A test method for the dispersion performance of engine oil soot

A technology of dispersion performance and test method, applied in the direction of material inspection products, etc., can solve the problems of simulating the dispersion performance of oil products, affecting the bench correlation of dispersion, saving money and manpower, short test period and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for testing engine oil soot dispersion performance, comprising the following steps:

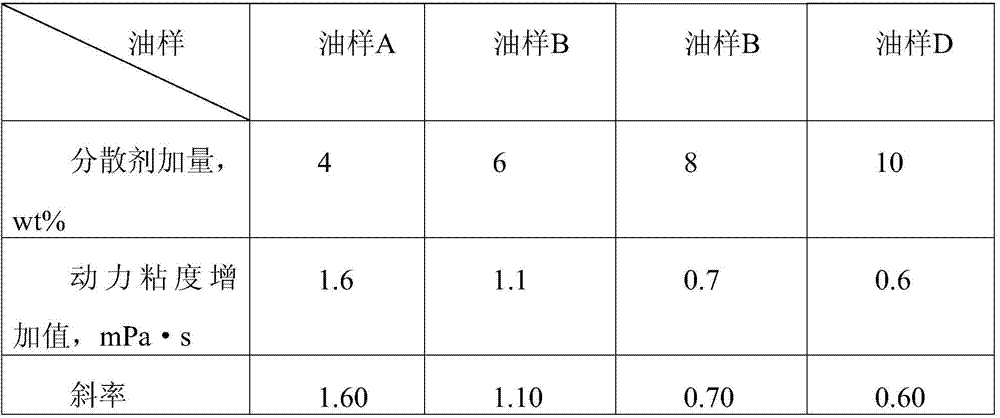

[0026] A. Separation of the oil product tested by Cummins ISM bench test in an ultracentrifuge, the centrifuge speed is 10000-150000rpm, the separation time is 5h, remove the upper liquid, take out the bottom soot particles and stir them evenly, add them to the engine oil, and Stir and mix evenly to form the oil sample to be tested. The oil sample to be tested is stirred at a speed of 2000-20000rpm, and the stirring time is 1-60min, but not limited to this; the oil is separated in the ultracentrifuge. The added amount of the dispersant is (mass percentage content) 4%, but not limited thereto.

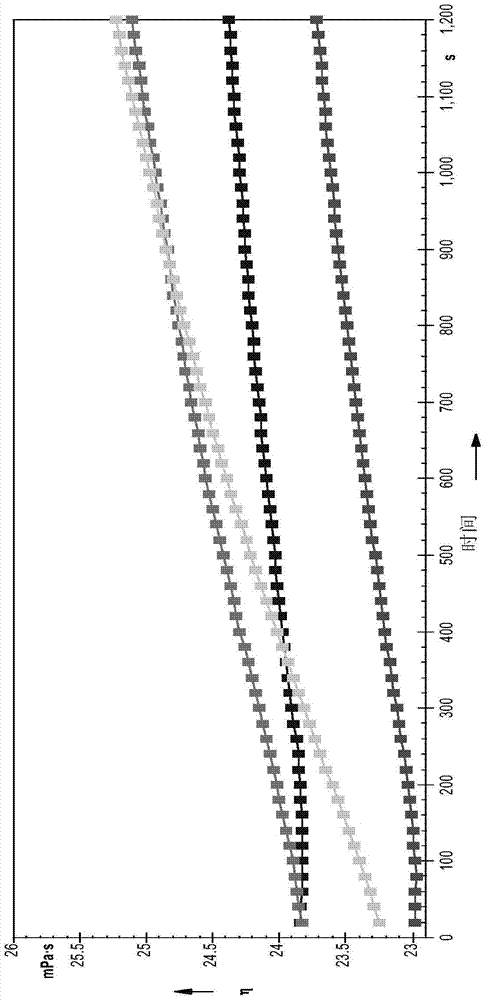

[0027] B. The oil sample to be tested is placed in a rotational rheometer, and the viscosity of the oil sample is measured over time under a fixed shear rate and a fixed temperature. figure 1 As shown, the shear rate of the rotational rheometer is 10-300s -1 within, preferably 50s -1...

Embodiment 2

[0035] Separation of the oil product in the DV4 bench test in the ultracentrifuge, the centrifuge speed is 10000rpm, the separation time is 10 hours, the upper liquid is removed, the bottom soot particles are taken out and stirred evenly, then added to the engine oil, the soot particles and the engine The ratio of the oil is 10:90, and then stirred at a speed of 10000 rpm for 20 minutes under a high-speed mixer, and the two are mixed evenly to form the oil sample E to be tested. The oil sample E in this example is a commercial fully formulated engine oil with a quality grade of CF-4.

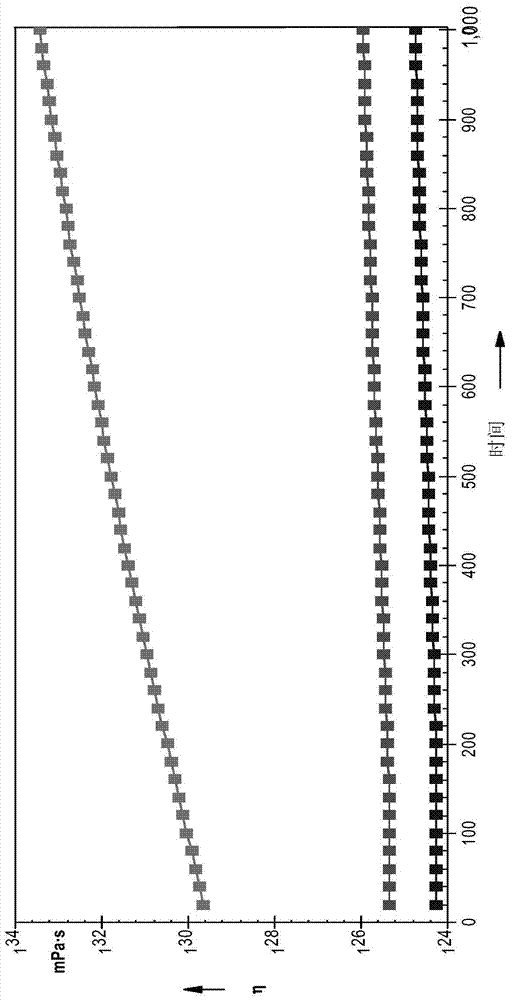

[0036] Put the oil sample E in the rotational rheometer, set the shear rate of the rotational rheometer to 100s-1, and the temperature to 40°C. Under these conditions, test for 1000 seconds, and measure the power of the oil from time t0 to time t1200 Viscosity increase value, and calculate its slope size, see figure 2 .

[0037] Then take oil sample F and oil sample G. The difference from oil...

Embodiment 3

[0043] Separation of the oil product in the MackT-8E bench test in an ultracentrifuge, the centrifuge speed is 80000rpm, the separation time is 16h, the upper liquid is removed, the bottom soot particles are taken out and stirred evenly, then added to the engine oil, the soot particles The ratio of the engine oil was 30:70, and then stirred at a speed of 5000 rpm for 40 minutes under a high-speed mixer, and the two were mixed evenly to form the oil sample H to be tested. The oil sample H in this example is a commercial fully formulated engine oil with a quality grade of CJ-4.

[0044] Put the oil sample H in the rotational rheometer, set the shear rate of the rotational rheometer to 200s-1, and the temperature to 120°C. Under these conditions, test for 800 seconds, and measure the power of the oil from time t100 to time t700 Viscosity increase value, and calculate its slope size.

[0045] Take oil sample I again, the difference from oil sample H is that this oil sample is a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com