Tin-based Babbitt alloy and preparation method thereof

A technology of tin-based babbitt alloy and master alloy, which is applied in the field of tin-based babbitt alloy and its preparation, can solve problems such as the potential hazard of arsenic, and achieve the effects of increasing nucleation rate, avoiding segregation, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of tin-based babbitt alloy comprises each component of following percentage by weight: 11% antimony (Sb), 6% copper (Cu), 0.5% titanium (Ti), 0.5% nickel (Ni), balance is tin (Sn).

[0026] The preparation method of the above-mentioned tin-based babbitt alloy, the steps are: a. use a vacuum intermediate frequency furnace to make a master alloy, the master alloy includes 10% Ti by weight, 5% Ni by weight, and the rest being Cu B. with master alloy, a certain amount of pure Cu (calculated according to the Cu content in the above-mentioned alloy and the Cu content in the master alloy), a certain amount of pure Ni (according to the Ni content in the above-mentioned alloy and the Ni content in the master alloy) content), a certain amount of pure Sb (calculated according to the Sb content in the above alloy) and a certain amount of pure Sn (calculated according to the Sn content in the above alloy) are mixed and smelted as raw materials, and cast to obtain the required...

Embodiment 2

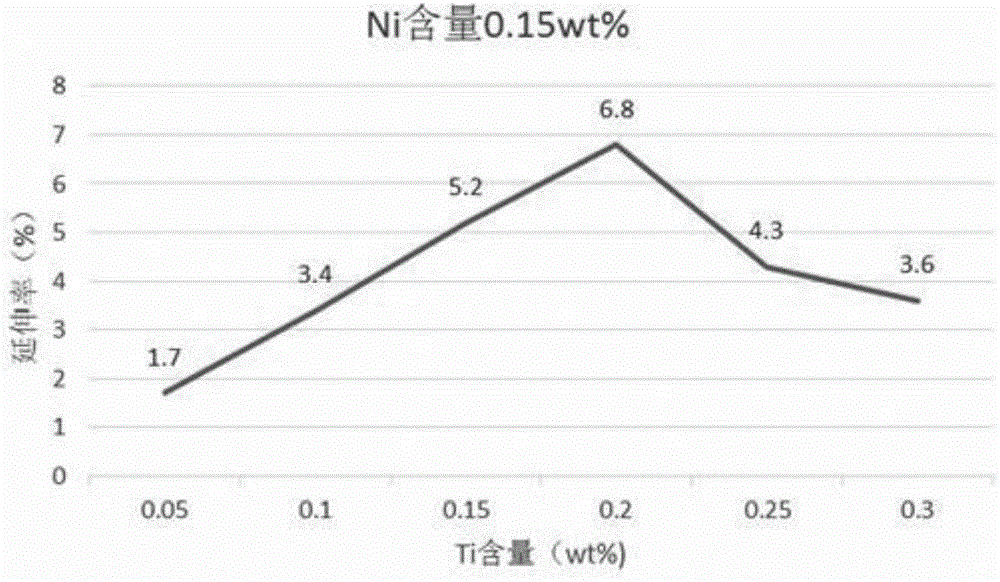

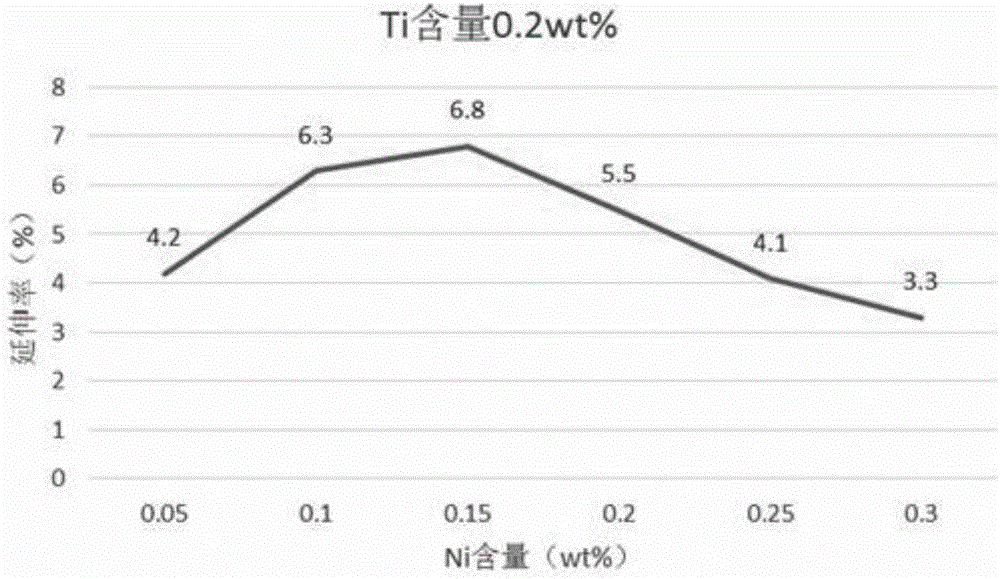

[0028] A tin-based babbitt alloy includes the following components in weight percentage: 11% of Sb, 6% of Cu, 0.2% of Ti and 0.15% of Ni, and the balance is Sn.

[0029] The preparation method of the above-mentioned tin-based babbitt alloy, the steps are: a. use a vacuum intermediate frequency furnace to make a master alloy, the master alloy includes 10% Ti by weight, 5% Ni by weight, and the rest being Cu B. with master alloy, a certain amount of pure Cu (calculated according to the Cu content in the above-mentioned alloy and the Cu content in the master alloy), a certain amount of pure Ni (according to the Ni content in the above-mentioned alloy and the Ni content in the master alloy) content), a certain amount of pure Sb (calculated according to the Sb content in the above alloy) and a certain amount of pure Sn (calculated according to the Sn content in the above alloy) are mixed and smelted as raw materials, and cast to obtain the required tin base Babbitt.

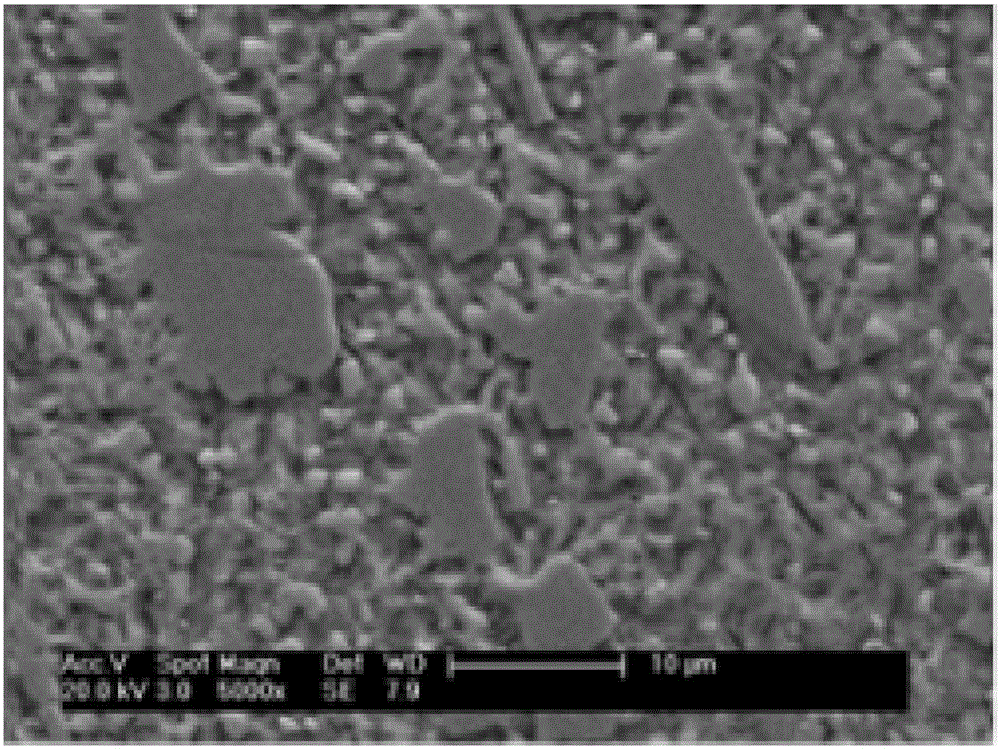

[0030] ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com