White tea processing method

A processing method and technology of white tea, which is applied in the field of tea processing, can solve the problems of low yield of white tea and the inability to effectively improve the active ingredients of finished white tea, and achieve the effects of rich taste, clear sweetness, increased content, and increased leaching rate of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

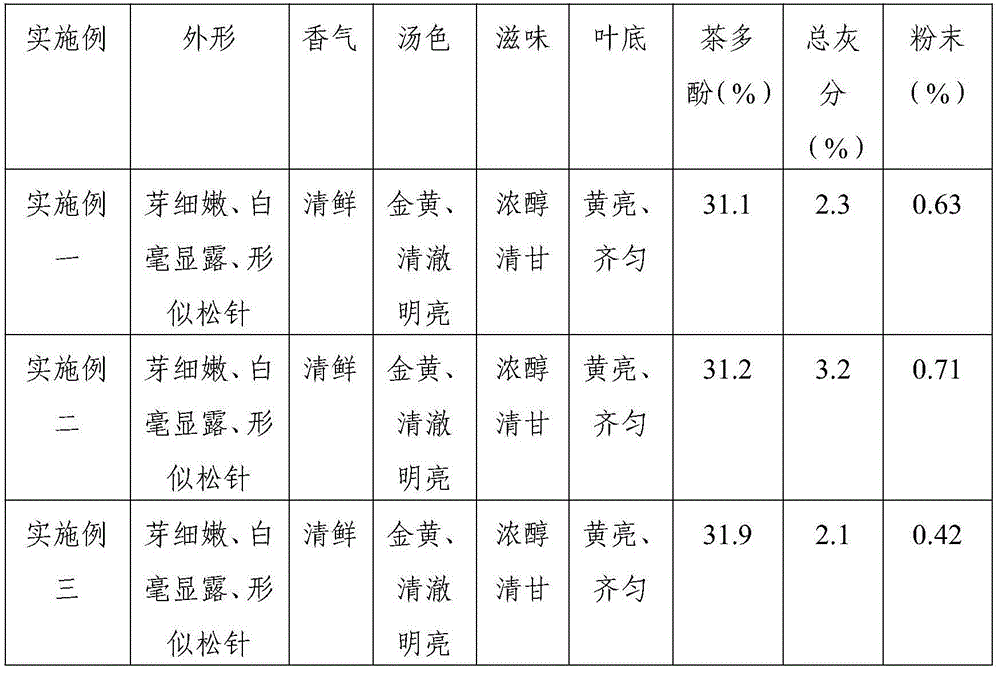

Examples

Embodiment 1

[0021] A processing method for white tea, comprising the following steps:

[0022] (1) Picking: Pick the fresh leaves of one bud and one leaf from the tea tree of large-leaf species clone;

[0023] (2) Withering: the fresh leaves of the tea tree are evenly spread on the withering tank with a thickness of 2cm, placed at room temperature for 10h, and the withered leaves with a moisture content of 64% are obtained;

[0024] (3) Finishing: send the withered leaves into the green-killing machine for finishing, the temperature for finishing is 200°C, after 100s of green-fixing, the withered leaves are cooled and sent to the microwave killing machine, the microwave power is adjusted to 15w / g, and the temperature is 100°C. The greening time is 80s, and the greening leaves with a moisture content of 50% are obtained;

[0025] (4) Ribbon shaping: send green leaves into the milling machine, rotate at a speed of 180 revolutions per minute, put the sizing stick into it, and after 1min, ta...

Embodiment 2

[0029] A processing method for white tea, comprising the following steps:

[0030] (1) plucking: pluck the fresh leaves of one bud and two leaves from the large-leaf species clone fine-bred tea tree;

[0031] (2) Withering: the fresh leaves of the tea tree are evenly spread on the withering tank with a thickness of 2 cm, placed at room temperature for 12 hours, and the withered leaves with a moisture content of 62% are obtained;

[0032] (3) Finishing: send the withered leaves into the green-killing machine for finishing, the temperature for finishing is 220°C, and after 200s, cool the withered leaves and send them to the microwave killing machine, adjust the microwave power to 25w / g, and the temperature to 120°C, The greening time is 100s, and the greening leaves with a moisture content of 45% are obtained;

[0033] (4) stencil shaping: send green leaves into the slitting machine, rotate at a speed of 200 revolutions per minute, put the sizing stick into it, and after 2min, ...

Embodiment 3

[0037] A processing method for white tea, comprising the following steps:

[0038] (1) Picking: Pick the fresh leaves of one bud and one leaf from the tea tree of large-leaf species clone;

[0039] (2) Withering: the tea tree fresh leaves are evenly spread on the withering tank with a thickness of 2 cm, placed at room temperature for 11 hours, and the withered leaves with a moisture content of 63% are obtained;

[0040] (3) Finishing: send the withered leaves into the green-killing machine for finishing, the temperature for finishing is 210°C, and after 150s of killing, cool the withered leaves and send them to the microwave killing machine, adjust the microwave power to 20w / g, and the temperature to 110°C, The greening time is 90s, and the greening leaves with a moisture content of 48% are obtained;

[0041] (4) Slimming and shaping: send green leaves into the slitting machine, rotate at a speed of 190 revolutions per minute, put the sizing stick into it, and after 1.5min, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com