Fiber bragg grating tuning method and device thereof

A fiber grating, organic technology, applied in cladding fiber, optical waveguide light guide, optics, etc., can solve the problem of slow tuning speed of fiber grating, and achieve the effect of large wavelength change range, efficient tuning and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

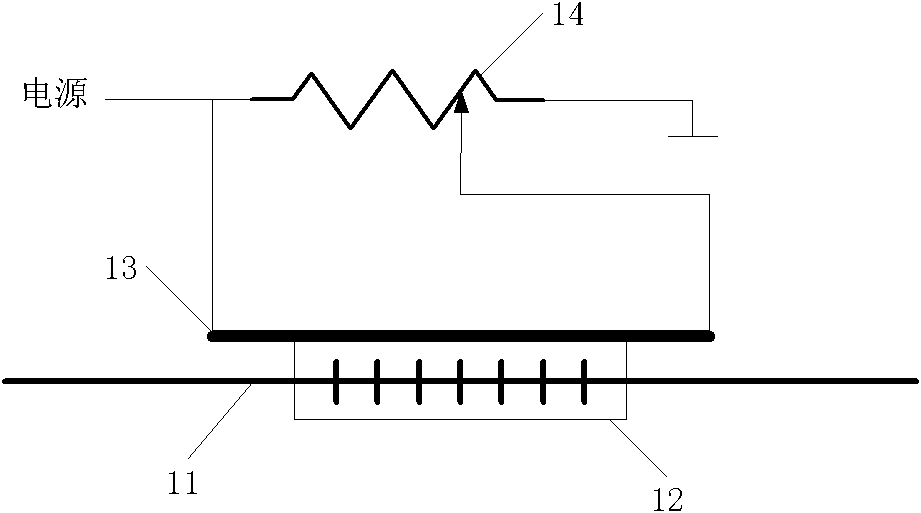

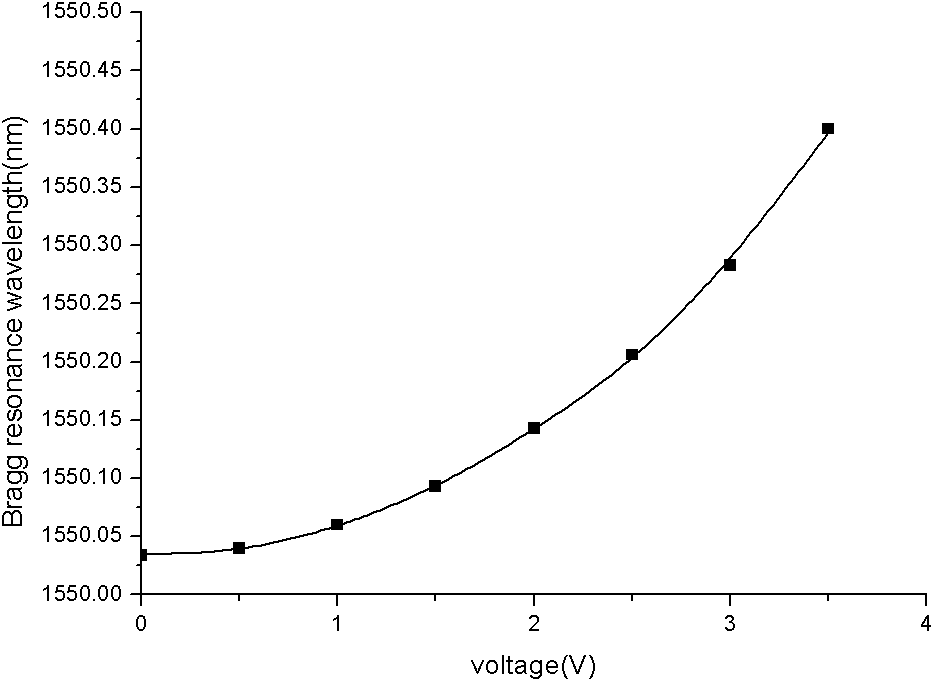

[0015] Example 1 as figure 1 As shown, the device includes a fiber Bragg grating 11, an organic polymer polyimide 12 coated on the surface of the fiber grating, a tungsten wire 13, a variable resistor 14 and a circuit board (not shown in the figure). In this embodiment, the tungsten wire and the variable resistor are temperature control modules. The length of the fiber Bragg grating is 20mm, the fiber Bragg grating wavelength is 1550.03nm; the length of the polyimide coating is 20mm; the length of the tungsten wire is 30mm, the fiber Bragg grating and the tungsten wire are close together, and the two ends of the tungsten wire are welded On the board, in parallel with the variable resistor. The voltage across the tungsten wire is controlled by changing the resistance of the variable resistor, that is, the surface temperature of the tungsten wire is controlled, thereby controlling the stretching degree of the polyimide coating layer, so that the central wavelength of the fiber ...

Embodiment 2

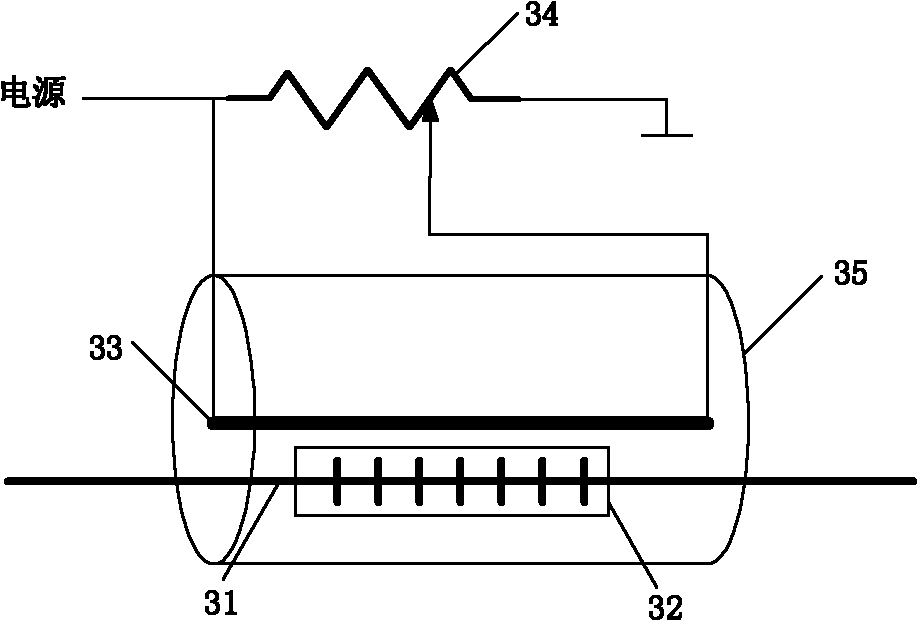

[0016] Example 2 as image 3 As shown, the device includes a fiber grating 31 , an organic polymer acrylate 32 coated on the surface of the fiber grating, a tungsten wire 33 , a variable resistor 34 and a vacuum sleeve 35 . In this embodiment, the tungsten wire, the variable resistor and the vacuum sleeve are temperature control modules. The length of the fiber grating is 20mm, the coating length of the organic polymer is 20mm; the length of the tungsten wire is 30mm; the length of the vacuum sleeve is 20mm, and the diameter is 15mm. The end is inserted and soldered on the circuit board, connected in parallel with the variable resistor, and the fiber grating is placed near the central axis of the vacuum sleeve parallel to the tungsten wire. The voltage at both ends of the tungsten wire is controlled by changing the resistance of the variable resistor, that is, the temperature distribution in the vacuum sleeve is controlled, thereby controlling the stretching degree of the org...

Embodiment 3

[0017] Example 3 as Figure 4 As shown, the device includes a fiber grating 41 , an organic polymer polyetherimide 42 coated on the surface of the fiber grating, and a thermostat 43 . In this embodiment, the thermostat is a temperature control module. The length of the fiber grating is 20 mm, and the coating length of the organic polymer is 20 mm. The fiber grating coated with organic polymer is placed in a constant temperature box. The stretching degree of the organic polymer coating layer is controlled by changing the constant temperature value of the thermostat, so that the central wavelength of the fiber grating changes with the change of temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com