Silicon coated release film

A release film, silicon release agent technology, applied in the direction of coating, can solve the problems of difficult coloring, low color fastness, low peeling force of the release agent layer, etc., to achieve easy coloring, high color fastness, The effect of improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

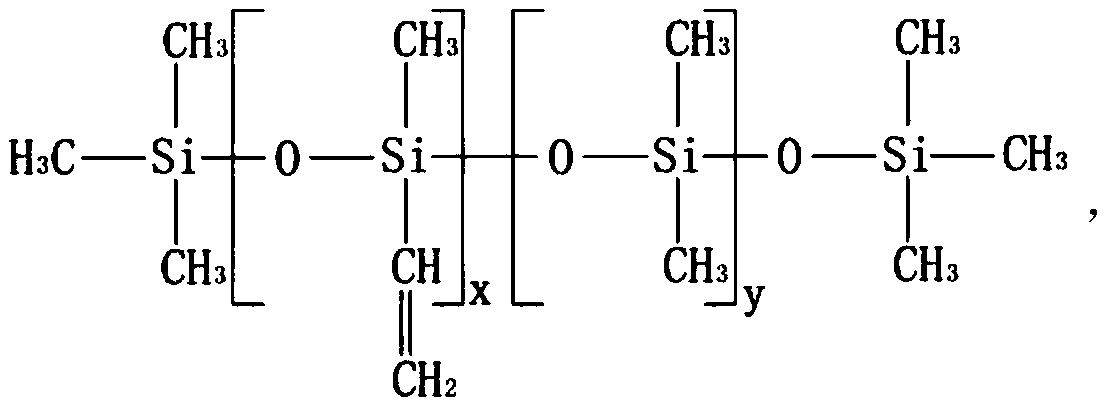

[0027] Embodiment 1A: The organosilicon release agent is prepared by the following method:

[0028] Step 1: Mix 25Kg of silicone prepolymer, 17Kg of acrylic acid, 8Kg of tert-butyl allyl formate, 6Kg of pseudolimonene and 60Kg of toluene, and add 5Kg of toluene and 0.9 The mixed solution of the dibenzoyl peroxide of Kg, insulation reaction 1 hour;

[0029] Step 2: Heat up to 88°C, add dropwise 25Kg of acrylic acid, 12Kg of tert-butyl allyl formate, 12Kg of pseudolimonene, 2.5Kg of E-44 epoxy resin, and 1.1Kg of dibenzoyl peroxide With the mixed solution of the toluene of 35Kg, the control rate of addition makes mixed solution dropwise in 3 hours,

[0030] Step 3: heat up to 97°C and keep warm for reaction;

[0031] Step 4: After the reaction is completed, remove the toluene in the reaction solution in Step 3 to obtain a crude product, place the crude product in an extraction device, extract with ethanol for 70 hours, and dry to obtain a silicone release agent.

[0032] Wher...

Embodiment 2A

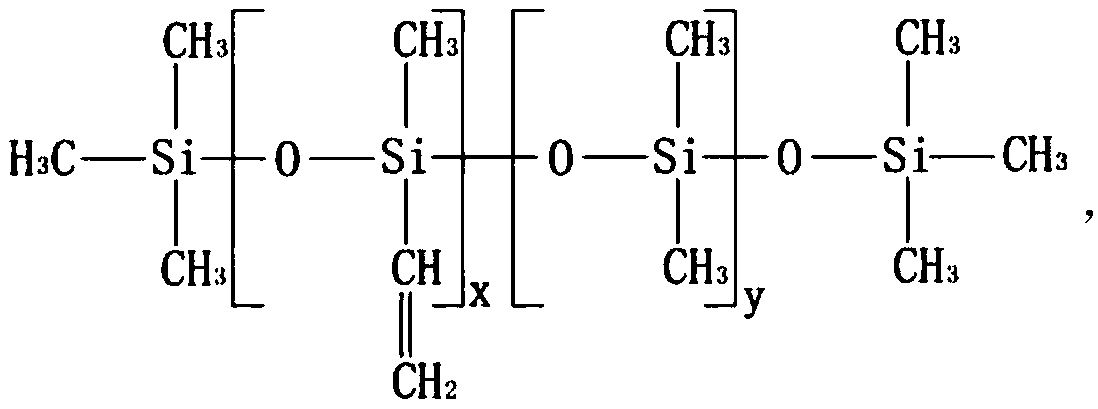

[0035] Embodiment 2A: The organosilicon release agent is prepared by the following method:

[0036] Step 1: Mix 27Kg of silicone prepolymer, 20Kg of acrylic acid, 6Kg of tert-butyl allyl formate, 5Kg of pseudolimonene and 70Kg of toluene, and add 8Kg of toluene and 0.8 The mixed solution of the dibenzoyl peroxide of Kg, insulation reaction 1.5 hours;

[0037] Step 2: heat up to 90°C, add dropwise 20Kg of acrylic acid, 15Kg of tert-butyl allyl formate, 10Kg of pseudolimonene, 3Kg of E-44 type epoxy resin, 1.2Kg of dibenzoyl peroxide and The mixed solution of the toluene of 30Kg, control rate of addition makes mixed solution dropwise in 3 hours,

[0038] Step 3: heat up to 95°C and keep warm for reaction;

[0039] Step 4: After the reaction is completed, remove the toluene in the reaction solution in Step 3 to obtain a crude product, place the crude product in an extraction device, extract with ethanol for 73 hours, and dry to obtain a silicone release agent.

[0040] Among t...

Embodiment 3A

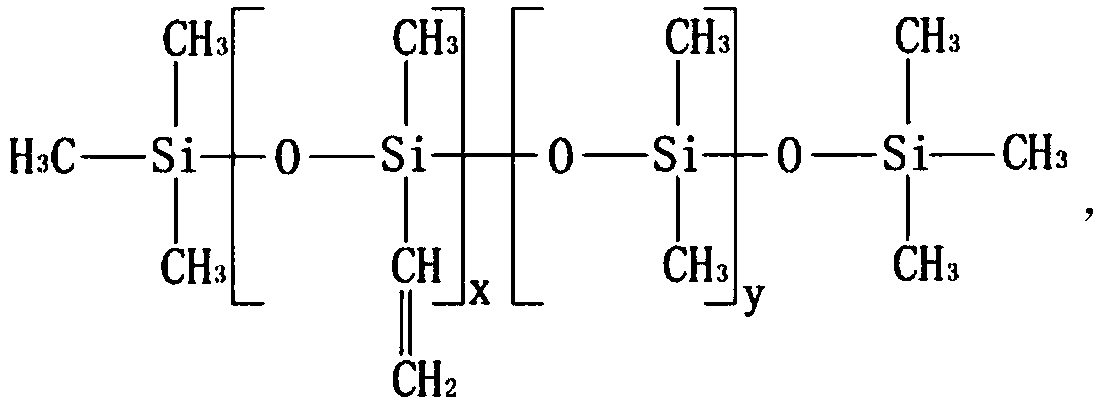

[0043] Embodiment 3A: The organosilicon release agent is prepared by the following method:

[0044] Step 1: Mix 30Kg of silicone prepolymer, 15Kg of acrylic acid, 5Kg of tert-butyl allyl formate, 7Kg of pseudolimonene and 65Kg of toluene, and add 6Kg of toluene and 1Kg of toluene at 80°C The mixed solution of dibenzoyl peroxide was incubated and reacted for 1.3 hours;

[0045] Step 2: Heat up to 92°C, add dropwise 22Kg of acrylic acid, 10Kg of tert-butyl allyl formate, 15Kg of pseudolimonene, 2Kg of E-44 epoxy resin, 1Kg of dibenzoyl peroxide and 40Kg The mixed solution of the toluene, control the rate of addition to make the mixed solution dropwise in 3 hours,

[0046] Step 3: heat up to 93°C and keep warm for reaction;

[0047] Step 4: After the reaction is completed, remove the toluene in the reaction solution in Step 3 to obtain a crude product, place the crude product in an extraction device, extract with ethanol for 75 hours, and dry to obtain a silicone release agent....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com