Flexible perovskite thermal-control film and preparation method thereof

A thermal control thin film, perovskite technology, applied in the direction of manganate/permanganate, etc., to achieve the effect of easy large-scale production, large practical application value, and easy control of film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

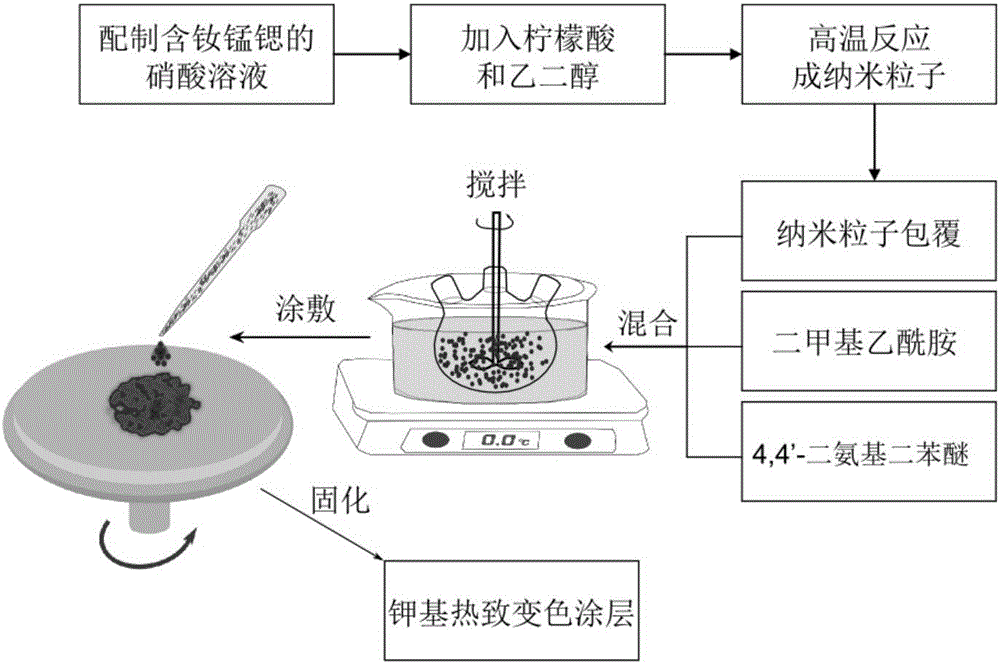

Method used

Image

Examples

Embodiment 1

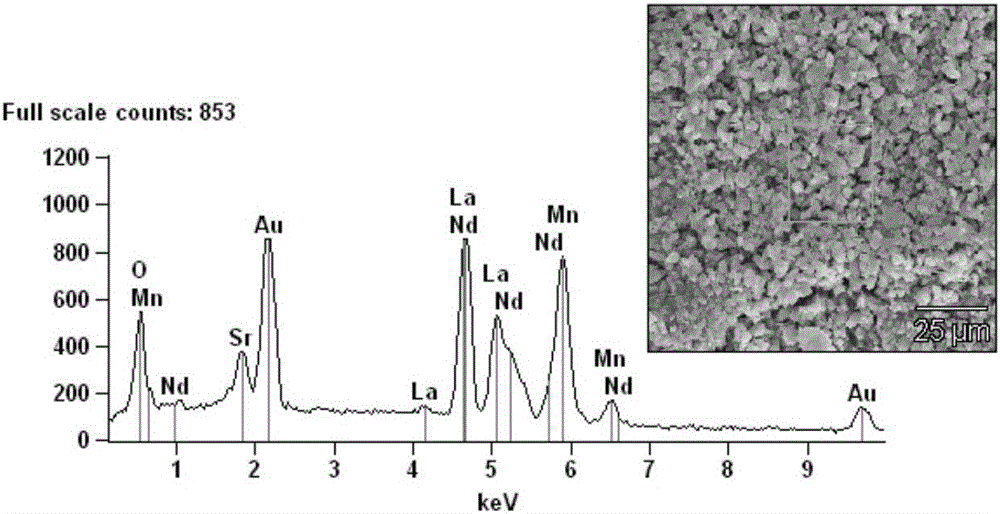

[0022] Step 1. Add 20 grams of nitric acid into 70 ml of deionized water, stir evenly at room temperature, then add 21.65 grams of lanthanum nitrate, 39.45 grams of neodymium nitrate, 12.7 grams of strontium nitrate, 71.58 grams of 50wt% manganese nitrate, and raise the temperature to 65 ℃ and stirred at a speed of 510r / min for 2.5 hours, added 0.48mol citric acid, and continued to stir for 3 hours to form a sol, added 11ml of ethylene glycol, continued to stir for 5 hours at the same speed and temperature, and stood at 65°C for 12 hours to obtain wet gel. Raise the wet gel placed in a high-temperature furnace to 420°C at a rate of 3.3°C / min and keep it warm for 3 hours. room temperature. Obtain the perovskite powder with a particle size of 150 nanometers through grinding or ball milling, figure 2 It shows that the main components of the perovskite powder in this embodiment are neodymium, strontium, manganese, and lanthanum.

[0023] Step 2. Add 10 grams of perovskite powd...

Embodiment 2

[0028] The first three steps of this embodiment are the same as in Embodiment 1, except for the fourth step.

[0029] The fourth step is: transfer the perovskite film sol obtained in the third step to a hard substrate with a temperature resistance of not less than 300° C., such as glass or silicon wafer. The cured film was obtained according to the stepwise temperature rise curing process described in step 4 in Example 1, and the cured film was peeled off from the hard substrate in ethanol or ethanol aqueous solution at 70°C and dried to obtain a flexible perovskite thermal control film. The emissivity at the temperature of 203K and 353K is 0.45 and 0.75 respectively, and the variation range of emissivity is 0.3.

Embodiment 3

[0031] The difference between this embodiment and Embodiment 1 lies in step one.

[0032] The first step is: 20 grams of nitric acid is added to 70 ml of deionized water, after stirring at room temperature, 34.64 grams of lanthanum nitrate, 26.3 grams of neodymium nitrate, 12.7 grams of strontium nitrate, 71.58 grams of 50wt% manganese nitrate are added successively, and the temperature is raised High to 65°C and stirred at 850r / min for 3 hours, added 0.48mol citric acid, and continued to stir for 4 hours to form a sol, added 15ml of ethylene glycol, continued to stir at the same speed and temperature for 5 hours, and stood at 65°C for 12 hour, a wet gel was obtained. Raise the wet gel placed in a high-temperature furnace to 550°C at a rate of 5°C / min and keep it warm for 3 hours. room temperature. The perovskite powder with a particle size of 400 nm is obtained by grinding or ball milling.

[0033] Others are the same as steps two to four in embodiment 1. The resulting fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com