White-light fluorescent powder for LED and preparation method of fluorescent powder

A fluorescent powder, white light technology, applied in chemical instruments and methods, luminescent materials, sustainable buildings, etc., can solve the problems of high cost and doping more rare earth ions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

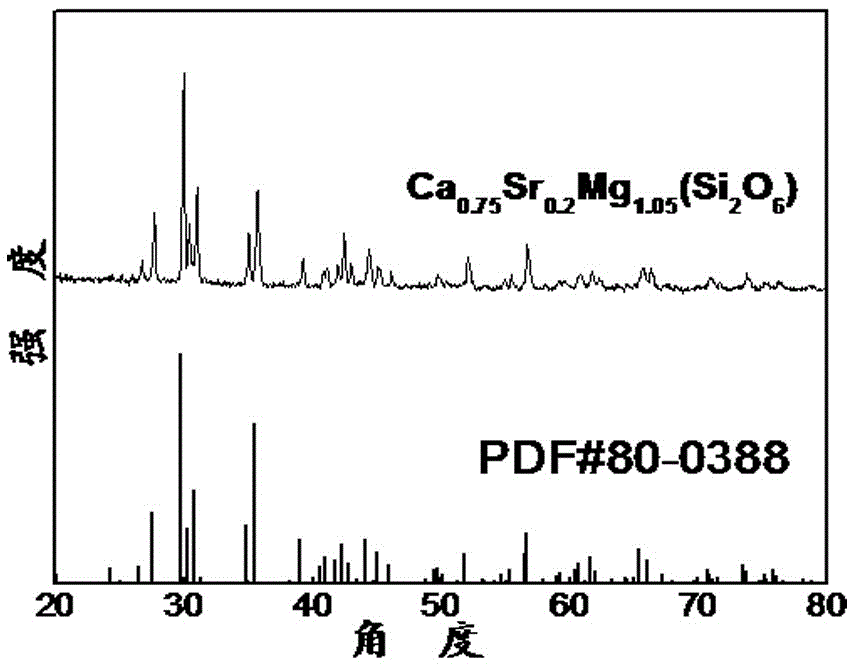

Embodiment 1

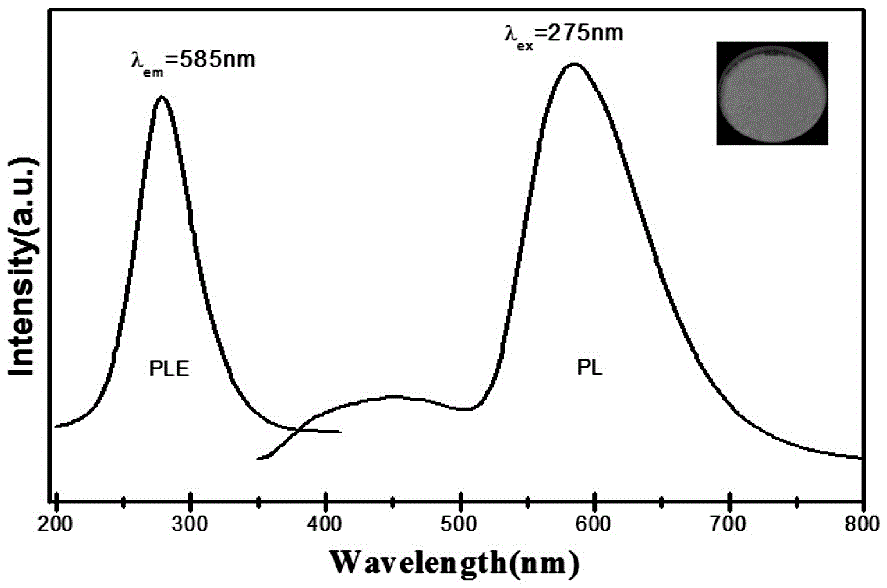

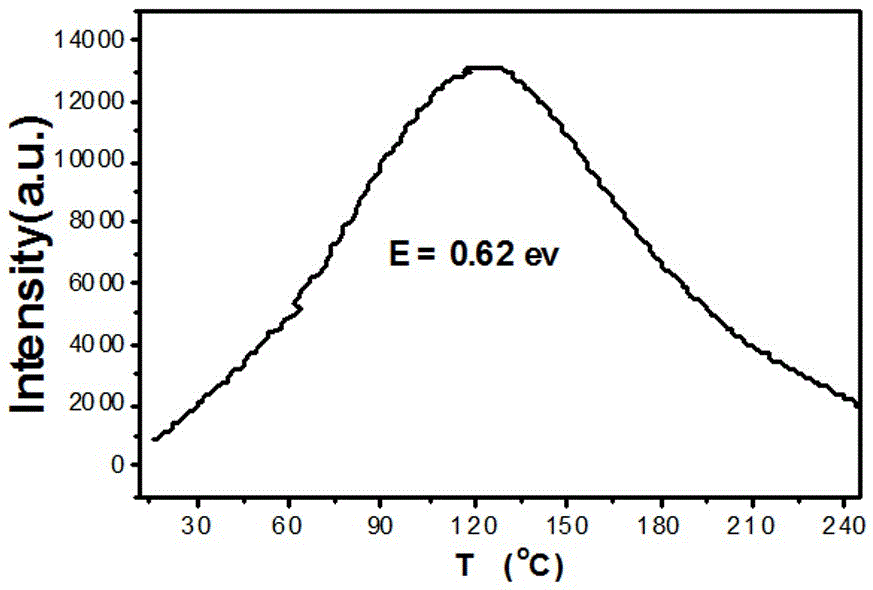

[0027] Weigh calcium carbonate (CaCO 3 ) 0.9759g, strontium carbonate (SrCO 3 ) 0.3838g, magnesium oxide (MgO) 0.5501g, silicon dioxide (SiO 2 ) 1.5621g, placed in an agate mortar and ground for 30 minutes and mixed evenly; the ground powder was placed in a small dry pot and buried in a carbon powder reducing atmosphere for roasting, and the heating rate was 8°C / min to 1300°C, sintered at this temperature for 6 hours, and cooled naturally to room temperature; the sample was taken out and ground, and the chemical formula was Ca 0.75 Sr 0.2 Mg 1.05 (Si 2 o 6 ) of the silicate matrix.

Embodiment 2

[0029] Weigh calcium carbonate (CaCO 3 ) 0.9368g, strontium carbonate (SrCO 3 ) 0.3838g, magnesium oxide (MgO) 0.5344g, silicon dioxide (SiO 2 ) 1.5621g, manganese carbonate (MnCO 3) 0.0299g, europium trioxide (Eu 2 o 3 ) 0.0686g, put it in an agate mortar and grind it for 30 minutes and mix it evenly; put the ground powder in a small dry pot and bury it in a carbon powder reducing atmosphere for roasting, and heat up to 1300°C, sintered at this temperature for 6 hours, and cooled naturally to room temperature; the sample was taken out and ground, and the chemical formula was Ca 0.72 Eu 0.03 Sr 0.2 Mg 1.03 mn 0.02 (Si 2 o 6 ) white light phosphor.

Embodiment 3

[0031] Weigh calcium carbonate (CaCO 3 ) 0.9499g, strontium carbonate (SrCO 3 ) 0.3838g, magnesium oxide (MgO) 0.5344g, silicon dioxide (SiO 2 ) 1.5621g, manganese carbonate (MnCO 3 ) 0.0448g, europium trioxide (Eu 2 o 3 ) 0.0457g, put it in an agate mortar and grind it for 20 minutes and mix it evenly; put the ground powder in a small dry pot and bury it in a carbon powder reducing atmosphere for roasting, and heat up at a heating rate of 10°C / min to 1300°C, sintered at this temperature for 6 hours, and cooled naturally to room temperature; the sample was taken out and ground, and the chemical formula was Ca 0.73 Eu 0.02 Sr 0.2 Mg 1.02 mn 0.03 (Si 2 o 6 ) white light phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com