Textile subjected to water repellency treatment and production method thereof

A production method and technology for textiles, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of water repellency that cannot reach the performance of fluorine-containing products, human harm, etc., and achieve high washing durability, high safety, The effect of low wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

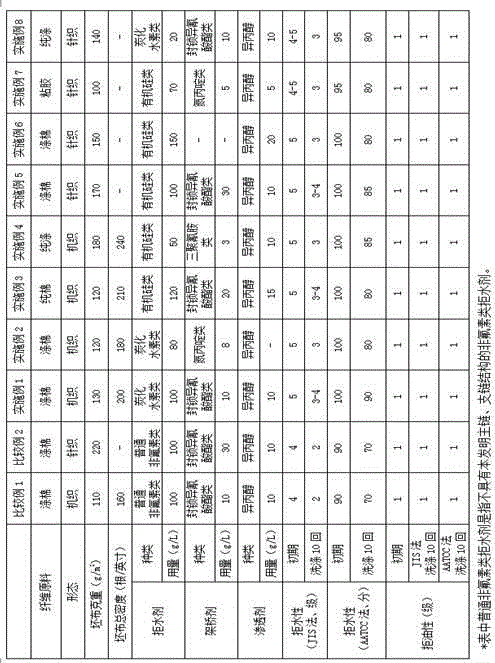

Examples

Embodiment 1

[0051] Pair of polyester-cotton woven gray fabric (polyester 65%, cotton 35%; weight 130g / m 2 , with a total density of 200 strands / inch), and then perform water-repellent finishing in the following processing solution to obtain the textile of the present invention. The performance test results are shown in the summary table.

[0052] The processing fluid consists of the following components:

[0053] Water repellent agent A100g / L

[0054] Bridging agent A10g / L

[0055] Penetrant 10g / L

[0056] The rest is water.

[0057] The specific processing conditions for water-repellent finishing are as follows: one dipping and one rolling process, then heat treatment at a temperature of 130°C for 2 minutes, and finally finishing at a temperature of 170°C for 60 seconds.

Embodiment 2

[0059] Pair of polyester-cotton woven gray fabric (polyester 35%, cotton 65%; weight 120g / m 2 , with a total density of 180 strands / inch), after dyeing, water-repellent finishing is carried out in the following processing liquid to obtain the textiles of the present invention, and the performance test results are shown in the general table.

[0060] The processing fluid consists of the following components:

[0061] Water repellent B80g / L

[0062] Bridging agent B8g / L

[0063] The rest is water.

[0064] The specific processing conditions for water-repellent finishing are as follows: one dipping and one rolling process, then heat treatment at 120°C for 3 minutes, and finally finishing at 170°C for 60 seconds.

Embodiment 3

[0066] For pure cotton woven gray fabric (gram weight is 120g / m 2 , with a total density of 210 strands / inch), and then perform water-repellent finishing in the following processing liquid to obtain the textile of the present invention. The performance test results are shown in the general table.

[0067] The processing fluid consists of the following components:

[0068] Water repellent D120g / L

[0069] Bridging agent A20g / L

[0070] Penetrant 15g / L

[0071] The rest is water.

[0072] The specific processing conditions for water-repellent finishing are as follows: one dipping and one rolling process, then heat treatment at a temperature of 110°C for 5 minutes, and finally finishing at a temperature of 160°C for 60 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com