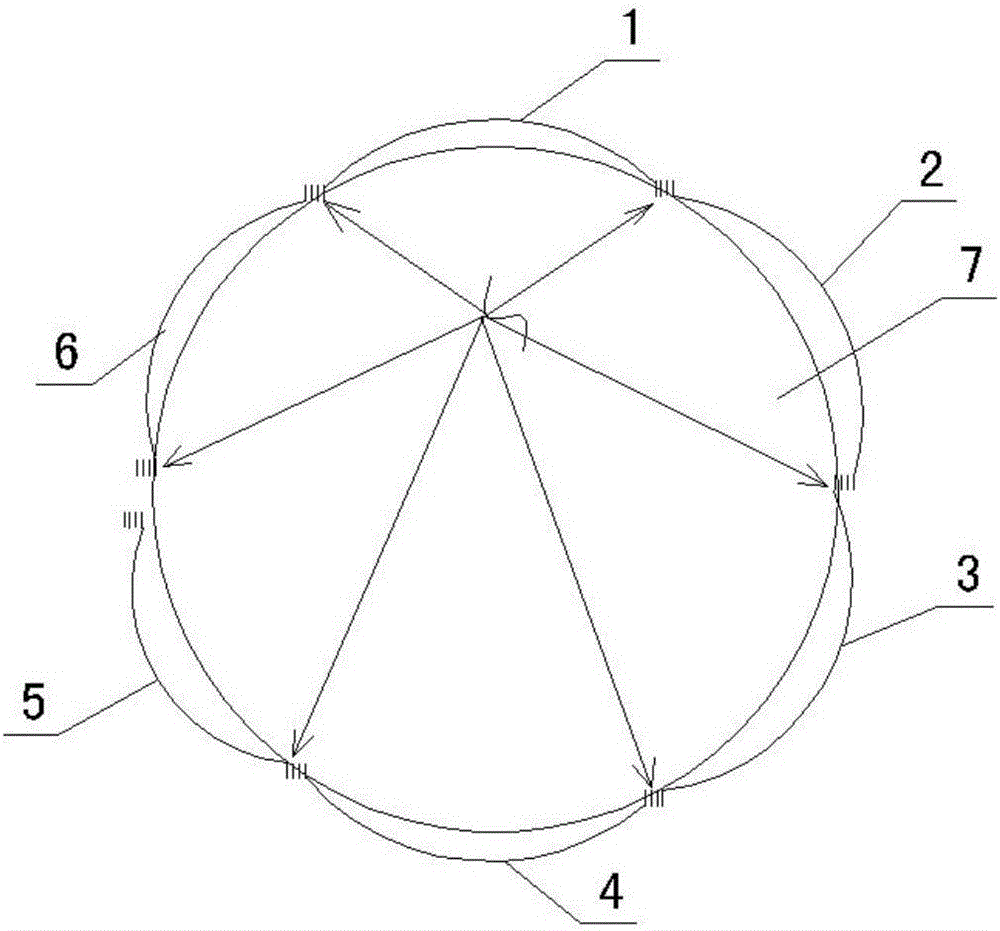

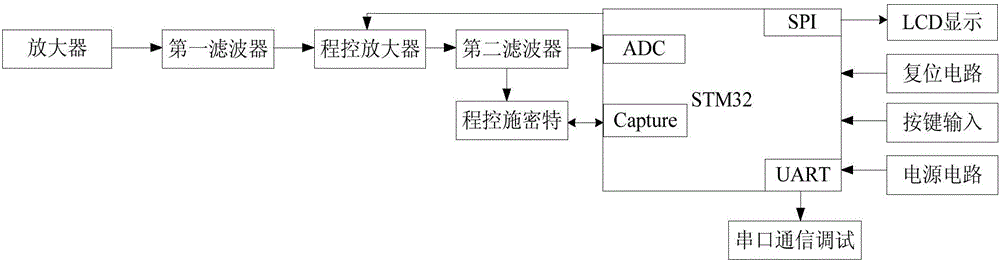

[0018] see figure 1 with figure 2 In this embodiment, the basin-type insulator crack detector based on fiber gratings includes a broadband laser, six fiber gratings connected in series on an optical fiber, a fiber grating demodulation module, an A / D sampling and processor module; The six fiber gratings are pasted around the outer circumference of the pot insulator. One end of the fiber is connected to the broadband laser, and the other end is connected to the fiber grating demodulation module. The output signal of the fiber grating demodulation module is connected to the A / D sampling and processor module. , the A / D sampling and processor module uses the A / D sampler to obtain the sampled data after data conversion, and uses the processor to perform signal judgment on the sampled data;

[0019] When the pot insulator cracks due to process, pressure, partial discharge, etc., the stress wave generated at the moment of cracking propagates to the outer diameter surface of the pot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com