Water-based high-temperature-resistant air-drying coating and preparation method thereof

A high temperature-resistant, self-drying technology, applied in anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of poor salt spray resistance, low mechanical strength, long curing time, etc., to improve adhesion and increase heat resistance Sex, the effect of improving binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

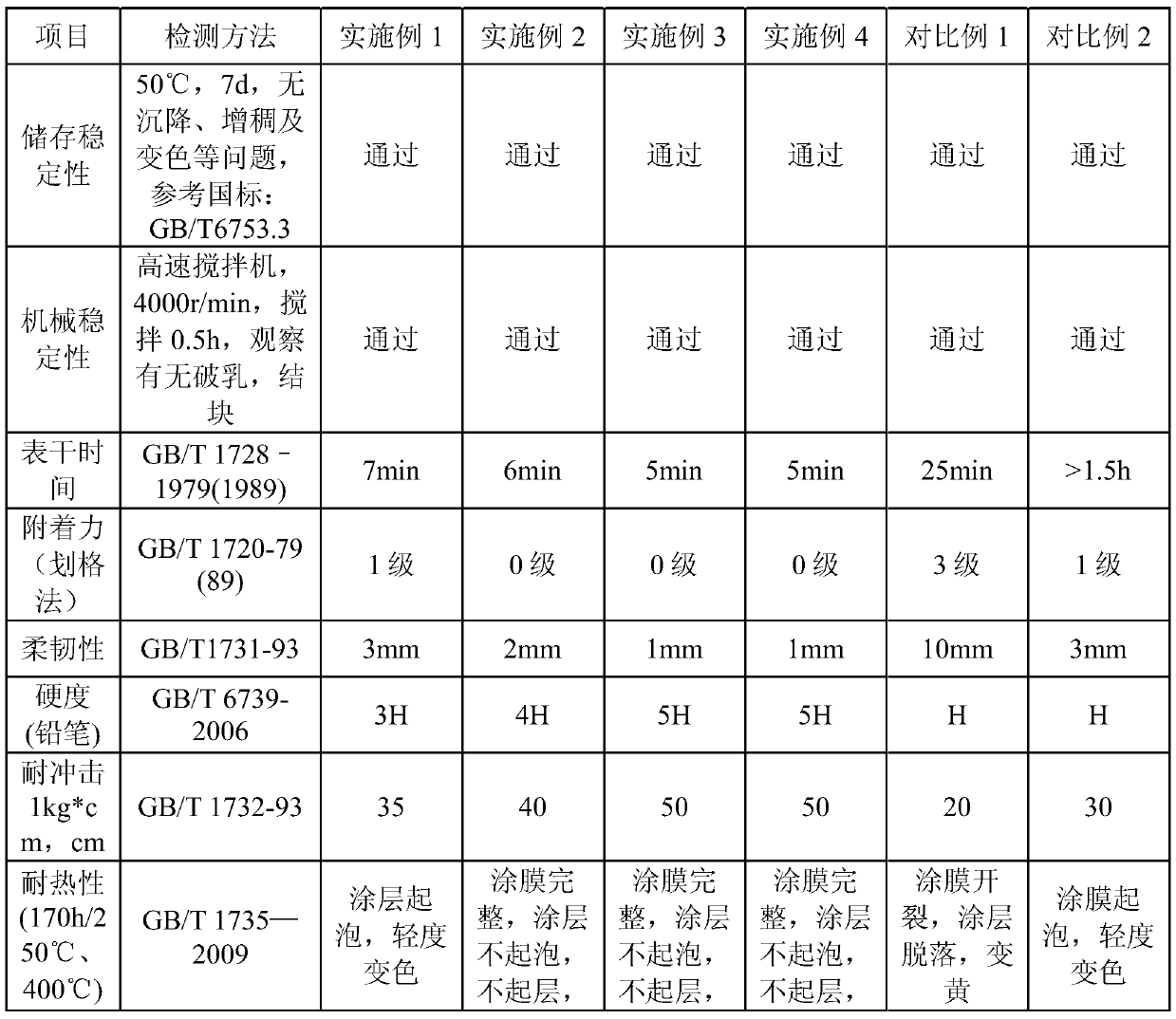

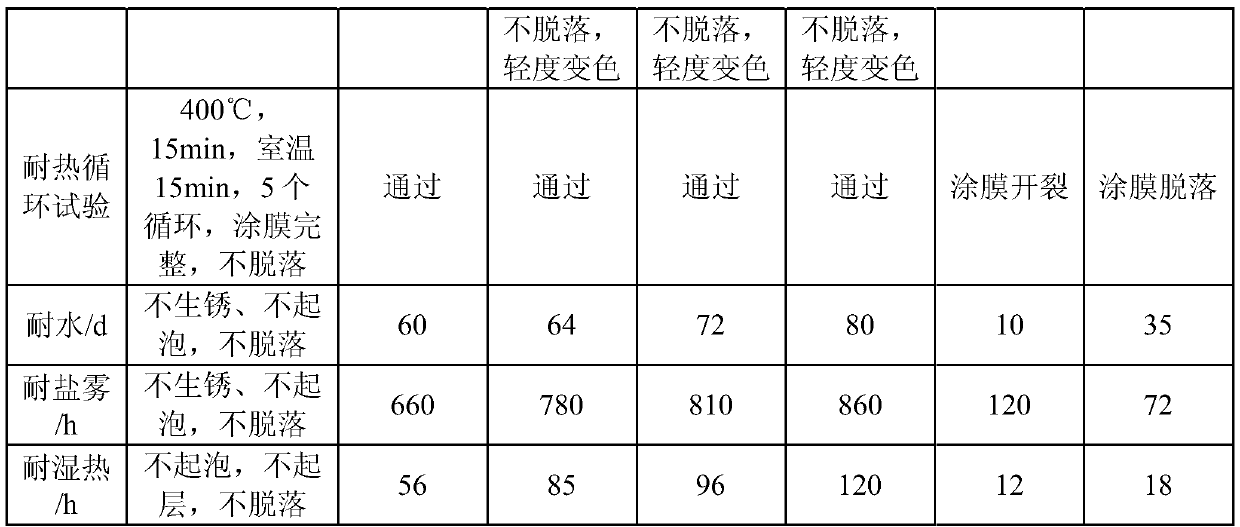

Examples

Embodiment 1

[0037] Water-based high-temperature-resistant self-drying coating, including the following components in parts by weight: 35 parts of water-based high-temperature-resistant resin, 0.5 parts of water-based silicone defoamer, 0.15 parts of amine neutralizer, 1.2 parts of substrate wetting agent, and dispersant 6 parts, 4 parts of film-forming aid (propylene glycol methyl ether), 3 parts of adhesion promoter, 7 parts of water-based high temperature resistant aluminum silver paste, 25 parts of distilled water I, 2 parts of thickener, and 2 parts of distilled water II.

[0038] The preparation method of the water-based high temperature resistant self-drying coating, the specific preparation steps are as follows:

[0039] (1) Add 35 parts of water-based high-temperature-resistant resin into the reaction tank, start stirring, control the temperature in the reaction tank to ≤40°C, control the speed of 800rpm / min, add 0.5 parts of water-based silicone defoamer, and amine neutralization ...

Embodiment 2

[0043] Water-based high-temperature-resistant self-drying coating, including the following components in parts by weight: 50 parts of water-based high-temperature-resistant resin, 0.6 parts of water-based silicone defoamer, 0.2 parts of amine neutralizer, 1.2 parts of substrate wetting agent, and dispersant 6 parts, 4 parts of film-forming aid (propylene glycol methyl ether), 3 parts of adhesion promoter, 8 parts of water-based high temperature resistant aluminum silver paste, 20 parts of distilled water I, 2 parts of thickener, and 2 parts of distilled water II.

[0044] The preparation method of the water-based high temperature resistant self-drying coating, the specific preparation steps are as follows:

[0045] (1) Add 50 parts of water-based high temperature resistant resin into the reaction tank, start stirring, control the temperature in the reaction tank to ≤40°C, control the speed of 900rpm / min, add 0.6 parts of water-based silicone defoamer and amine neutralization in...

Embodiment 3

[0049] Water-based high-temperature-resistant self-drying coating, including the following components in parts by weight: 60 parts of water-based high-temperature-resistant resin, 0.7 parts of water-based silicone defoamer, 0.3 parts of amine neutralizer, 1.5 parts of substrate wetting agent, and dispersant 7 parts, 5 parts of film-forming aid (propylene glycol methyl ether), 3 parts of adhesion promoter, 8 parts of water-based high temperature resistant aluminum silver paste, 20 parts of distilled water I, 3 parts of thickener, and 3 parts of distilled water II.

[0050] The preparation method of the water-based high temperature resistant self-drying coating, the specific preparation steps are as follows:

[0051] (1) Add 60 parts of water-based high-temperature-resistant resin into the reaction tank, start stirring, control the temperature in the reaction tank to ≤40°C, control the speed of 1000rpm / min, and add 0.7 parts of water-based silicone defoamer and amine neutralizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com