A kind of treatment method of burning polluted soil in cement kiln

A treatment method and technology for polluted soil, applied in cement production and other directions, can solve the problem of sludge industrial hazardous waste not being properly disposed of, and achieve the effects of reduced treatment costs, stable working conditions, and large treatment capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

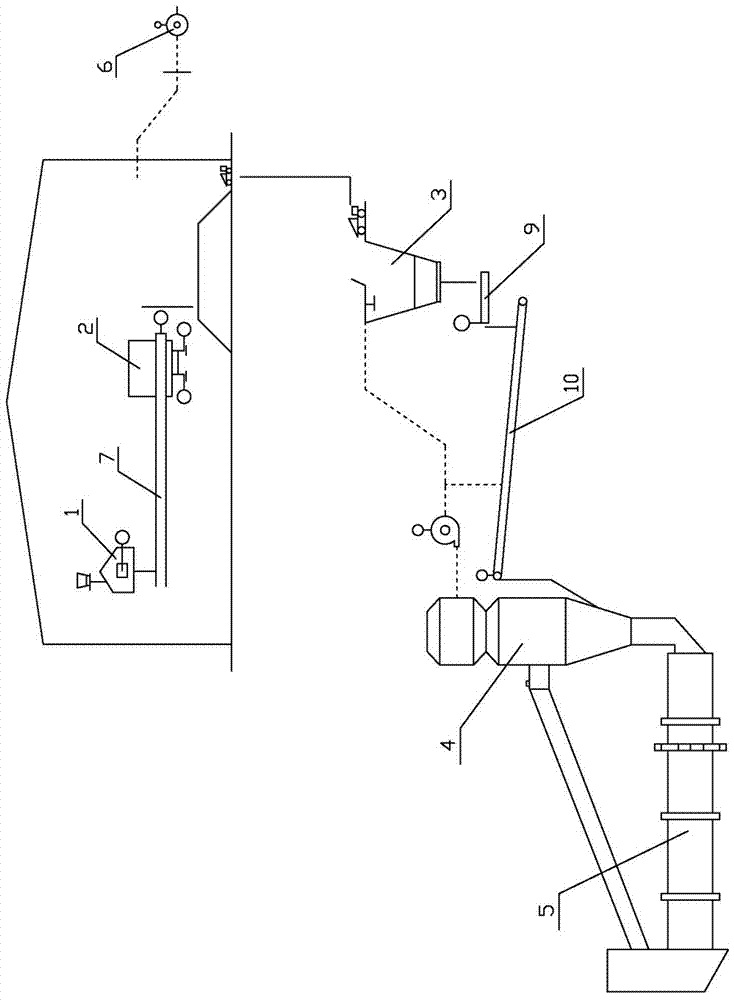

[0029] Such as figure 1 Shown, the processing method of a kind of cement kiln incineration polluted soil (water content about 10% sludge, particle size is not more than 200mm) of the present embodiment comprises the following steps:

[0030] A. Contaminated soil (sludge with a water content of about 10%, particle size ≯200mm) is transported by a special loading vehicle, first passed through the ground scale in the factory (using the original) for preliminary measurement, and then unloaded to the contaminated soil anti-blocking unloading bin;

[0031] B. The polluted soil in the unloading bin enters a multi-stage impact crusher 1 for crushing treatment. The crushing capacity of the crusher is 40t / h, and the crushing particle size is <5mm;

[0032] C. The broken polluted soil stacker 2 is transported to the finished product stacking shed for stacking and homogenizing storage;

[0033] D. A reclaimer is installed in the stacking shed, and the materials taken out are transported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com