Bending plate type tire and manufacturing method thereof

A technology of tires and bent plates, applied to tire parts, tires, non-pneumatic tires, etc., can solve problems such as difficult discharge, large number of elastic supports, and uneven running of wheels, so as to reduce elastic lag energy loss and run Safety guarantee and effect of reducing fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

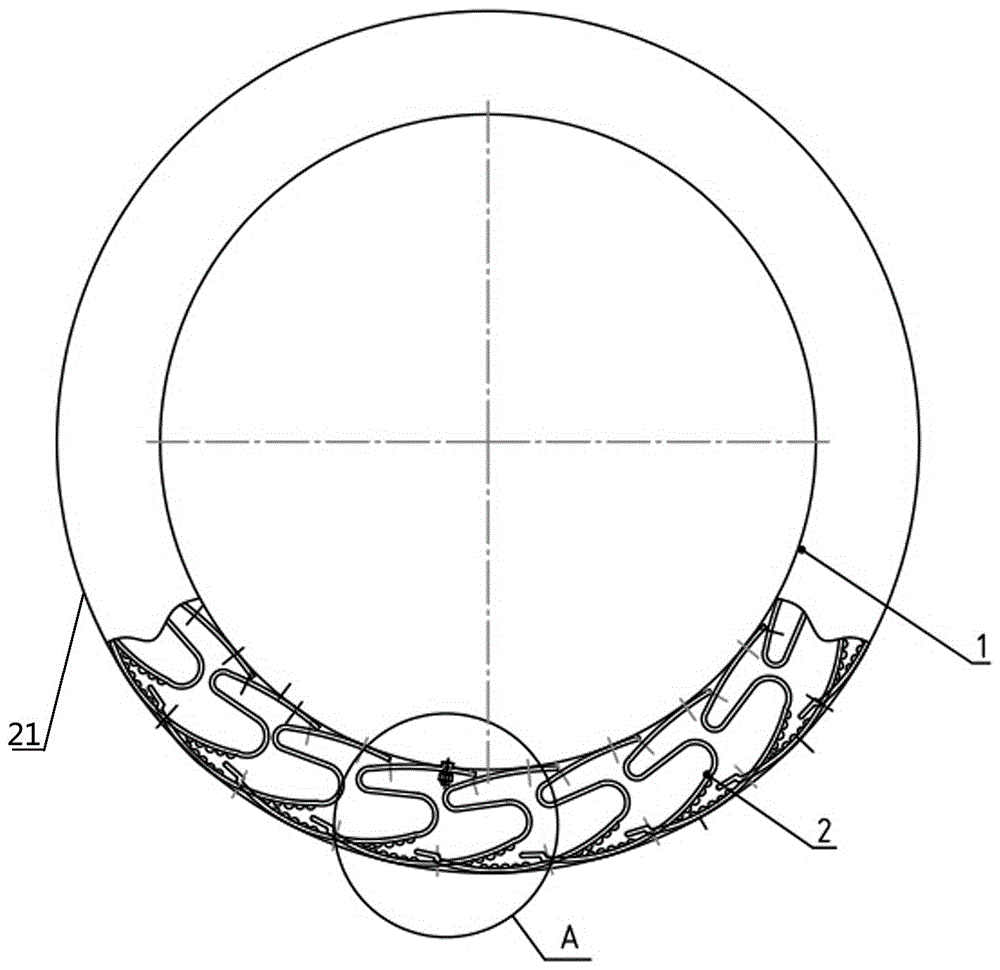

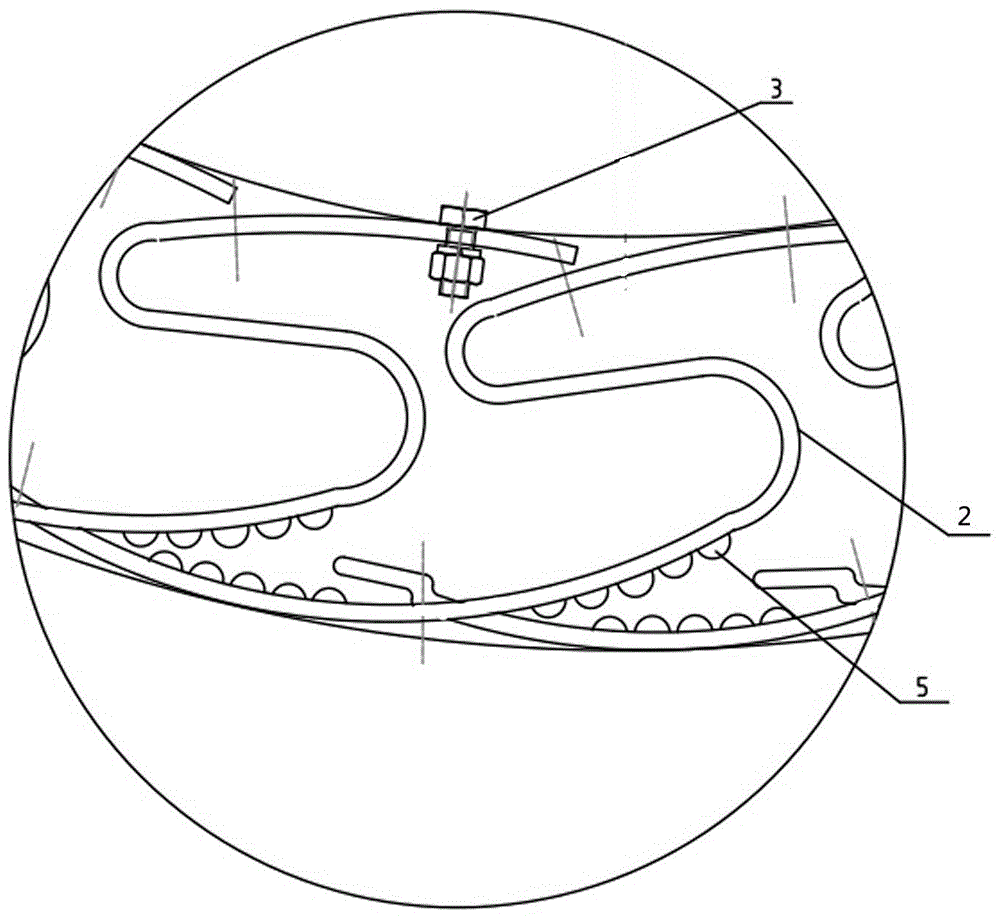

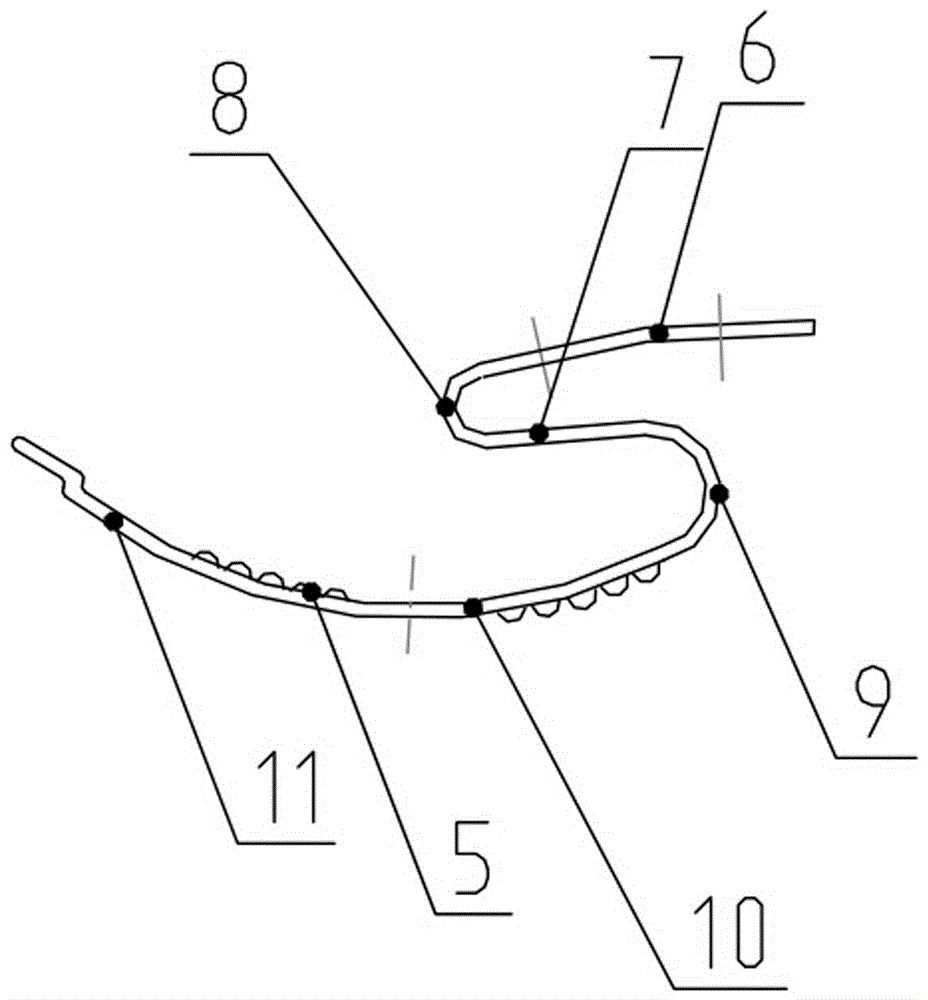

[0034] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Among them, the rim 1 is used as the installation and bearing base of the present invention, and one or several groups of evenly distributed radial through holes 20 are made on the circumferential working surface of the rim 1, so that several supports 2 can be connected to it through fasteners 3 .

[0035] As the carrying body of the present invention, there are one or several groups of supports 2 made of elastic plates with a continuous curved shape, and the groups of supports 2 form a support group through flexible connections. In the same group of support members 2, the shape, size, material properties and installation form of each support member 2 are consistent, so as to ensure the balance of the supporting elastic force of the wheel during operation, the tail section 11 of each support member 2 is connected to the Together, the mounting sections 6 of the respective supports 2 are mounted on the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com