Application of disperse dye composition

A technology of disperse dyes and compositions, which is applied in the application field of disperse dye compositions, and can solve problems such as lack, poor fastness, and poor lifting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

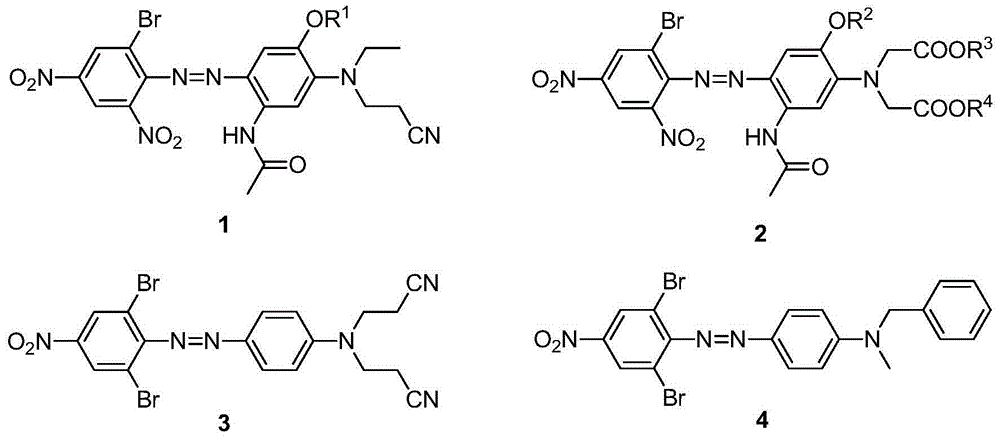

Examples

Embodiment 1

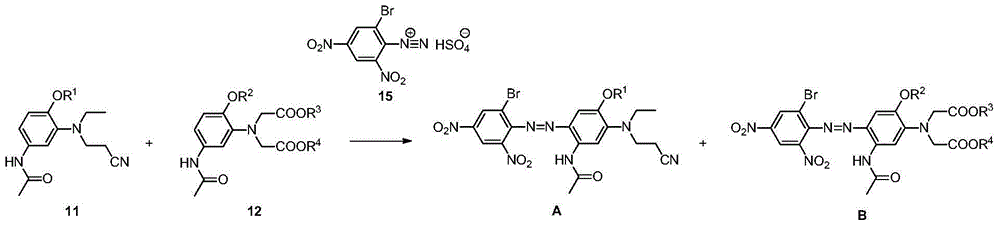

[0058] Mix 13.10 grams of 98% sulfuric acid and 16.4 grams of 40% nitrosyl sulfuric acid solution evenly, then slowly add 13.10 grams of 2,4-dinitro-6-bromoaniline at 25 to 28°C, and keep it here after adding The temperature range completes the diazotization reaction. 6.79 g of 2-methoxy-5-acetamido-N-ethyl-N-cyanoethylaniline, 8.42 g of 2-methoxy-5-acetamido-N,N-dimethoxycarbonylmethyl Aniline, 80 mL of water, 20 mL of acetic acid, and 0.2 g of sulfamic acid were mixed to form a mixed solution, which was coupled with the above-prepared diazo liquid at 0-5 ° C. After 3 hours of reaction, the temperature was raised to 65-70 ° C for 2 hours and filtered. , the product was washed with water until the pH value of the eluate was 6-7, and the mixed filter cake of dye compound 1-1 and compound 2-1 (the compound number was shown in Table 1) was obtained, the yield was 94.2%, and the total content of the combined product was analyzed by HPLC was 95.3%.

[0059] Table 1

[0060] ...

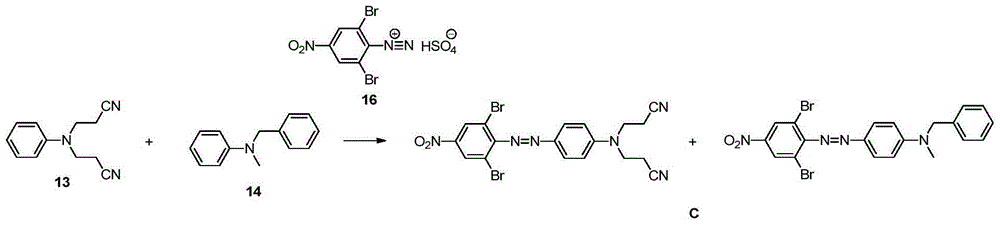

Embodiment 2

[0063] 14.8 g of 2,6-dibromo-4-nitroaniline was added to 12 g of 98% sulfuric acid at 25 to 35° C. and stirred for 2 hours. Keep at 20~28℃, slowly add 16.4 g of 40% nitrosylsulfuric acid solution dropwise, and then keep at this temperature for 2~4 hours to complete the diazotization reaction. 2 g of N,N-dicyanoethylaniline, 8.2 g of N-methyl-N-benzylaniline, 90 mL of water, 10 mL of sulfuric acid, and 0.2 g of sulfamic acid were mixed into a mixed solution, which was mixed with the prepared diazo liquid above. Coupling reaction occurs at 0-8°C, and the temperature is raised to 65-70°C for 2 hours after the reaction for 3 hours, filtered, and the product is washed with water until the pH value of the eluate is 6-7 to obtain a mixed filter cake of compounds 3 and 4. The yield was 94.4%, and the total content of the combination product was 94.3% by HPLC analysis.

Embodiment 3

[0065] After mixing 28.3 g of the mixture obtained in Example 1 and 21.7 g of the mixture obtained in Example 2 with 65 g of dispersant MF, 5 g of sodium lignosulfonate and 147 g of water, sand-milled and dispersed, and then spray-dried to obtain a disperse dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com