Full-automatic battery stack dismounting and conveying system for joining storage with production

A conveying system, fully automated technology, applied in the direction of conveyors, conveyor objects, object destacking, etc., can solve the problems of low production efficiency, small storage volume, poor working space environment, etc., to achieve automatic conveying and stable equipment Reliable, highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

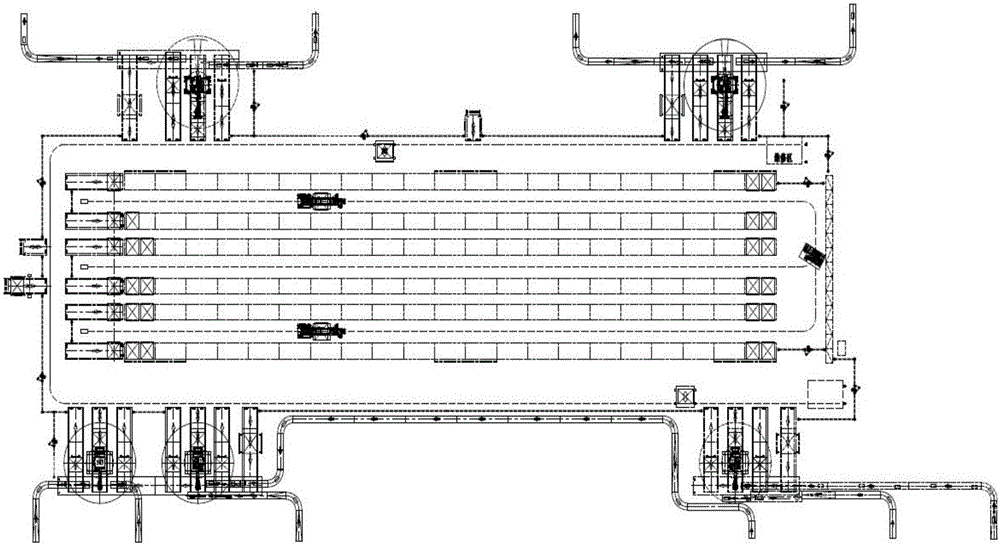

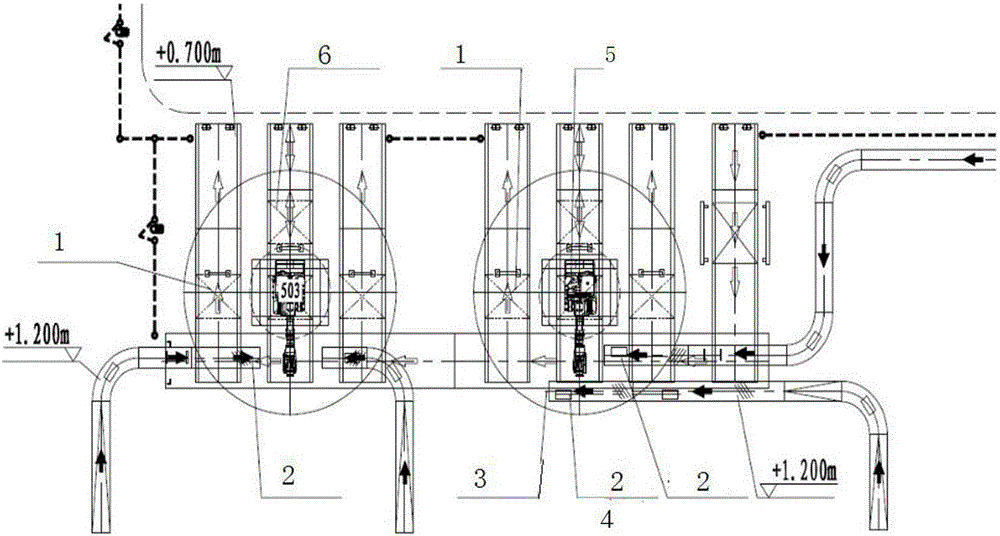

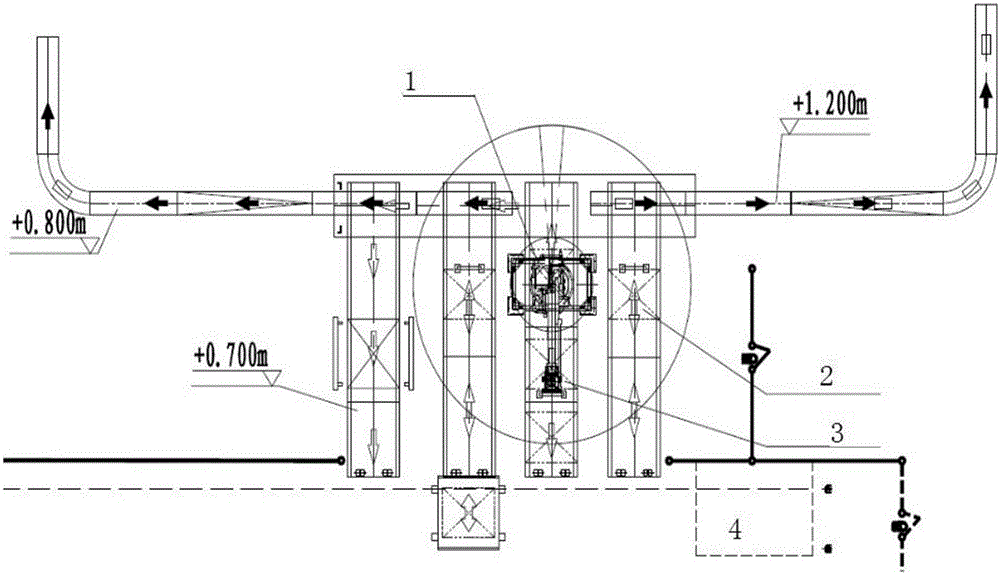

[0031] See Figure 1-Figure 4 , a fully automatic battery destacking and conveying system connecting between storage and production, the system includes a pallet conveying system, a battery palletizing system, a battery depalletizing system, an electronic control system, a computer management system, a barcode information collection system and other auxiliary equipment.

[0032] Pallet conveying system: including shuttle car system, chain conveyor, roller conveyor, pallet coder, swing conveyor, belt conveyor, shape inspection station and other equipment. State detection devices and other ancillary devices. Among them, the shuttle car system adopts the design of U-shaped track and one-track double-car shuttle car system. The working areas of the two shuttle cars are relatively fixed and dynamically adjusted, and there is no fixed working limit. The shuttle car system connects the storage units together. When a certain shuttle car breaks down, the other shuttle car can complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com