A kind of fluorescent powder for warm white LED and preparation method thereof

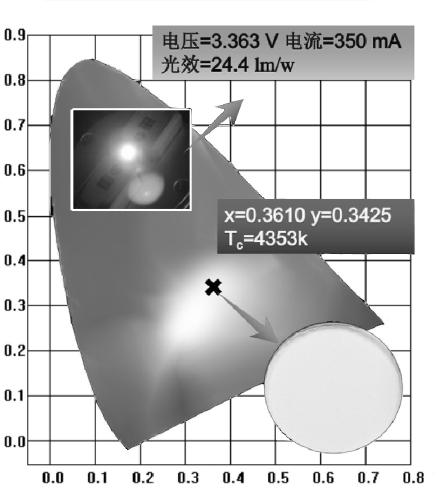

A phosphor, warm white light technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of reduced luminous efficiency, high cost, doping more rare earth ions, etc., and achieves short preparation time, high production efficiency, and luminescence. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

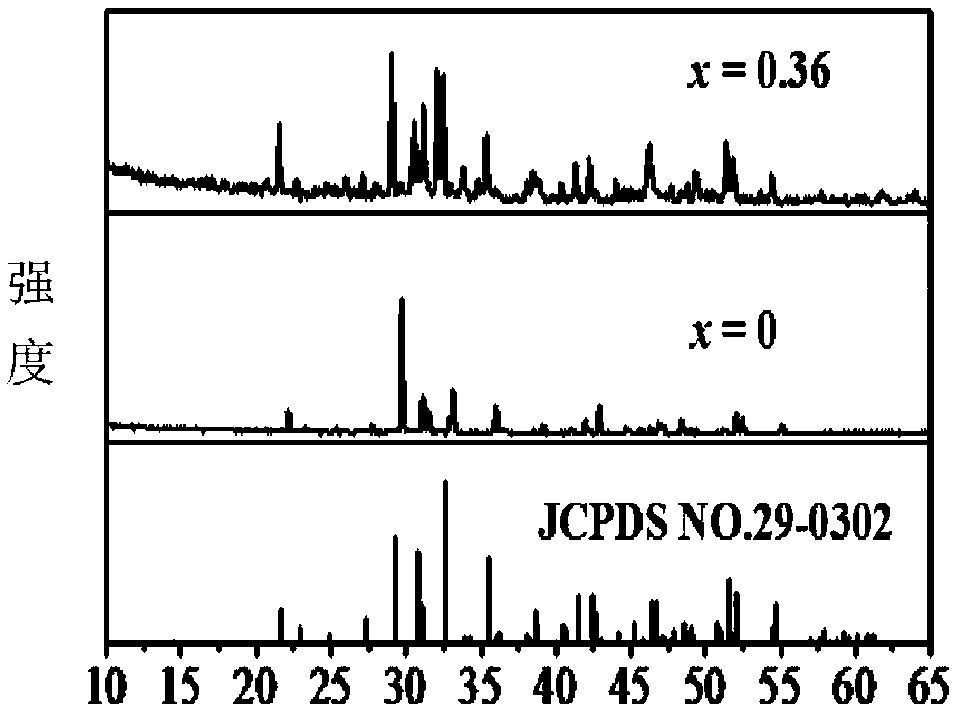

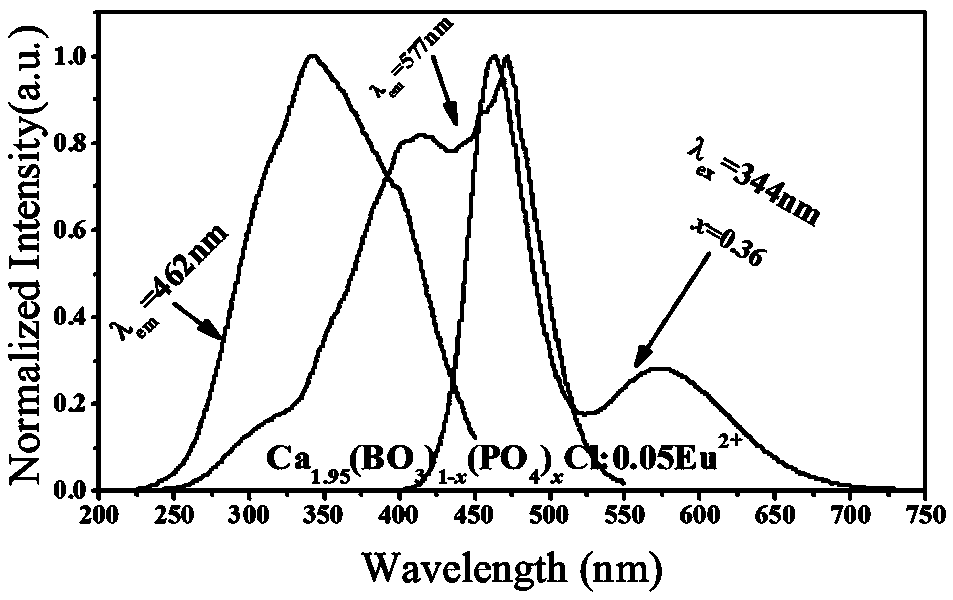

Embodiment 1

[0024] Weigh calcium carbonate (CaCO 3 ) 1.5736g, anhydrous calcium chloride (CaCl 2 ·5H 2 O) 0.6017g, boric acid (H 3 BO 3 )0.4505g europium trioxide (Eu 2 o 3 )0.0954g and ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 0.4489g, placed in an agate mortar and thoroughly ground for 30 minutes and mixed evenly; the ground powder was placed in a small dry pot and buried in a carbon powder reducing atmosphere for roasting, and the heating rate was 5 ° C / min to heat up to 940°C, sintered at this temperature for 4 hours, and naturally cooled to room temperature; the sample was taken out and ground, and the chemical formula was Ca 1.95 Eu 0.05 (BO 3 ) 0.64 (PO 4 ) 0.36 Cl's white phosphor.

Embodiment 2

[0026] Weigh calcium carbonate (CaCO 3 ) 1.5736g, anhydrous calcium chloride (CaCl 2 ·5H 2 O) 0.6017g, boric acid (H 3 BO 3 )0.4786g europium trioxide (Eu 2 o 3 )0.0954g and ammonium dihydrogen phosphate (NH 4 h 2 PO 4) 0.3990g, placed in an agate mortar and ground for 30 minutes and mixed evenly; the ground powder was placed in a small dry pot and buried in a carbon powder reducing atmosphere for roasting, and the heating rate was 5 ° C / min to heat up to 950°C, sintered at this temperature for 4 hours, and naturally cooled to room temperature; the sample was taken out and ground, and the chemical formula was Ca 1.95 Eu 0.05 (BO 3 ) 0.68 (PO 4 ) 0.32 Cl's white phosphor.

Embodiment 3

[0028] Weigh calcium carbonate (CaCO 3 ) 1.5736g, anhydrous calcium chloride (CaCl 2 ·5H 2 O) 0.6017g, boric acid (H 3 BO 3 )0.4646g europium trioxide (Eu 2 o 3 )0.0954g and ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 0.4240g, placed in an agate mortar and thoroughly ground for 30 minutes and mixed evenly; the ground powder was placed in a small dry pot and buried in a carbon powder reducing atmosphere for roasting, and the heating rate was 5 ° C / min to heat up to 1000°C, sintered at this temperature for 3 hours, and cooled naturally to room temperature; the sample was taken out and ground, and the chemical formula was Ca 1.95 Eu 0.05 (BO 3 ) 0.66 (PO 4 ) 0.34 Cl's white phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com