Process for preparing sealing material with carbon fibers by Hatschek Process

A sealing material and carbon fiber technology, which is applied in fiber raw material processing, synthetic cellulose/non-cellulose material pulp/paper, inorganic compound addition, etc., can solve problems such as poor carbon fiber binding ability, and achieve the effect of solving poor binding ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

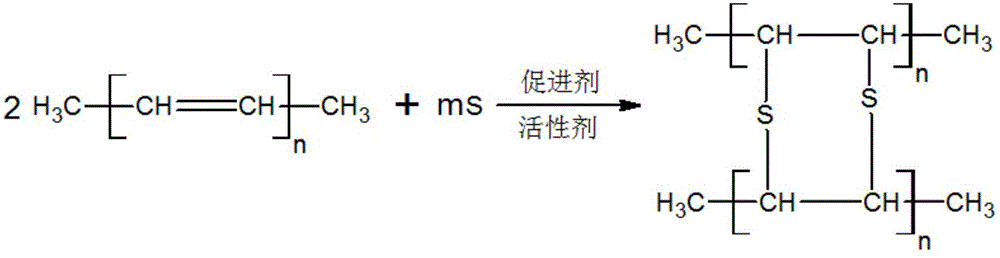

Method used

Image

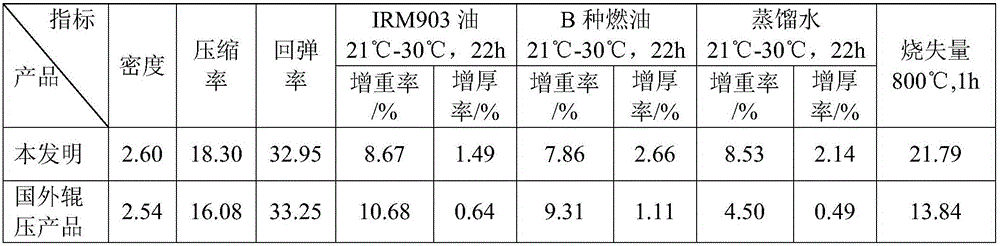

Examples

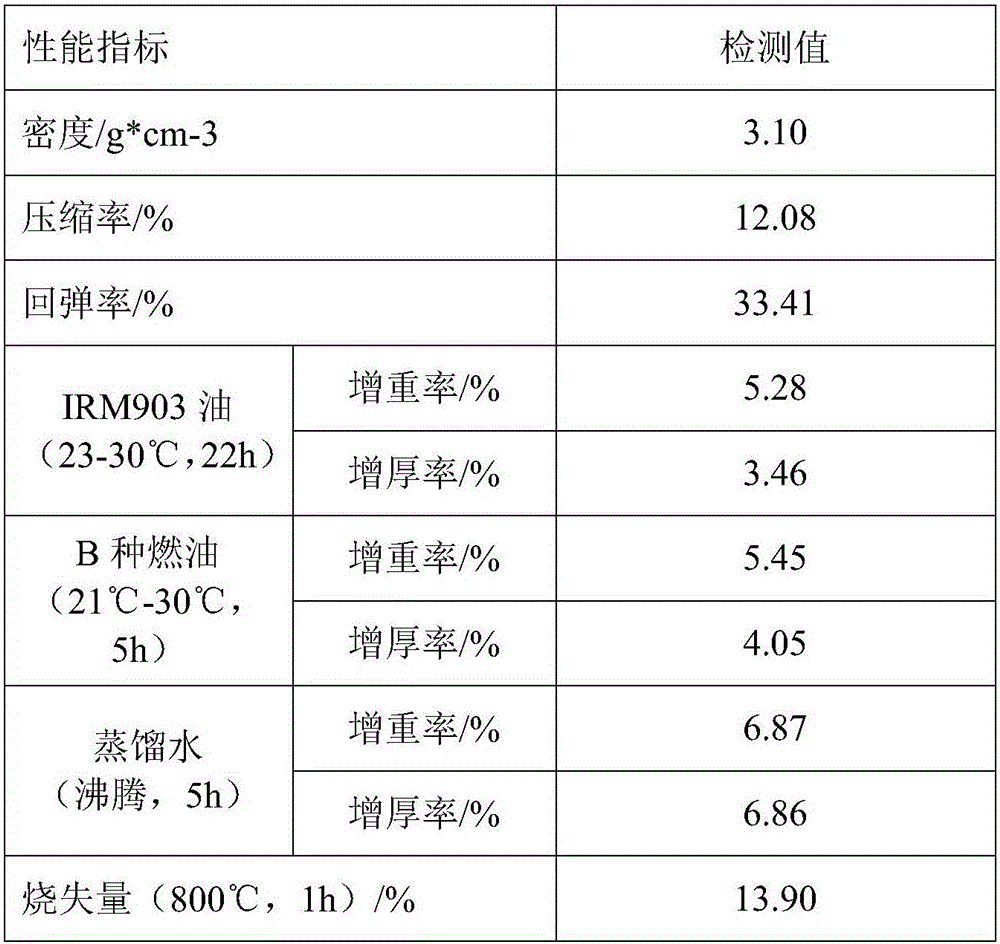

Embodiment 1

[0020] The formulas and proportions of the sealing material in the process of preparing the sealing material from the carbon fiber in this scheme include: 15% of carbon fiber, 10% of rubber emulsion and 75% of graphite powder.

[0021] The sealing material adopts the preparation method of drawing method and comprises the following steps:

[0022] Add water to the carbon fiber to fully disperse, and control the dispersion concentration of the carbon fiber at 4.5% to obtain a carbon fiber dilution; add graphite powder to the carbon fiber dilution, and fully stir to disperse the graphite powder and carbon fiber evenly; then, Slowly add the modified nitrile rubber, continue to stir after the addition of the modified nitrile rubber is completed, then add a compounding agent with a content of 5% of the modified nitrile rubber content, and stir evenly to obtain a slurry; The concentration is diluted to 1%, and at the same time, a retention aid with a concentration of 1‰ is added to t...

Embodiment 2

[0028] The formulas and proportions of the sealing material in the process of preparing the sealing material from the carbon fiber in this scheme include: 20% of carbon fiber, 25% of rubber emulsion and 55% of graphite powder.

[0029] The sealing material adopts the preparation method of drawing method and comprises the following steps:

[0030] Add water to the carbon fiber to fully disperse, and control the dispersion concentration of the carbon fiber within 4% to obtain a carbon fiber dilution; add graphite powder to the carbon fiber dilution, and fully stir to disperse the graphite powder and carbon fiber evenly; then, Slowly add the modified nitrile rubber again, continue stirring after the addition of the modified nitrile rubber is completed, then add a compounding agent whose content accounts for 5% of the modified nitrile rubber content, stir to obtain a slurry; The sizing concentration is diluted to 1%, and at the same time, a retention aid with a concentration of 1‰...

Embodiment 3

[0036] The formulas and proportions of the sealing material in the process of preparing the sealing material from the carbon fiber in this scheme include: 10% of carbon fiber, 17% of rubber emulsion and 73% of graphite powder.

[0037] The sealing material adopts the preparation method of drawing method and comprises the following steps:

[0038] Add water to the carbon fiber to fully disperse, and control the dispersion concentration of the carbon fiber within 4% to obtain a carbon fiber dilution; add graphite powder to the carbon fiber dilution, and fully stir to disperse the graphite powder and carbon fiber evenly; then, Slowly add the modified nitrile rubber again, continue stirring after the addition of the modified nitrile rubber is completed, then add a compounding agent whose content accounts for 5% of the modified nitrile rubber content, stir to obtain a slurry; The sizing concentration is diluted to 1%, and at the same time, a retention aid with a concentration of 1‰...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com