Electrolysis device and electrolysis method for preparing hypochlorous acid

An electrolysis device and electrolysis method technology, applied in the electrolysis process, electrolysis components, electrodes and other directions, can solve the problems of difficult control of the electrolysis process, large equipment volume, uncontrollable pH value, etc., and achieve convenient use, safe use and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0028] The present invention is an electrolysis device for producing hypochlorous acid, by which chlorine gas for producing hypochlorous acid is generated.

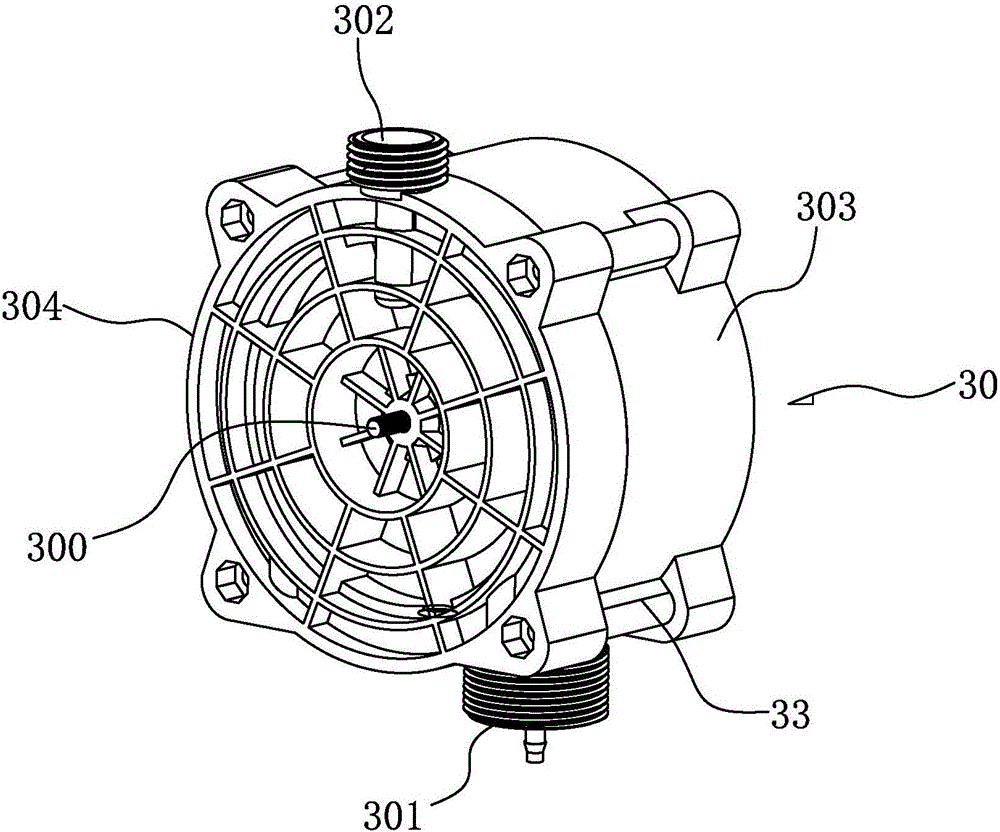

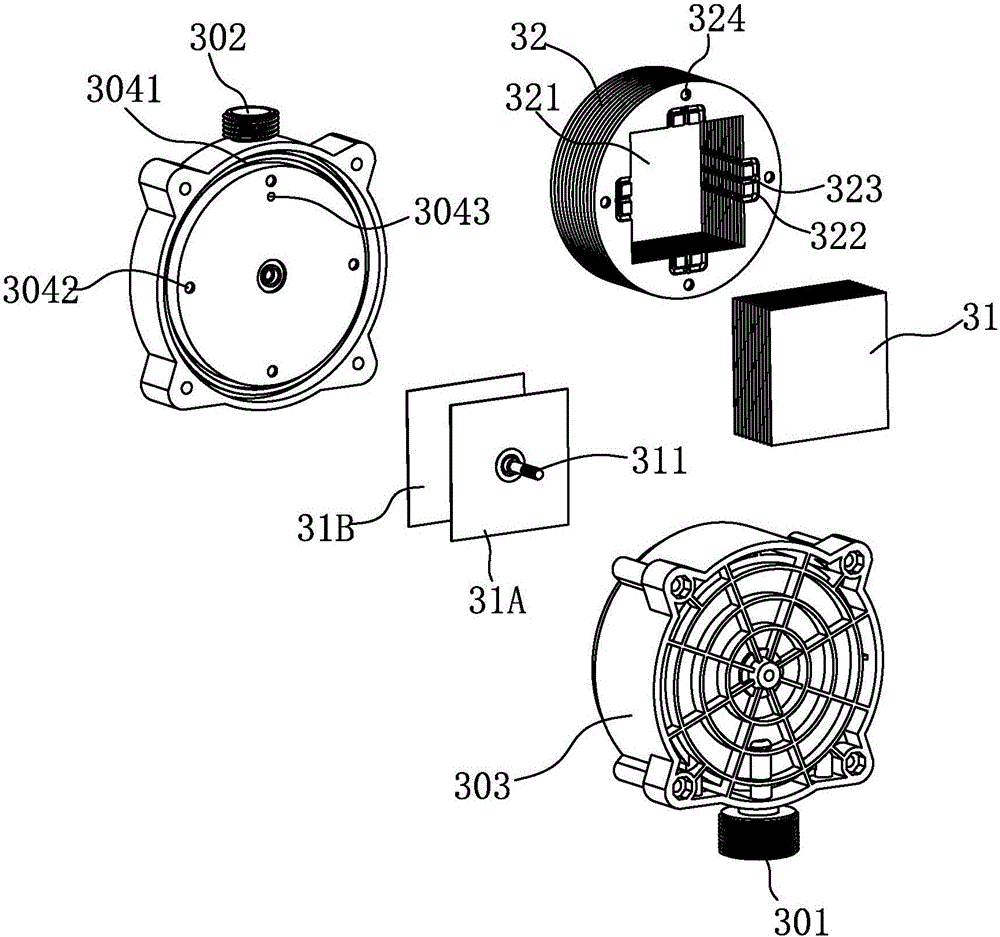

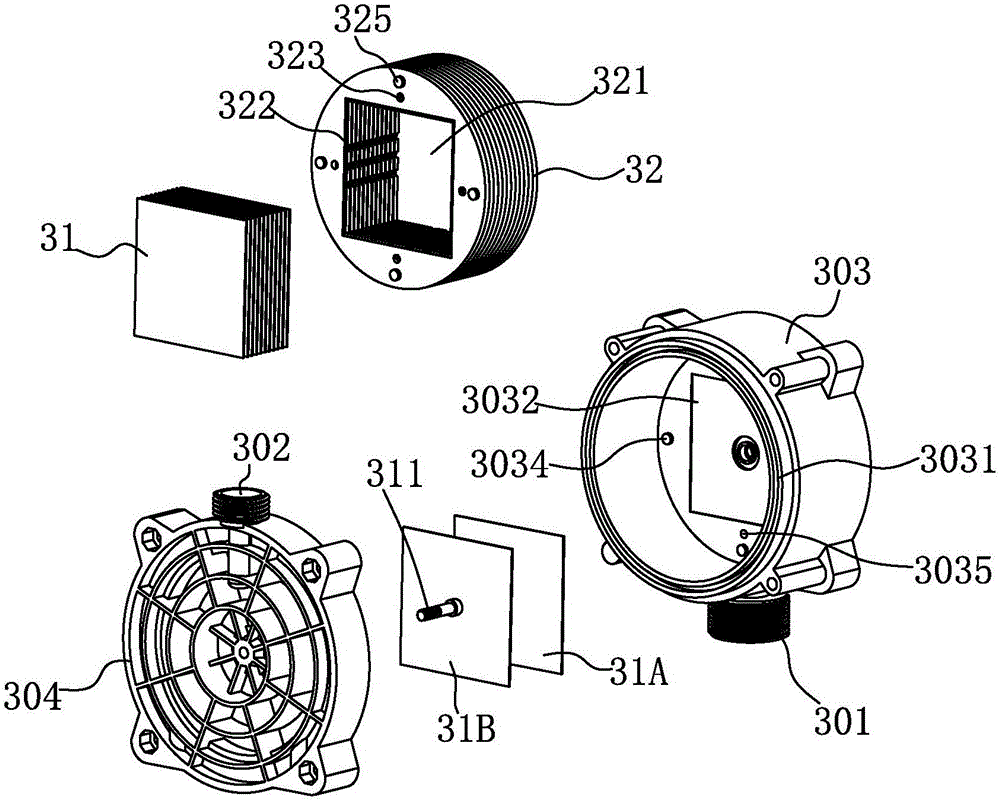

[0029] See Figure 1-5 As shown, the electrolysis device 3 is a box body 30 provided with an acid inlet 301 and a gas outlet 302 , and an electrode piece 31 is arranged inside the box body 30 . The electrolysis device 3 includes: a box body 30 provided with an acid inlet 301 and an air outlet 302, an electrode sheet group located in the box body 30, the electrode sheet group is arranged at intervals by a plurality of electrode sheets 31, wherein the electrode sheet group Electrode conductive ends 311 leading out of the box body 30 are fixed on the middle electrode sheets 31A and 31B.

[0030] The box body 30 includes: a front box body 303 and a rear box body 304 fastened by fixing screws, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com