Antibacterial film, preparing method and antibacterial repairing dressing

An antibacterial film and raw material technology, applied in the field of medicine, can solve the problems of iodine difficulty, slow repair of damaged tissue, unstable antibacterial properties, etc., and achieve the effect of safe and convenient clinical use and repair of damaged tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

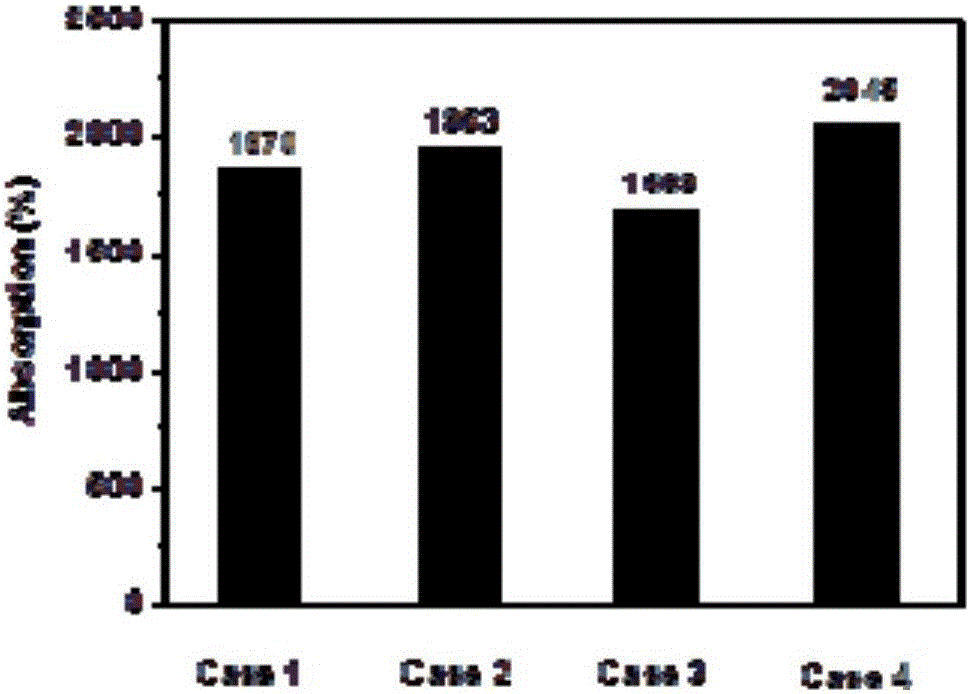

Embodiment 1

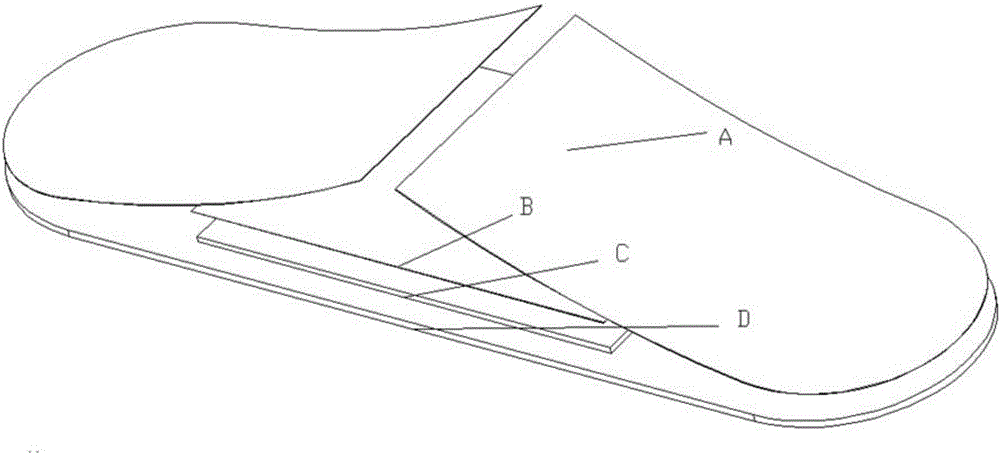

[0032] Embodiment 1 A kind of antibacterial repair dressing

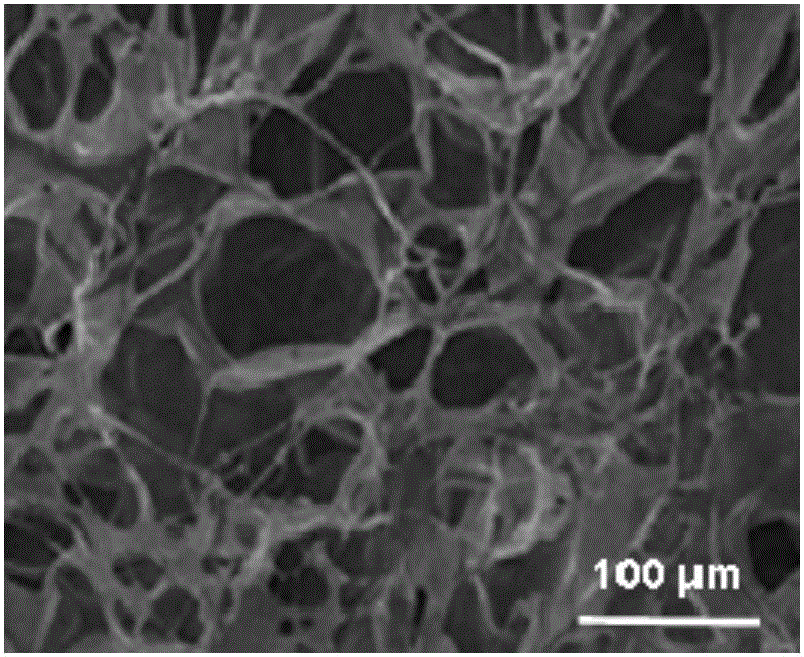

[0033] 1) Add 5% of gelatin into the reactor, introduce 70% of deionized water, adjust the temperature to 30°C-60°C until completely dissolved, add 10% of the medical polymer material into the above reactor, stir until dissolved, Add 0.2% glycerin to the above reactor, add 0.6% citric acid to the above reactor, stir for 5 minutes, add shell iodine complex 10%, stir for 45 minutes, transfer to a mold for molding, and demould to make a porous antibacterial membrane.

[0034] 2) Punch the prepared porous antibacterial film and sponge to a thickness of about 20mm by a flat hot press, stick it on the adhesive plaster, cover it with an anti-adhesive film, seal it and pack it, and sterilize it with r-rays.

Embodiment 2

[0035] Embodiment 2 A kind of antibacterial repair dressing

[0036] 1) Add 10% of gelatin into the reactor, import 70% of deionized water, adjust the temperature to 30°C-60°C until completely dissolved, add 15% of the medical polymer material into the above reactor, stir until dissolved, Add 0.2% glycerin to the above reactor, add 0.6% citric acid to the above reactor, stir for 5 minutes, add shell iodine complex 15%, stir for 50 minutes, transfer to a mold for molding, and release the porous antibacterial membrane.

[0037] 2) Punch the prepared porous antibacterial film and sponge to a thickness of about 20mm by a flat hot press, stick it on the adhesive plaster, cover it with an anti-adhesive film, seal it and pack it, and sterilize it with r-rays.

Embodiment 3

[0038] Embodiment 3 A kind of antibacterial repair dressing

[0039] 1) Add 5% of gelatin into the reactor, introduce 70% of deionized water, adjust the temperature to 30°C-60°C until completely dissolved, add 10% of the medical polymer material into the above reactor, stir until dissolved, Add 0.2% glycerin to the above reactor, add 0.6% citric acid to the above reactor, stir for 5 minutes, add shell iodine complex 5%, stir for 40 minutes, transfer to a mold for molding, and release the porous antibacterial membrane.

[0040] 2) Punch the prepared porous antibacterial film and sponge to a thickness of about 20mm by a flat hot press, stick it on the adhesive plaster, cover it with an anti-adhesive film, seal it and pack it, and sterilize it with r-rays.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com